In order to meet the new energy efficiency standards for air conditioning and achieve the major strategic goal of "dual carbon" energy conservation and emission reduction advocated by the country as soon as possible, it is of great strategic significance and economic benefits to further improve the energy efficiency of HVAC systems in today's extremely high usage and electricity consumption of variable frequency air conditioning.

In the past decade, silicon carbide MOSFETs have been gradually applied in large quantities in fields such as switching power supplies, photovoltaic power generation, electric vehicles, high-speed railways, and power grids. The reliability and cost-effectiveness have been greatly improved and fully verified by the market. A large number of facts indicate that the new era of third-generation semiconductor represented by silicon carbide has arrived.

The new semiconductor technology represented by silicon carbide provides a new way to improve the comprehensive performance of HVAC systems. It can not only further optimize system performance, but also significantly improve system efficiency, helping HVAC meet or even exceed new energy efficiency standards, making HVAC systems more cost-effective.

Project Introduction:

This project is provided by the technical solution provider of the Achievement Transformation and Technology Transfer Service Platform of Huaqiang Electronics Industry Research Institute.

In order to cope with the new standards in the HVAC industry and the winter range anxiety of electric vehicles, the project solution company proposed a compressor controller solution based on a new power device silicon carbide MOSFET, and designed a 16kW level controller prototype for verification.

The verification results indicate that applying SiC MOSFET to HVAC systems in this project not only significantly improves system performance, but also has more advantages in terms of cost-effectiveness.

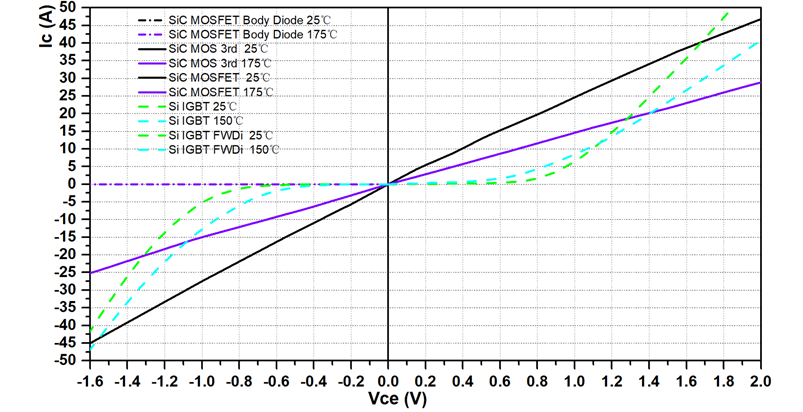

Better energy-saving effect: As shown in the figure below, silicon carbide MOSFET has no inflection point voltage, only a certain on resistance, and the on voltage is linearly related to the current, thus greatly reducing the on voltage drop and loss. When the HVAC system operates under stable conditions, the compressor controller will work in light or ultra light load mode, resulting in better energy-saving effects.

Figure 1 Comparison of conduction characteristics between silicon carbide MOSFET and traditional silicon IGBT

Higher system efficiency: The project company's R&D team used open power and efficiency iPowerSiM simulation software to simulate a 16kVA compressor controller prototype, which uses a 40m Ω, 1200V silicon carbide MOSFET from Wolfspeed. The simulation results show that even at a high switching frequency of 16kHz, the efficiency can reach as high as 98.6%.

Figure 2 Power consumption and efficiency simulation of 16kW silicon carbide controller based on iPowerSiM simulation software

The prototype of the solution not only increases the switching frequency, but also appropriately reduces the voltage change rate, avoiding the shaft current and damage to winding insulation caused by high dv/dt of silicon carbide. Even so, the controller can still achieve a peak efficiency of 98%, which is 0.5% higher than the efficiency of traditional silicon IGBT under full load, and 1% -5% higher than the efficiency under light load and ultra light load.

Figure 3: Efficiency Curve and Comparison of Silicon Carbide Controllers

Compatibility and cost control are balanced: In order to reduce costs, the prototype of the solution also adopts the commonly used bootstrap power supply mode in the air conditioning industry, and generates negative voltage for silicon carbide gate driving under the circuit and control strategy with independent intellectual property rights, improving the gate reliability of silicon carbide MOSFET, while also considering the application habits, volume, and cost control of the air conditioning industry.

Application scenarios:

The technology of this project can be applied to residential and commercial HVAC systems, as well as electric vehicle HVAC systems.

Commercial HVAC: The C3M0040120K silicon carbide MOSFET used in the prototype of this project scheme is almost as expensive as silicon IGBT modules and superior to IPM modules. It achieves better performance without increasing system costs, and has extremely high practical significance. If we consider the cost reduction of heat dissipation systems, sound insulation systems, etc. due to the use of silicon carbide devices, as well as the electricity consumption caused by high efficiency and low loss, that is, the most intuitive electricity cost reduction, the prototype of the solution has extremely high economic value.

Application of electric vehicles: In recent years, electric vehicles have flourished like mushrooms after rain, but the significantly reduced range of electric vehicles in winter has been criticized by users. One of the reasons is that most electric vehicles use PTC (Positive Temperature Coefficient) resistance heaters for winter heating function. Even when the COP (Coefficient of Performance) heating efficiency ratio of PTC is close to 1, about 30% -50% of battery power will still be used for heating, which will cause a significant reduction in range. However, if a wide temperature range and high-efficiency silicon carbide heat pump air conditioning system is adopted, the energy efficiency can be reduced by more than 60%. The energy efficiency ratio COP under winter heating conditions can reach 2-4, which is several times higher than the current PTC heating method, and can bring a maximum winter range improvement of about 25%.

Technical advantages:

System efficiency increased by 1% -5%

Reduce energy loss by 40%

Increase the switching frequency by 100% -200%

Reduce dead time by 60%

Good energy-saving effect

Independent research and development

Stable performance

Support customized development

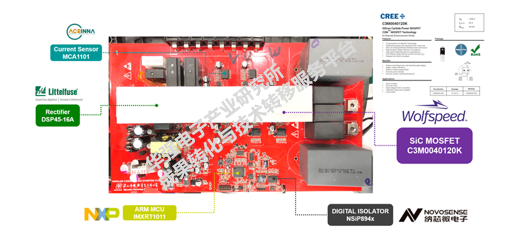

Product sample image:

g" width="515" height="243" loading="lazy" />

g" width="515" height="243" loading="lazy" />