History of Jiangsu Changdian Technology Brand: From Local Innovation to Global Leadership

As a leading enterprise in the field of semiconductor packaging and testing in China, Jiangsu Changdian Technology Co., Ltd. (referred to as "Changdian Technology") has closely intertwined its brand growth with the rise of China's integrated circuit industry. From a local factory to one of the top three global packaging and testing giants, every step taken by Changdian Technology reflects the transformation trajectory of China's semiconductor industry from technological catch-up to independent innovation.

1、 Start up and Transformation Period (1972-2000): Localized Technology Accumulation

The predecessor of Changdian Technology can be traced back to Jiangyin Transistor Factory established in 1972, which initially focused on the production of discrete devices. In the 1990s, with the upgrading of China's electronic information industry, enterprises keenly grasped the potential of the semiconductor packaging market and gradually shifted their business focus to the field of integrated circuit packaging. By introducing and digesting overseas technology, the first domestically produced SOP packaging production line was successfully developed in 1998, laying the foundation for future development. In this stage, the brand core is "technology domestic substitution", establishing a strategic positioning based on the local market.

2、 Capital Driven and Technological Upgrading (2001-2014): Listing Promotes Scale Development

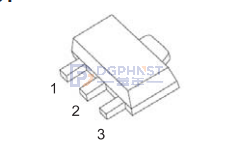

The listing on the Shanghai Stock Exchange in 2003 became a crucial turning point. With the help of capital, the company has invested in the construction of high-end packaging production lines such as BGA and QFN. In 2010, it built the first 12 inch wafer level packaging production line in China, achieving a technological leap from traditional packaging to advanced packaging. At this point, the brand positioning has been upgraded to "China's high-end packaging and testing solution provider", gradually building industry chain synergy advantages by undertaking orders from local chip design companies such as Huawei and ZTE. In 2014, the revenue exceeded 1 billion US dollars, ranking among the top six global testing companies.

3、 Internationalization Layout Stage (2015-2020): Mergers and Acquisitions Integration Reshaping the Industry Landscape

In 2015, it acquired Singapore's STATS ChipPAC for $780 million, becoming the first classic cross-border merger and acquisition case in China's semiconductor industry. This acquisition not only obtained core technology patents such as FCBGA and SiP, but also expanded its customer base to international giants such as Apple and Qualcomm, and its global market share jumped to third place. Afterwards, by restructuring the Korean factory and establishing a research and development center in Singapore, a dual manufacturing base layout of "China+Southeast Asia" was formed. The brand image has thus transformed into a "global technology service provider", with advanced packaging accounting for over 40% of revenue in 2020.

4、 Technology leadership and ecological construction (2021 present): Innovation driven full chain collaboration

Faced with new demands for 5G, AI, and automotive grade chips, Changdian Technology has taken the lead in laying out cutting-edge technologies such as Chiplets and 2.5D/3D packaging, and will achieve mass production of 4nm chip packaging by 2022, XDFOI ™ The technology has been certified by international top customers. By constructing a Shanghai Lingang vehicle specification level testing base and jointly building a 12 inch middle lane production line with SMIC, we aim to deeply integrate with the domestic chip manufacturing ecosystem. By 2023, the global market share will reach 10.3%, forming technical barriers in segmented fields such as 5G RF and high-performance computing, and the brand value will transition towards being a "leader in system level packaging and testing solutions".

Core Development Logic and Future Prospects

The brand growth of Changdian Technology follows the evolutionary path of "technology self-reliance - scale capitalization - resource globalization - innovation ecology", and its core competitiveness is reflected in three aspects:

R&D investment: With an average annual R&D intensity of over 5%, we have over 3000 patents;

Manufacturing network: 8 global production bases with packaging capabilities covering 3nm nodes;

Ecological synergy: Deeply integrating into the domestic semiconductor industry chain, building a closed-loop system of chip design manufacturing packaging and testing.

In the future, with the development of Chiplet technology standards and the explosive demand for AI chip packaging, Changdian Technology is accelerating its layout in new tracks such as heterogeneous integration and optoelectronic co packaging (CPO). Its brand strategy goal has shifted from being a "follower" to a "rule maker", committed to becoming a core participant in the global semiconductor industry ecosystem.

(This article is based on publicly available information and industry analysis, with data updated until Q3 2023)