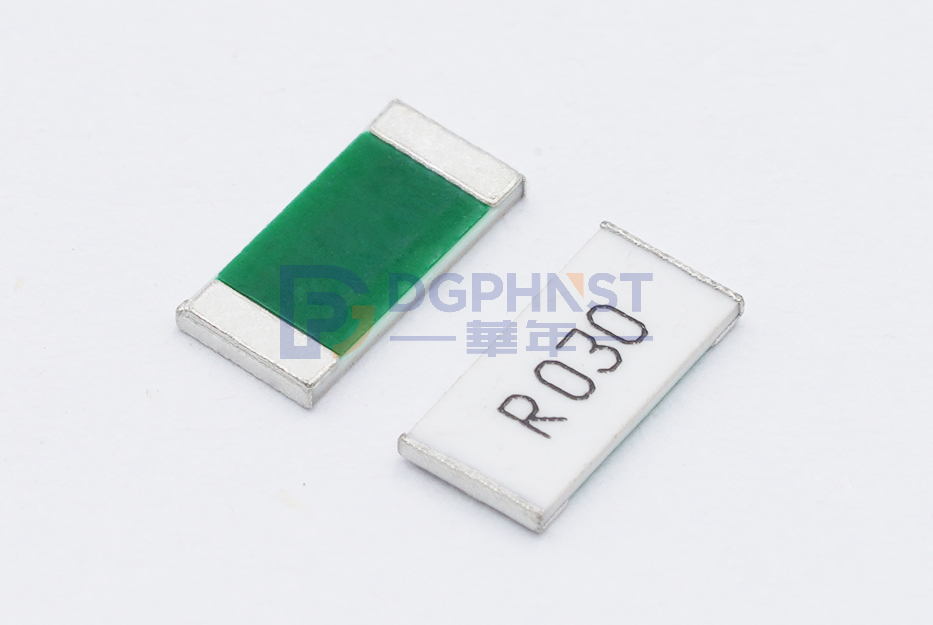

The STE-M-2010 is a high-performance metal foil current sensing resistor belonging to the STE-M-series, specifically engineered for precise current detection in a wide range of electronic applications. Crafted with premium materials and advanced manufacturing techniques, this resistor delivers exceptional electrical stability, reliable performance, and excellent environmental adaptability. It adheres to strict quality standards, making it an ideal choice for scenarios that demand accurate current measurement and stable operation under various working conditions.

Key Specifications

Dimensions (Unit: mm)

The STE-M-2010 features a standardized size with tight tolerances to ensure compatibility with most circuit designs. Its key dimensional parameters are as follows:

1. Width (W): 2.60±0.20

2. Length (L): 5.10±0.20

3. Thickness (T): 0.65±0.20

4. Parameter A: For resistance values 2~3mΩ (R002~R003), A is 2.10±0.30; for resistance values 4~9mΩ (R004S~R009S) and 10~700mΩ (R010~R700), A is 0.70±0.30

Electrical Characteristics

1. Resistance Value Range: 2mΩ ~ 700mΩ (Custom resistance values are available upon request)

2. Power Rating: 1.5 Watt (Continuous full-load operation at 70℃ ambient temperature)

3. Resistance Tolerance: For resistance values 2~9mΩ, tolerance is ±1% (F); for resistance values 10~700mΩ, tolerance options are ±0.5% (D) or ±1% (F)

4. Temperature Coefficient of Resistance (TCR): For resistance values 2~9mΩ, TCR is ±100 ppm/℃; for resistance values 10~700mΩ, TCR is ±50 ppm/℃

Environmental Characteristics

1. Operating Temperature Range: -55℃ ~ 155℃ (Power derating applies when operating above 70℃)

2. Storage Conditions:

2 years of storage in airtight packaging at 10℃~40℃ with relative humidity ≤75%

Up to 30 days of storage without dew at 10℃~60℃ with relative humidity of 95%

Product Structure and Materials

The STE-M-2010 is constructed with high-quality components to ensure durability and performance:

1. Substrate: Alumina Ceramic, providing excellent thermal conductivity and mechanical stability

2. Adhesion Layer: Epoxy resin, ensuring firm bonding between layers

3. Resistive Element: Copper alloy (Cu-alloy), delivering precise and stable resistance performance

4. Terminal Electrode: Composed of tin (Sn), nickel (Ni), and copper (Cu), ensuring reliable soldering and low contact resistance

5. Protective Coating: Flame-retardant epoxy resin (green) that meets UL-94-V0 requirements, offering effective protection against environmental factors

6. Marking Coating: Flame-retardant epoxy resin (black) that meets UL-94-V0 requirements, providing clear product identification

Reliability and Performance

The STE-M-2010 undergoes rigorous reliability tests to ensure consistent performance in demanding environments:

1. Short Time Over Load: Withstands 2.5 times the rated power for 5 seconds at 25±2℃, with resistance change within ±(1.0%+0.5mΩ)

2. High/Low Temperature Exposure: Maintains stability after 1000 hours at 155±2℃ (high temperature) or -55±2℃ (low temperature), with resistance change within ±(1.0%+0.5mΩ)

3. Moisture Load Life: Operates stably for 1000 hours (90min ON/30min OFF cycle) at 60±2℃ and 95% RH, with resistance change within ±(2.0%+0.5mΩ)

4. Thermal Shock: Endures 100 cycles of -55℃ (30min) → Room Temperature (3min) → 155℃ (30min) → Room Temperature (3min), with resistance change within ±(1.0%+0.5mΩ)

5. Solderability: Achieves over 95% solder coverage when dipped in solder at 245±5℃ for 3±1 seconds

6. Mechanical Stability: Resists mechanical shock (100G acceleration, 6ms duration) and substrate bending, with minimal resistance change

Soldering and Packaging Information

Recommended Soldering Pad Dimensions (Unit: mm)

1. P: For R002~R003, P=0.70mm; for R004S~R009S and R010~R700, P=2.70mm

2. W: 2.88mm

3. D: For R002~R003, D=3.65mm; for R004S~R009S and R010~R700, D=2.65mm

4. Loading: 1.5W (Suitable for recommended pad layout and specific steady current)

Soldering Conditions

1. Reflow Soldering: Compatible with IR, vapor phase, or hot air reflow methods (follow recommended temperature profile)

2. Rework Temperature: 350℃ for 3~5 seconds (hot air equipment)

3. Note: Exceeding recommended soldering temperatures may damage the product

Packaging Specifications

1. Quantity per Reel: 4,000 pieces

2. Weight per Reel: 210±40 grams

3. Reel & Tape Specifications: A=178±5mm, N=60±2mm, W1=13±1mm

4. Seal Tape Peeling Strength: 0.1~1.0 N (10~100 gf) at 165~180°

Conclusion

The STE-M-2010 metal foil current sensing resistor stands out for its precise resistance control, excellent temperature stability, and robust reliability. Its compact size, standardized dimensions, and versatile performance make it suitable for a wide array of applications, including power management systems, industrial controls, automotive electronics, and consumer electronics. Whether in harsh environmental conditions or high-precision measurement scenarios, the STE-M-2010 consistently delivers accurate and stable current sensing capabilities. Backed by strict quality control and comprehensive testing, this resistor is a trustworthy component that meets the demanding requirements of modern electronic systems, providing designers and manufacturers with a reliable solution for their current detection needs.

HNST WELCOME! 0755-23173910

English |中文

你当前的浏览器版本过低或不支持。请升级或更换浏览器。推荐浏览器 Chrome Edge。