hnstshop.com/" target="_blank" rel="noopener">Resistors are common electronic components used for controlling current flow and adjusting circuit parameters. They can be classified into different types based on the material used. Let's explore some of the major resistor types based on material:

1. Carbon Film Resistor:

Carbon film resistors are widely used and are made by depositing a carbon film on a ceramic substrate. They offer moderate precision and stability and are cost-effective. Carbon film resistors are commonly used in general electronic applications.

2. Metal Film Resistor:

Metal film resistors are made by depositing a thin metal film, typically nickel-chromium or tin-copper alloy, on a ceramic substrate. They provide high precision, stability, and low noise performance. Metal film resistors are suitable for applications that require high accuracy and low noise, such as measurement instruments, communication equipment, and precision control systems.

3. Metal Oxide Film Resistor:

Metal oxide film resistors are made by depositing a metal oxide film, such as tin oxide (SnO2) or tungsten oxide (WO3), on a ceramic substrate. They offer high power handling capability, stability, and temperature characteristics. Metal oxide film resistors are suitable for high-power and high-temperature circuit applications.

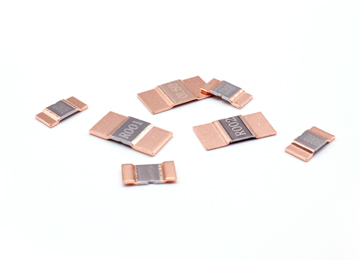

4. Metal Strip Resistor:

Metal strip resistors are made using a metal strip as the resistance element. They provide high power handling capability and stability, making them suitable for high-temperature and high-humidity environments. Metal strip resistors are commonly used in industrial applications and specialized circuit environments.

5. Thick Film Resistor:

Thick film resistors are made using a ceramic material with higher conductivity. A thick film material is deposited on the surface of the resistor body to achieve the desired resistance value. Thick film resistors offer high power handling capability and stability. They are widely used in various electronic devices and circuits. Thick film resistors are cost-effective and suitable for mass production and general applications.

6. Thin Film Resistor:

Thin film resistors are made by depositing a thin film material on a ceramic substrate. They offer high precision, stability, and low noise performance. Thin film resistors are suitable for applications that require high accuracy and low noise, such as measurement instruments, communication equipment, and precision control systems.

7. Thick Film and Thin Film Resistors:

Thick film resistors and thin film resistors differ in manufacturing processes and performance characteristics. Thick film resistors are suitable for cost-sensitive applications, while thin film resistors are more suitable for high-precision and high-performance applications. The choice between thick film and thin film resistors depends on specific design requirements and performance needs, ensuring circuit stability and reliability.

These are some common types of resistors based on material classification. Each type has its specific characteristics and suitable applications. Understanding different resistor types helps us better comprehend their properties and application areas, enabling us to make informed choices in circuit design.