Outdoor power supply is a rapidly emerging portable energy storage solution that facilitates outdoor travel and emergency home energy storage. Especially for outdoor travel, the application of outdoor energy storage is very extensive, and it is also one of the essential items for self driving and outdoor travel. Below is a disassembly and explanation of a 2000W alloy resistor and fuse for outdoor energy storage. (Content and Image Source: Charging Head)

One end of the body is equipped with a display screen, USB, DC, and AC function output interfaces. Each functional module is equipped with an independent key control, making it more flexible, energy-efficient, and safe to use. Each type of functional socket module area is equipped with rubber protective covers that are dustproof and waterproof, and are printed with corresponding interface labels for easy differentiation and use by users.

Model: M2000 (Quasi Solid State Lithium ion Battery Pack)

Capacity: 2008.8Wh, 32.4V/62Ah

USB-A(x2):5V2.4A

USB-A QC3.0(x2):5/9/12/15/20V3A 60W Max

USB-C PD3.0(x2):5/9/12/15/20V5A 100W Max

Car charging port output: 12.6V12A

DC 5521 output (x2): 12.6V6A

Communication output (x3): 220V/50Hz 2000W

AC input: 180-240V 1200W Max

Solar input: XT60 18-50V 1000W Max

Car input: XT60 12.5-15V 100W Max/33-40V 500W Max

Environmental temperature: -30 ℃~40 ℃

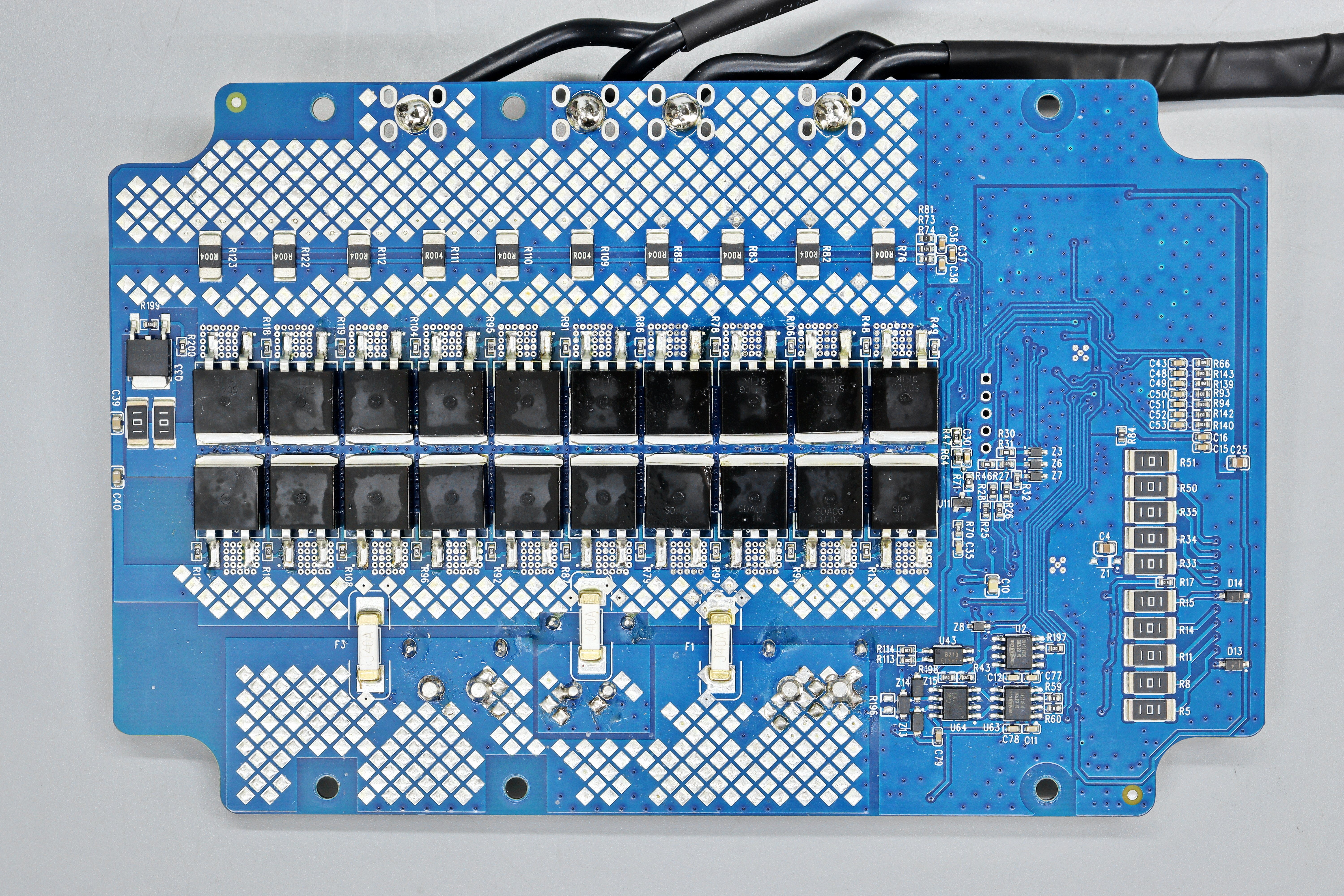

Weld the battery protection tube, fuse, and current sampling resistor on the back of the battery protection board (BMS), and weld the isolation communication chip and battery balancing resistor on the right side.

The battery protection board (BMS) is equipped with 10PCS of 2512 0.004R (4mR) alloy resistors, recommended model: EMA25F3W0R010FDG, and 3PCS disposable patch fuses 1032 60A fuses.

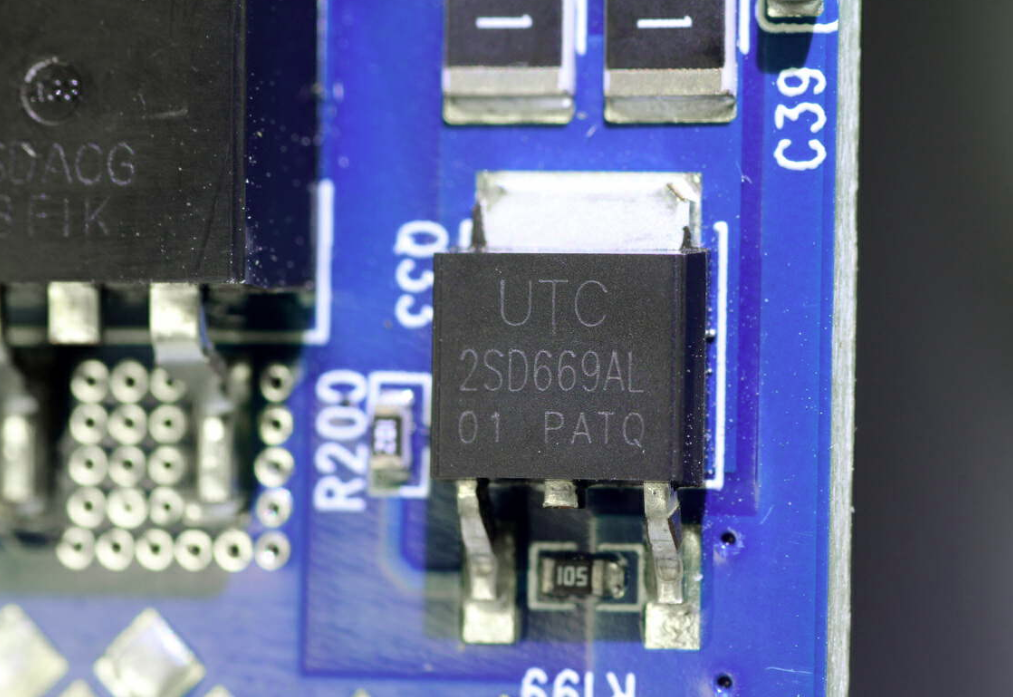

The transistor used for pre charging control is from UTC Youshun, model 2SD669A, NPN type, withstand voltage of 160V, collector current of 1.5A, and packaged in TO252.

