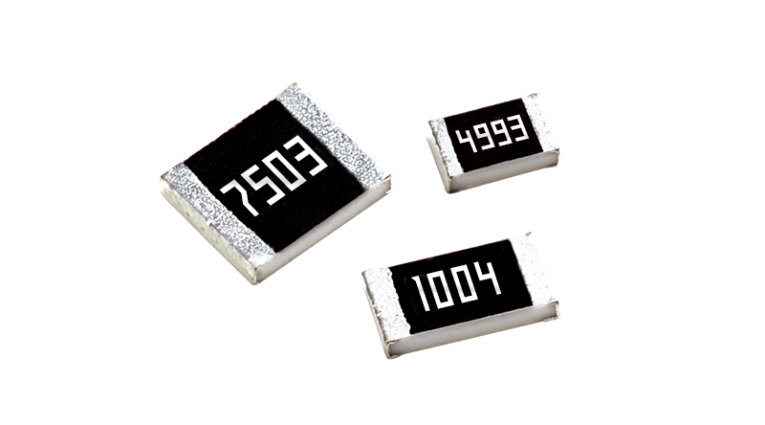

The so-called precision resistor mainly refers to a resistor with high precision in resistance value and low temperature coefficient, which has high long-term reliability and is widely used in measuring equipment. Therefore, the materials required for producing such high-precision resistors are also very special and the production process is strict. Below is an explanation of the commonly used materials for precision resistors:

Here are some common materials used for high-precision resistors:

Metal film is one of the commonly used materials for high-precision resistors. It is usually made by vacuum evaporating or sputtering a layer of metal alloy film on an insulating substrate such as ceramic or glass. Common metal film materials include nickel chromium alloys, etc. Metal film resistors have advantages such as high precision, good stability, and low temperature coefficient. Due to the uniformity and consistency of its thin film structure, it can provide accurate and stable resistance values. It has been widely used in measurement instruments, communication equipment, and other fields that require high resistance accuracy and stability.

Another important material is the metal wire used for wire wound resistors, commonly such as copper wire, manganese copper wire, etc. Wire wound resistors are made by winding metal wires around an insulating skeleton. This structure enables the wire wound resistor to withstand high power and has a low temperature coefficient and good long-term stability. However, the parasitic inductance of wire wound resistors is relatively large and may have some impact in high-frequency applications. Therefore, it is more suitable for DC or low-frequency circuits that require extremely high precision and stability, such as power circuits, precision measuring equipment, etc.

Carbon film is also one of the materials used in early high-precision resistors. It is made by decomposing hydrocarbons on a ceramic substrate to form a carbon film. Carbon film resistors have the characteristics of low cost and wide resistance range, but they are slightly inferior to metal film resistors in terms of accuracy and stability. However, in some general electronic devices that do not require particularly high precision, carbon film resistors still have certain applications.

Metal foil resistors are high-end products in high-precision resistors. It uses extremely thin metal foil as the resistance material, usually nickel chromium alloy foil. Metal foil resistors have extremely high precision, low temperature coefficient, and long-term stability. Due to its complex manufacturing process and high cost, it is mainly used in high-precision fields such as metrology standards with the strictest requirements for resistance performance, aerospace, etc.

In addition to the common materials mentioned above, there are also some new materials and composite materials that are constantly being researched and applied in the manufacturing of high-precision resistors. For example, some nanomaterials and conductive polymers have unique electrical properties that are expected to further enhance the performance of high-precision resistors in the future.

Different materials endow high-precision resistors with unique performance characteristics, enabling them to adapt to various application scenarios and needs. When choosing high-precision resistors, it is necessary to comprehensively consider various factors such as specific circuit requirements, working environment, accuracy requirements, and cost to determine the most suitable resistor material and type.

With the continuous development and progress of electronic technology, the performance requirements for high-precision resistors are also constantly increasing. This will drive continuous innovation in resistor manufacturing technology, as well as the research and application of new materials. In the future, we can look forward to seeing more high-performance and high-precision resistor materials emerge, providing more reliable and accurate support for the development of the electronic field.

In short, there are various materials for high-precision resistors, each with its unique advantages and applicable range. Understanding the characteristics of these materials is crucial for designing and selecting suitable high-precision resistors, which can help achieve high performance and reliability in electronic circuits.