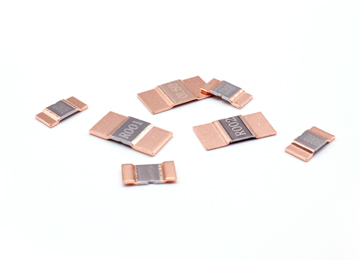

Resistors, as one of the fundamental components in circuits, play a crucial role. Among them, high-precision resistors are widely used in precision measurement, medical equipment, communication equipment, aerospace and other fields due to their high precision, low temperature coefficient, high stability and other characteristics. The performance of high-precision resistors largely depends on the selection of their materials. This article will delve into the common materials and characteristics of high-precision resistors.Precision resistor recommendation: Ellon ETR series.

Metal film material

Metal film material is the most common type of high-precision resistor. This material forms an extremely thin metal film on a ceramic or glass substrate through methods such as vacuum evaporation or sputtering, and then forms the desired resistance pattern through processes such as photolithography and etching. Metal film materials have the characteristics of high stability, low temperature coefficient, and high precision, making them suitable for applications that require high precision and stability. Common metal film materials include nickel chromium alloy, nickel copper alloy, etc.

Alloy material

Alloy material is also a commonly used type in high-precision resistors. Alloy materials are usually made by mixing two or more metal elements in a certain proportion, and have unique physical and chemical properties. In high-precision resistors, commonly used alloy materials include manganese copper alloy, nickel chromium alloy, etc. These alloy materials have characteristics such as low temperature coefficient, high precision, and high stability, making them suitable for applications that require high precision and low temperature coefficient.

Carbon film material

Carbon film material is a relatively traditional resistive material that forms a layer of carbon film on ceramic or glass substrates by high-temperature pyrolysis of organic compounds or hydrocarbon gases. Carbon film material has the advantages of low cost and simple process, but its accuracy and stability are relatively low, and it is generally suitable for situations where precision requirements are not high. However, by improving the process and material formulation, carbon film materials can also achieve higher precision and stability.

Thin film material

Thin film material is an emerging high-precision resistor material that forms an extremely thin metal or metal oxide film on ceramic or glass substrates through methods such as physical vapor deposition (PVD) or chemical vapor deposition (CVD). Thin film materials have the characteristics of high precision, low temperature coefficient, and high stability, making them suitable for applications that require extremely high precision and stability. Common thin film materials include nickel chromium alloy thin films, ruthenium oxide thin films, etc.

The material selection of high-precision resistors is crucial for their performance. Materials such as metal film, alloy, carbon film, and thin film have their own characteristics and are suitable for different application scenarios. With the continuous development of electronic technology, there is an increasing demand for precision, stability, and reliability of high-precision resistors. Therefore, the research and development of new materials and processes will become an important direction for the future development of high-precision resistors. Meanwhile, for high-precision resistors made of different materials, their manufacturing processes and parameter adjustments will also become key factors in improving resistor performance.

In practical applications, engineers need to choose suitable high-precision resistor materials and manufacturing processes based on specific application requirements and environmental conditions. Through reasonable material selection and process adjustment, high-precision resistors can ensure stable performance in various complex environments, providing reliable guarantees for the normal operation of electronic devices.