Detailed explanation of the recovery mechanism and triggering conditions of self recovering fuses (PPTC)

1、 Core recovery principle

Characteristics of phase change materials

Polymer matrix exhibits an amorphous state (high resistance state) at high temperatures

When the temperature drops to the Curie point (about 85125 ℃), it returns to the crystalline state (low resistance state)

The lattice reconstruction time is positively correlated with the material's heat capacity

2、 Essential recovery conditions

Power interruption requirements

Completely disconnect the overload current (residual current should be less than 5% of the rated value)

The system voltage needs to be reduced to below 10% of the operating voltage

Multi channel power supply system needs to ensure circuit isolation

Temperature attenuation specification

The body temperature needs to be reduced to below 65% of the triggering temperature

Recommended natural cooling rate>2 ℃/s

Allow forced heat dissipation (such as air-cooled/cooling fins)

Time threshold requirement

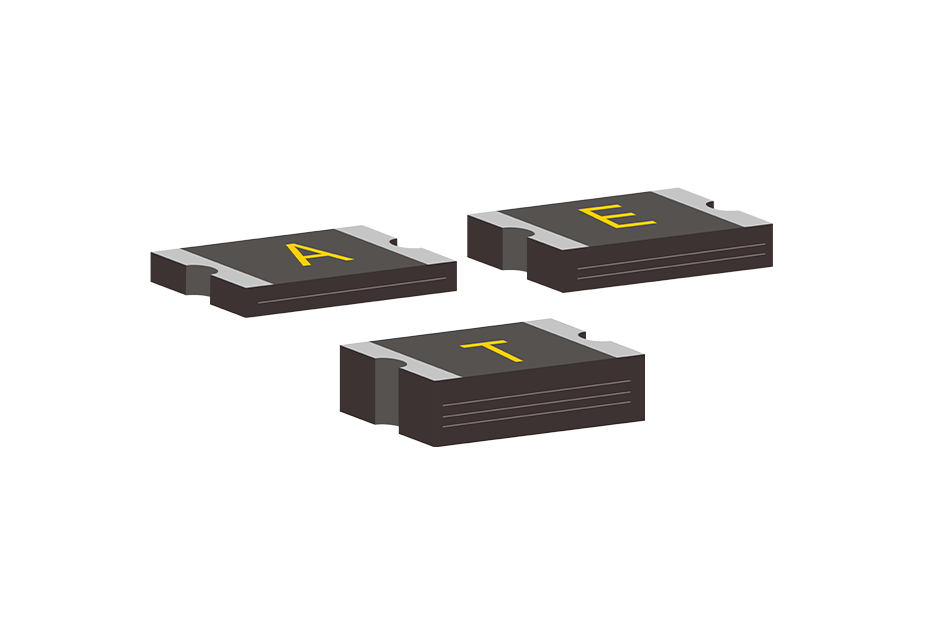

Minimum recovery time: 30 seconds (thin patch packaging)

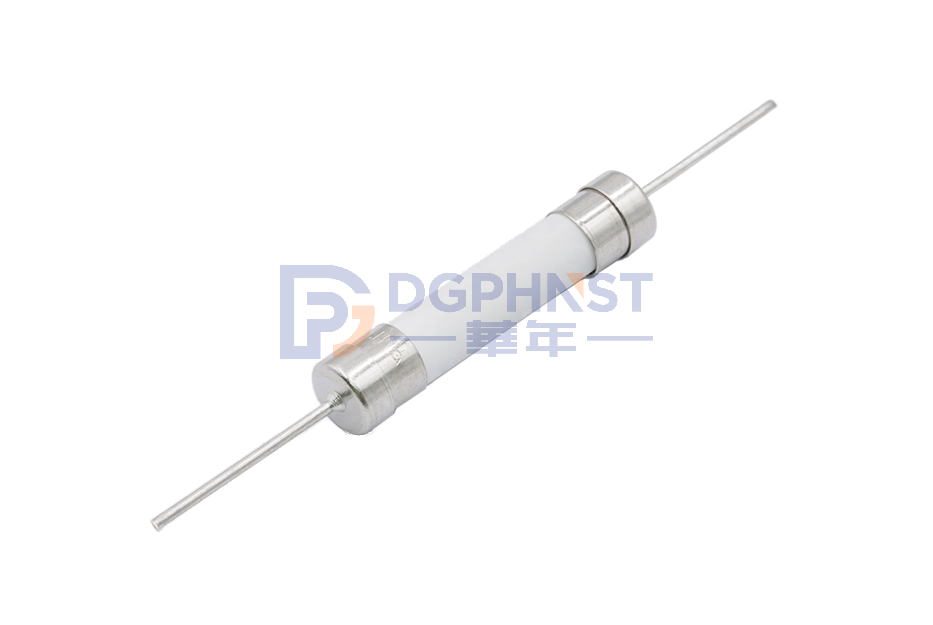

Typical recovery time: 13 minutes (standard industrial grade product)

Maximum recovery time: ≤ 10 minutes (compliant with UL certification standards)

3、 Factors affecting restoration quality

Electrical parameter constraints

The restart current must be less than 80% of the holding current (IH)

The voltage rise rate should be less than 5V/ms (to prevent secondary triggering)

Suggest setting a 10 second delay restart circuit

Aging state of materials

Actions less than 100 times can ensure a 90% recovery rate

Aging calibration is required for storage time>5 years

Migration of carbon black filler exceeding 30% will result in permanent failure

4、 Special scenario recovery strategy

Low temperature environment restoration

Preheat below 20 ℃ to above 0 ℃

Using pulse current assisted heating (pulse width<10ms)

Prohibition of forced reset by mechanical external force

High density installation recovery

When the distance between adjacent components is less than 5mm, the cooling time needs to be extended by 50%

Multi layer PCB requires the installation of a thermal conductive via array

Heat exchange ducts need to be installed in enclosed spaces

5、 Restore verification standards

Electrical performance testing

Impedance after recovery ≤ 1.5 times the initial value (measured at 25 ℃)

Insulation resistance>100M Ω (tested at 500VDC)

Dielectric withstand voltage test passed twice the rated voltage

Structural integrity check

No visible deformation (detected at 20x magnification)

Electrode adhesion>5N/mm (tensile test)

Encapsulation airtightness maintenance (helium mass spectrometry leak detection)

Note: Complete recovery requires both thermodynamic equilibrium and electrical stress relief conditions to be met simultaneously. It is recommended to configure a recovery status monitoring module for critical systems, which can detect impedance change curves in real time. When the recovery degree reaches 85% or above, the system can be allowed to restart. Root cause analysis is required for multiple abnormal triggers (>3 times within 24 hours).