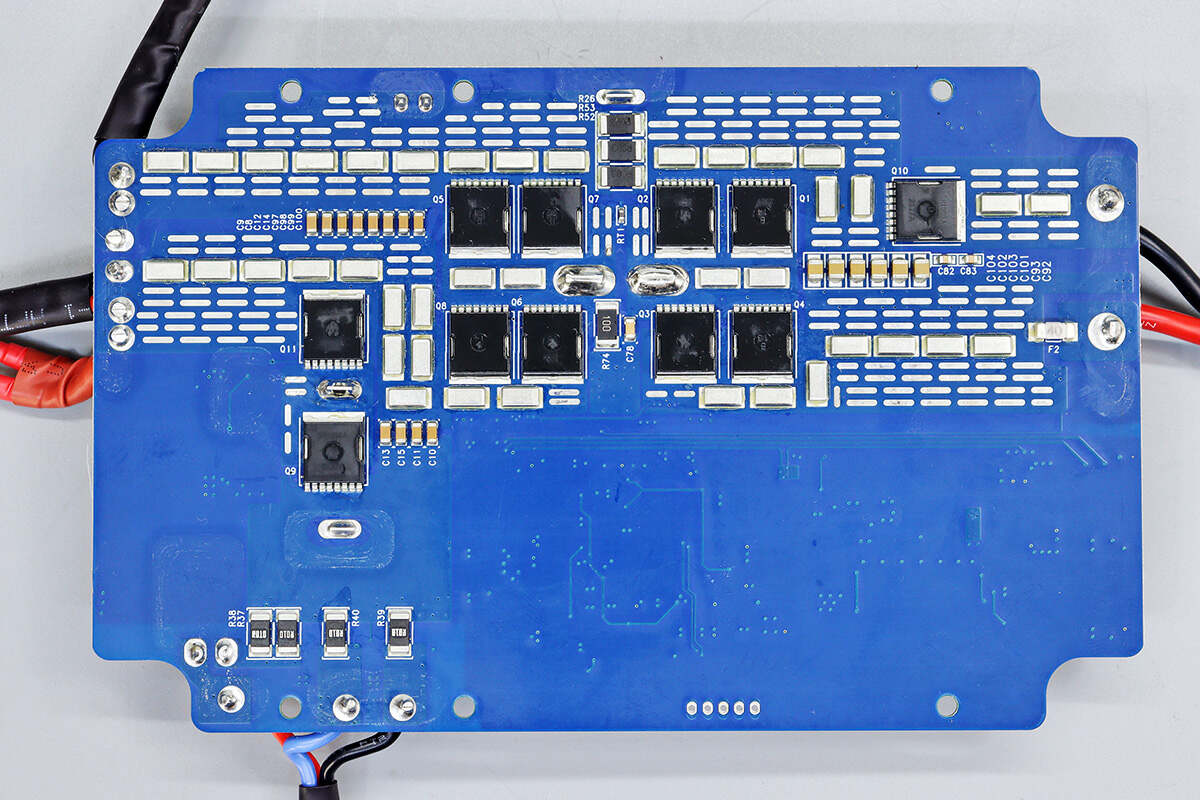

The back of the MPPT module is welded with synchronous boost and buck MOS transistors and buck MOS transistors. The input end is equipped with a fuse for overcurrent protection, and copper blocks are welded to increase the current carrying capacity. Use a 2410 (6.1 * 2.5mm) volume 40A fuse for protection.

