The design of the battery protection board (BMS, battery management system) for outdoor energy storage power sources needs to comprehensively consider safety, stability, and intelligent management requirements. The following is an analysis of mainstream design solutions and technical points in the industry:

1、 Core hardware protection mechanism

Voltage protection module

Adopting dual channel voltage detection chips (such as TI BQ769 series)

Lithium iron phosphate battery pack: overcharge protection point 3.65V ± 0.02V, over discharge protection 2.5V ± 0.05V

Ternary lithium battery pack: overcharge protection 4.25V ± 0.03V, over discharge protection 2.8V ± 0.05V

Support single cell voltage difference balance, with a threshold usually set within 30mV

Current protection system

Parallel splitter+high-precision operational amplifier (0.5% accuracy)

Overcurrent protection graded response: short-time overload (>1.5C) delayed cut-off, severe overload (>3C) millisecond level protection

Support reverse charging protection, response time<100 μ s

Temperature protection system

Multi point NTC thermistor layout (key positions on cell surface/PCB)

Working temperature range: 20 ℃~60 ℃ (industrial grade devices)

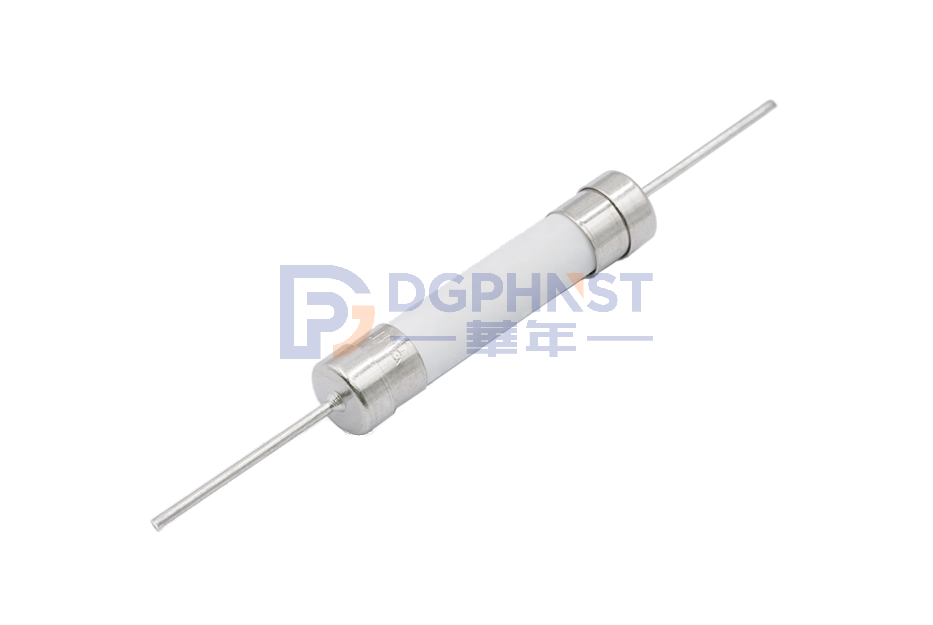

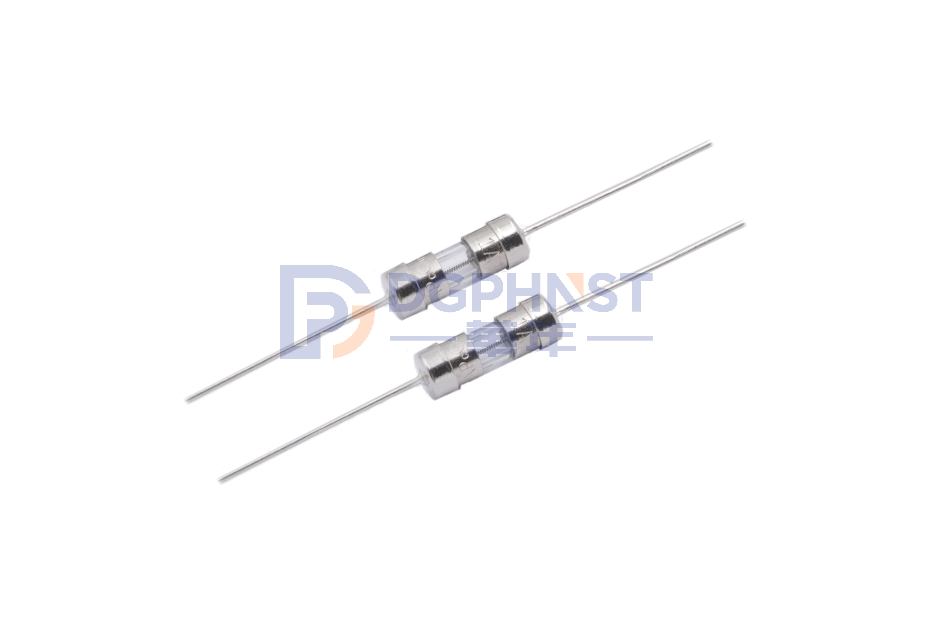

Gradient temperature control strategy: 45 ℃ current limiting → 55 ℃ power-off → 65 ℃ fuse protection

2、 Intelligent management function

active equalization technology

Active balancing current can reach 2A (such as LTC3300 scheme)

Support full cycle balancing of charging/settling/discharging

Coulombometer accuracy ± 1% (with MAX1704x chip)

Fault self diagnosis system

Real time monitoring of MOSFET on impedance (accuracy 5m Ω)

Automatically record abnormal events (EEPROM stores 1000 logs)

OTA firmware upgrade interface (via CAN/RS485)

3、 Structural protection design

Three proof coating treatment (compliant with IP67 standard)

Seismic buffering structure (tested by 5Grms vibration)

Anti reverse circuit design (withstand 24V reverse connection for 10 minutes)

4、 Communication protocol support

Standard UART/I2C local interface

Optional Bluetooth 5.0/WiFi module

Supports Modbus RTU/CAN 2.0B protocol

5、 Certification requirements

Safety standards: UL 2054/IEC 62619

Electromagnetic compatibility: EN 55032/EN 61000

Transportation certification: UN38.3

Current high-end solution trends:

Integrated AI prediction algorithm (cycle life estimation)

Support photovoltaic MPPT linkage control

Graphene heat sink+heat pipe composite heat dissipation system

This design has been tested in outdoor power sources with a capacity of 2000W/2000Wh and has been shown to increase battery cycle life to 3000 times (80% capacity retention rate), with system reliability reaching the MTBF 100000 hour level. In actual development, it is necessary to focus on optimizing sampling synchronization (<10 μ s delay) and static power consumption (<50 μ A), which is crucial for extending standby time.