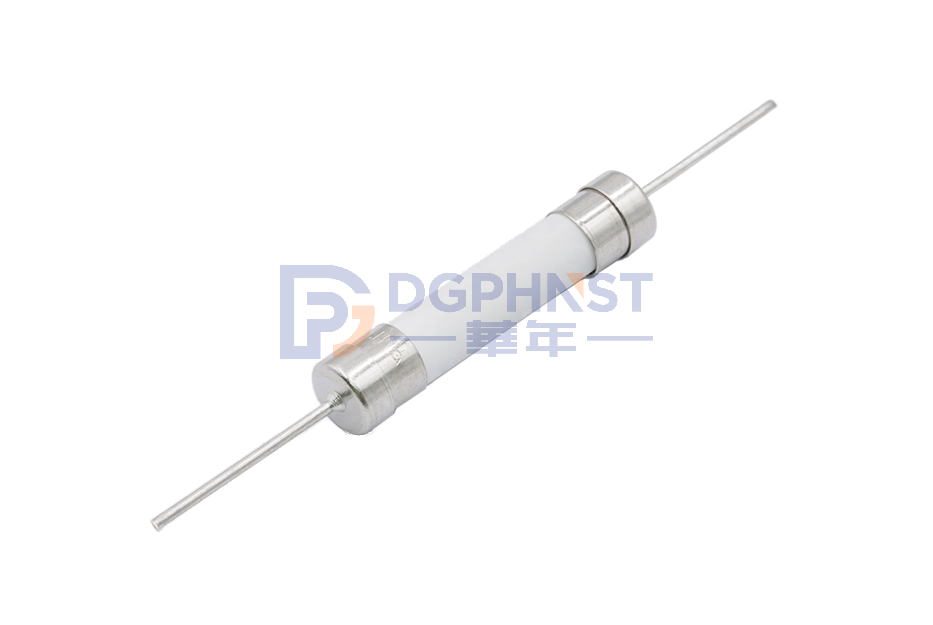

Xu cheng fuse in the rail vehicle traction technology, is to protect the circuit and equipment from the damage of the current and overvoltage, with the development of power electronic devices, the whole industry power fuse has experienced a series of changes, from the earliest mechanical hnstshop.com/" target="_blank">fuse to modern solid state fuse, the protection circuit ability and response speed has been significantly improved. Such as xu cheng 10C series, this series of rated voltage 500V, current of 100 mA-32A, specification 10X38mm, fast fuse speed, material environmental protection, a wide range of application, there are many advantages.

Fuse 10C series in the track vehicle traction technology, The AC transmission system has many advantages, For example, it can improve traction efficiency, reduce mechanical wear, reduce maintenance costs, Power electronics in AC transmission systems are also facing the threat of overcurrent and overvoltage, Therefore, the need to use a power fuse for protection, With the development and maturity of GTO (portal shutdown thyristor) devices, Significant progress has also been made in the development of MOS (metal oxide semiconductor field effect) devices, Insulated gate bipolar transistors (IGBT) have become a leader in power electronic devices, Combining the advantages of the GTO and MOS, The 10C fuse has the advantages of high voltage, high current, high frequency and easy control, Therefore, it has been widely used in the rail vehicle traction technology.

After entering the 1990s, power electronic devices began to develop in the direction of intelligence and modularization, and strive to integrate power devices with drive circuit, protection circuit and detection circuit in a chip or module, so as to make the device more small and intelligent. In this process, the 500V power fuse still plays the role of protector, and the guarantee of its quality is crucial to the safety of the whole circuit. In order to ensure the quality of the power fuse, the manufacturer needs to carry out strict control and testing in the production process, such as the use of advanced materials and technology, high and low temperature testing, aging test, etc. In the use process, it also needs to choose the appropriate models and specifications according to the actual demand, and conduct regular inspection and maintenance.