Are bare copper resistors and alloy resistors the same in function? (Recommended for the Ellon ESR series)

In the field of electronic components, resistance is a crucial fundamental component. When engineers are designing circuits, especially high-power circuits, bare copper resistors and alloy resistors are two common choices. So, are their functions exactly the same? The answer is: they are consistent in their core resistance function, but there are significant differences in specific applications, performance characteristics, and applicable scenarios.

Core Function: Current Limitation and Energy Conversion

From the most fundamental principles of physics, the main function of any resistor is to impede the flow of current and convert excess electrical energy into thermal energy. Both bare copper resistors and alloy resistors possess this core function. They are all used to control the current size in circuits, set appropriate operating points, perform sampling measurements, or serve as load power consumption.

The unique features of bare copper resistors

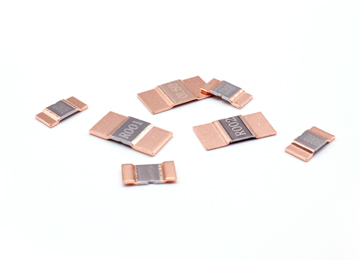

Bare copper sheet resistors, as the name suggests, are sheet resistors made from high-purity copper materials through precision machining. One key characteristic of it is its extremely low resistance value. Due to copper being an excellent conductor, the resistance of bare copper sheet resistors is usually only in the milliohm or even micro ohm range.

Therefore, the core function of bare copper resistors focuses on current detection under high currents and providing small voltage drops. It is often used as a sampling resistor, connected in series in the power path. When a large current flows, according to Ohm's law, a small voltage signal proportional to the current will be generated at both ends. This signal is sent to the control chip (such as MCU or dedicated current monitoring IC) to achieve precise monitoring and protection of the system current. Due to its single material, bare copper resistors have relatively low costs and economic advantages in large-scale applications.

Comprehensive performance of alloy resistors

Alloy resistors are a broader category, typically made of alloy materials composed of metals such as copper, manganese, nickel, etc. The fundamental difference in this material endows the alloy resistance with a wider range of properties.

Firstly, alloy resistors can achieve a wide range of resistance values ranging from milliohms to tens of ohms, and their application scenarios are far more diverse than bare copper resistors. Secondly, alloy resistance materials typically have an extremely low temperature coefficient, which means that their resistance value fluctuates very little with changes in ambient temperature. This is crucial for measurement circuits that require high precision and stability. In addition, advanced alloy resistors often outperform pure bare copper sheet resistors in terms of long-term stability, pulse impact resistance, and power density.

Function Comparison and Selection Guide

We can understand their functional focus as follows:

Bare copper resistance: more like a 'specialist'. Its functions are specialized in high current, low-cost, milliohm level sampling and current detection. Bare copper sheet resistors are an ideal choice for cost sensitive and high current applications, such as motor drives for electric vehicles and bus current detection for UPS power supplies.

Alloy resistance: more like a 'generalist'. Its functions cover multiple aspects such as precision sampling, current limiting, pulse absorption, and power consumption. Especially in situations that require high precision, high stability, and tolerance to harsh environments, such as industrial frequency converters, precision instruments, automotive electronic control units, etc., alloy resistors have become the preferred choice due to their excellent comprehensive performance.

summary

In summary, although bare copper resistors and alloy resistors both serve the basic function of resistance, their functional positioning is not the same. Bare copper resistors focus on the specific function of high current sampling due to their extremely low resistance and cost advantages. Alloy resistors, on the other hand, provide a more comprehensive and stable range of functions, from precision sampling to power processing, thanks to the superiority of their materials. Therefore, when choosing, engineers need to determine which resistor can better meet their functional requirements based on the specific requirements of the circuit for resistance, accuracy, stability, and cost.