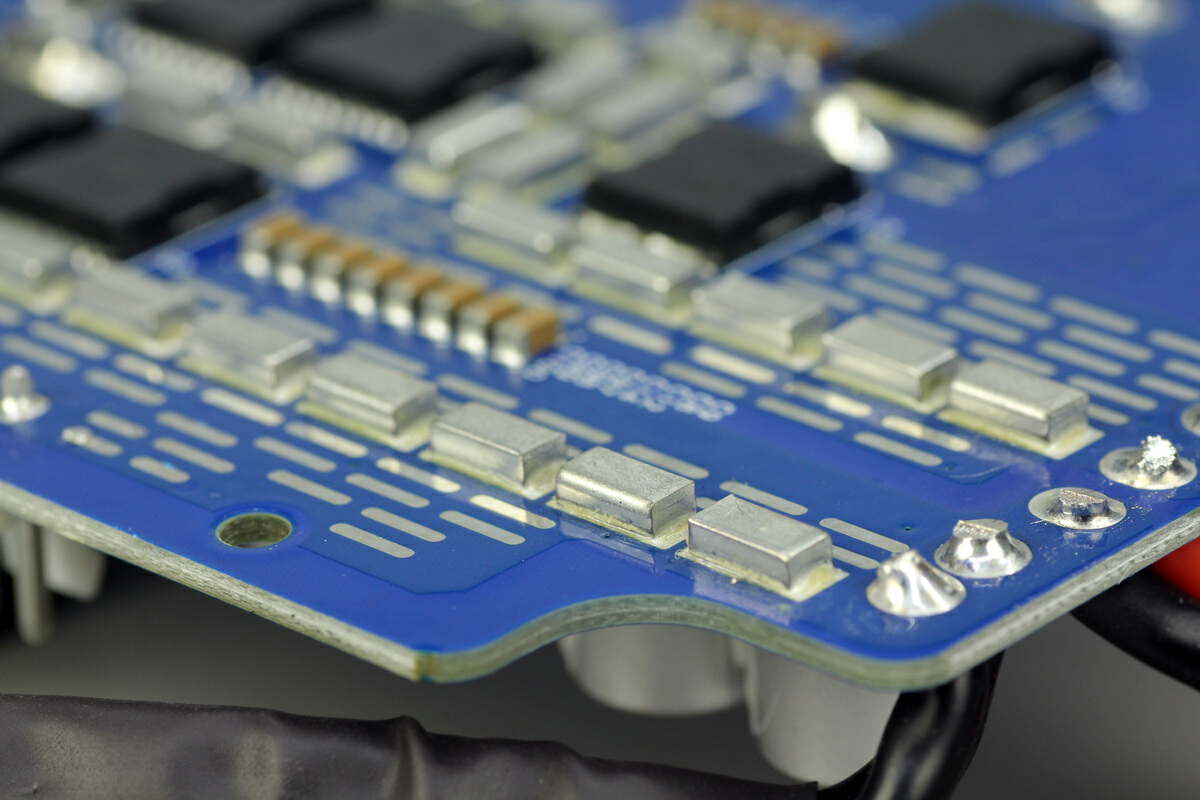

Close up of copper blocks soldered on the back of PCBA modules. Improve current conduction to achieve high power and heat dissipation effect, and use tin plated busbars in large quantities.

