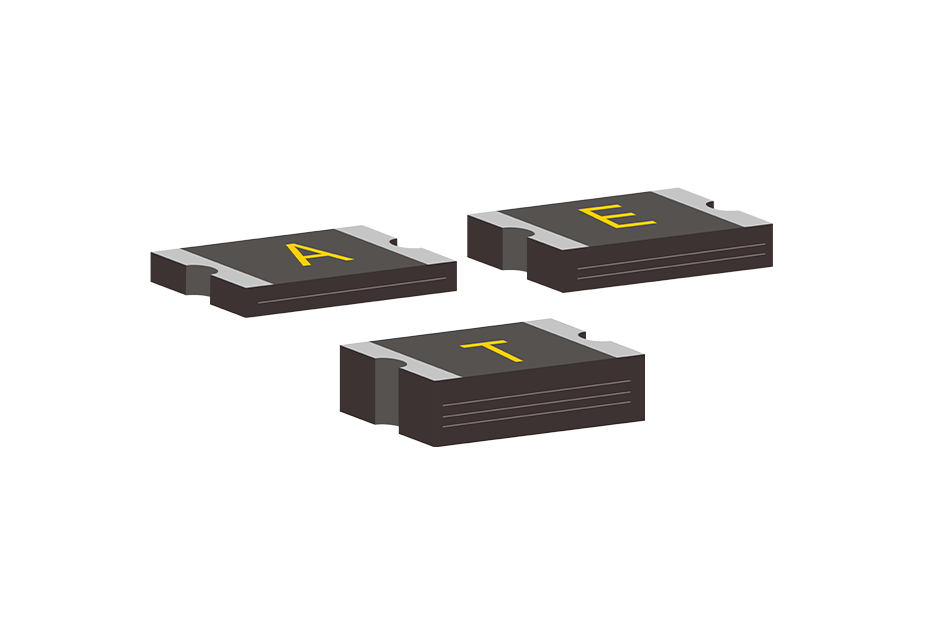

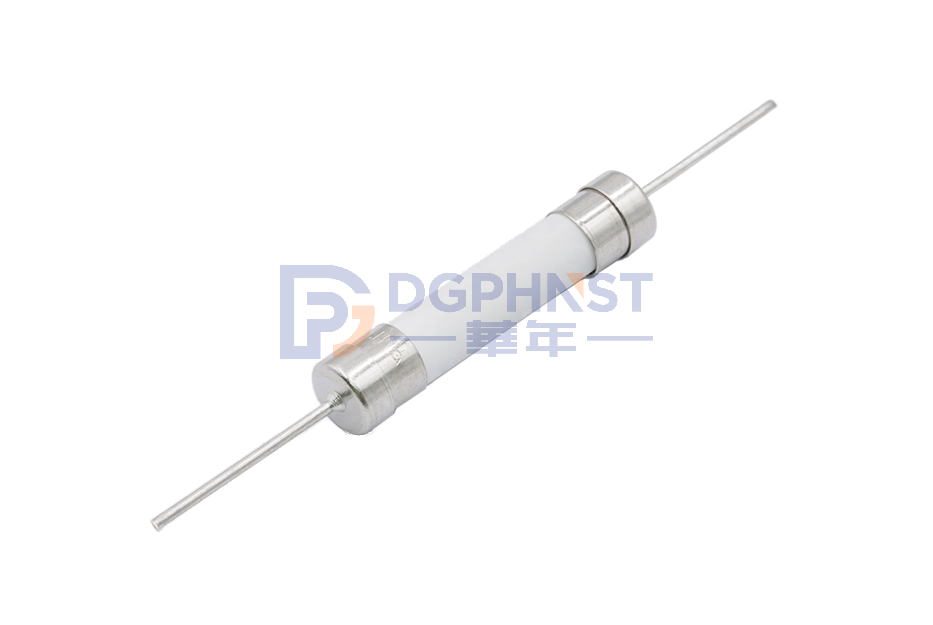

Fire Risk Analysis of Self Recovering Fuses (PPTC) in High Temperature Environments

1、 Material properties and thermal stability

Temperature resistance limit of polymer matrix

Conventional PPTC material thermal deformation temperature range: 120, 150 ℃ (UL certified model)

Critical decomposition temperature threshold: ≥ 200 ℃ (there is a difference of ± 20 ℃ among different formulations)

The dispersion of carbon black filler directly affects the thermal conductivity efficiency

Flame retardant performance indicators

Products that meet UL94 V0 standards can withstand 750 ℃ hot wire testing

The oxygen index of the shell material should be greater than 28% (to prevent continuous combustion)

Adding aluminum hydroxide flame retardant can enhance flame resistance

2、 Failure mode under high temperature conditions

Risk conditions for thermal runaway

Environmental temperature>85 ℃ and continuous overload current>3 times rated value

Multiple reset cycles (>100 times) lead to lattice structure degradation

Electrode interface delamination caused by thermal stress accumulation

Potential fire triggers

Electrode material oxidation leads to abnormal increase in contact resistance (Δ R>50%)

Cracking of packaging causes discharge arcing phenomenon

Secondary ignition caused by thermal radiation from adjacent components

3、 Design Specification for Safety Protection

Temperature compensation mechanism

Composite structure design with built-in NTC thermistor

Copper alloy electrode with temperature coefficient matching

Ladder type melting point protective layer (three-level response at 130/160/200 ℃)

Optimization of installation environment

Under forced air cooling conditions, a 15% increase in power density is allowed

The thermal resistance of the thermal conductive silicone gasket should be less than 1.5 ℃· cm ²/W

Reserve 2 times the regular safety distance in high-temperature areas

4、 Application Control Strategy

Temperature related derating curve

For every 1 ℃ increase above 40 ℃, the rated current decreases by 0.8% while maintaining the current

It is prohibited to exceed 75% of the nominal voltage in an environment of 70 ℃

Extreme temperature conditions require parallel TVS diodes for voltage clamping

Failure warning system

Integrated thermocouple for real-time monitoring of body temperature

Alarm triggered when impedance change rate exceeds 5%/min

Establish a thermal cycle counting life model

5、 Industry testing and verification standards

Hot abuse testing project

150 ℃ oven aging for 1000 hours for structural integrity testing

10 cold and hot shocks (40 ℃) ↔ 125 ℃) cyclic test

Surface infrared thermal imaging analysis under overload condition (hotspot < 180 ℃)

Fault safety verification

Apply twice the maximum voltage to verify that no open flame is generated

Conduct ultimate short-circuit test in a sealed container

Carbonization depth measurement (allowable value<30% section)

Conclusion: Self recovery fuses that meet industrial standards have no risk of fire when used within the rated temperature range, but exceeding the material's tolerance limit or being in a critical state for a long time may cause thermal failure. It is recommended to choose enhanced products (such as automotive grade AECQ200 certified models) for high-temperature applications, and to cooperate with temperature monitoring and heat dissipation design to reduce the probability of fire to<0.1ppm.