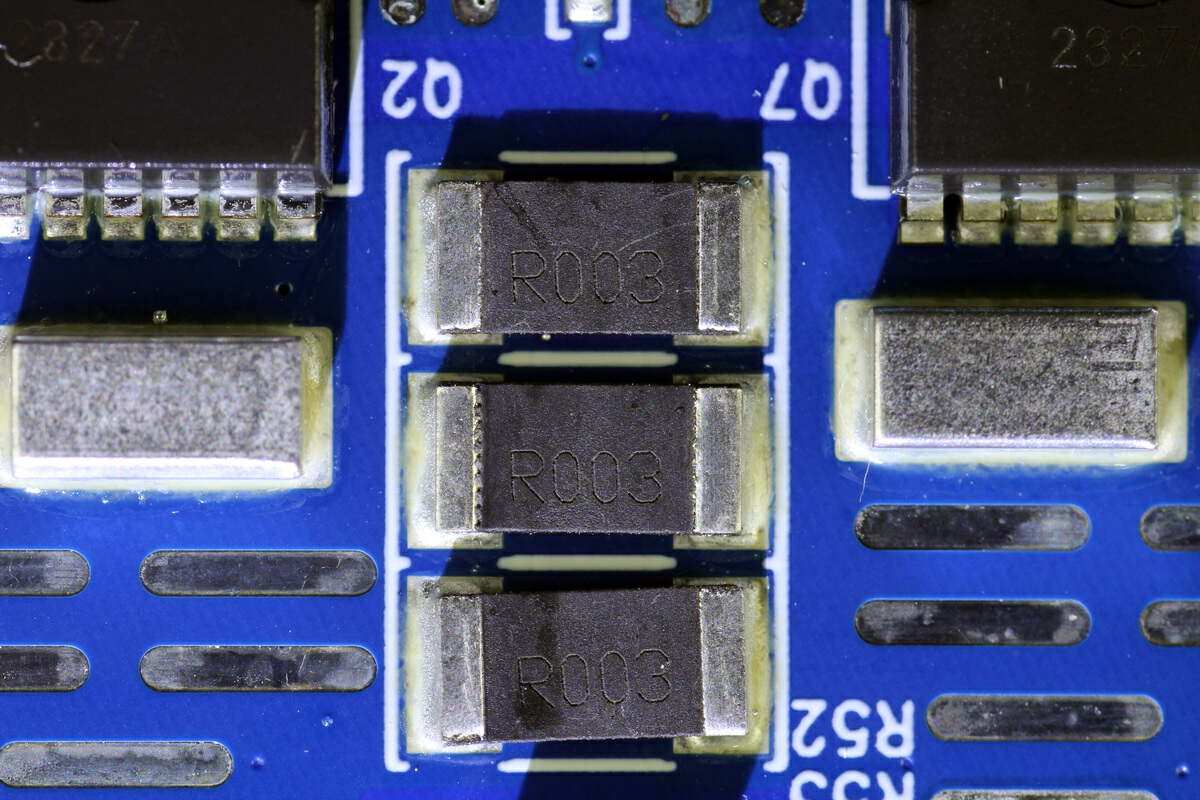

Three 2512 3m Ω sampling resistors are connected in parallel for detecting synchronous voltage rise and fall input and output currents. The recommended model is:EMA25F3W0R003MDG。

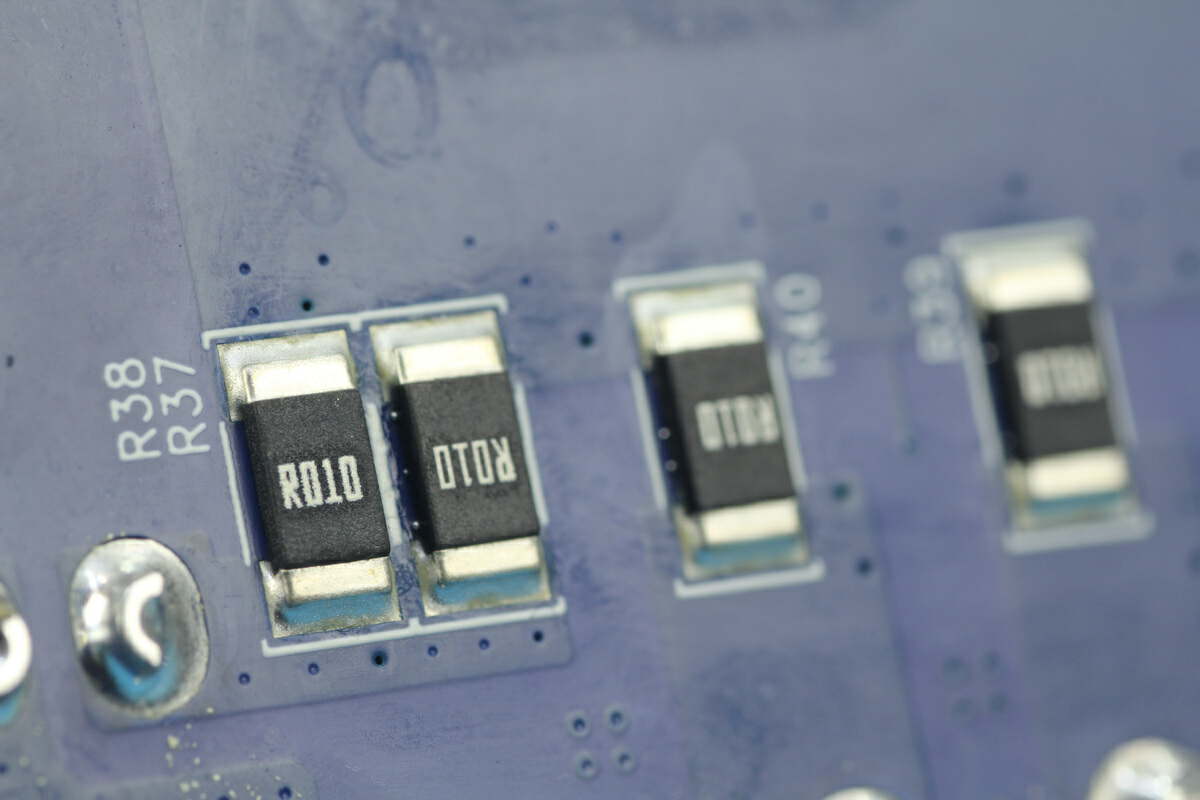

Four 2512 10m Ω sampling resistors are used to detect the step-down output current. The recommended model is:EMA25F3W0R010FDG。

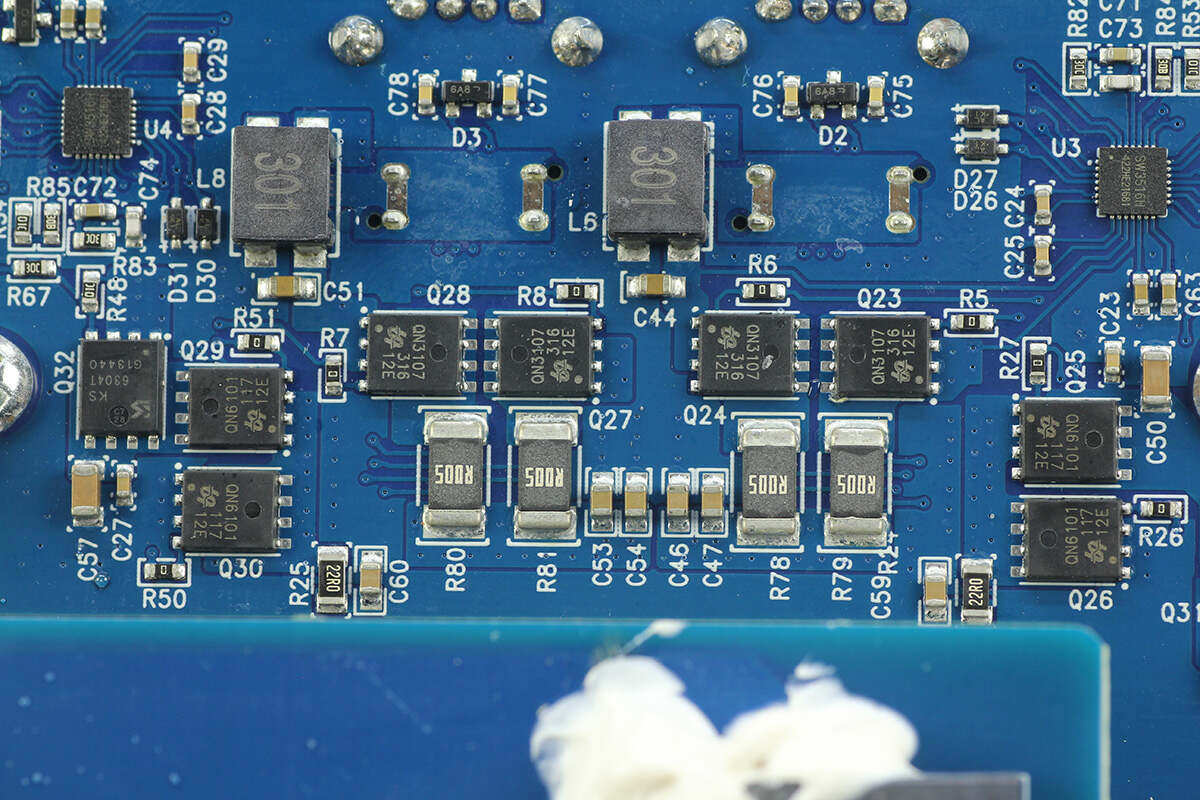

A close-up of the synchronous buck circuit used for fast charging USB-C and USB-A interfaces, saving space by selecting one of them for introduction. It uses four 2512 0.005R (5mR) alloy current detection resistors, and the recommended model is:EMA25F3W0R005MDG。

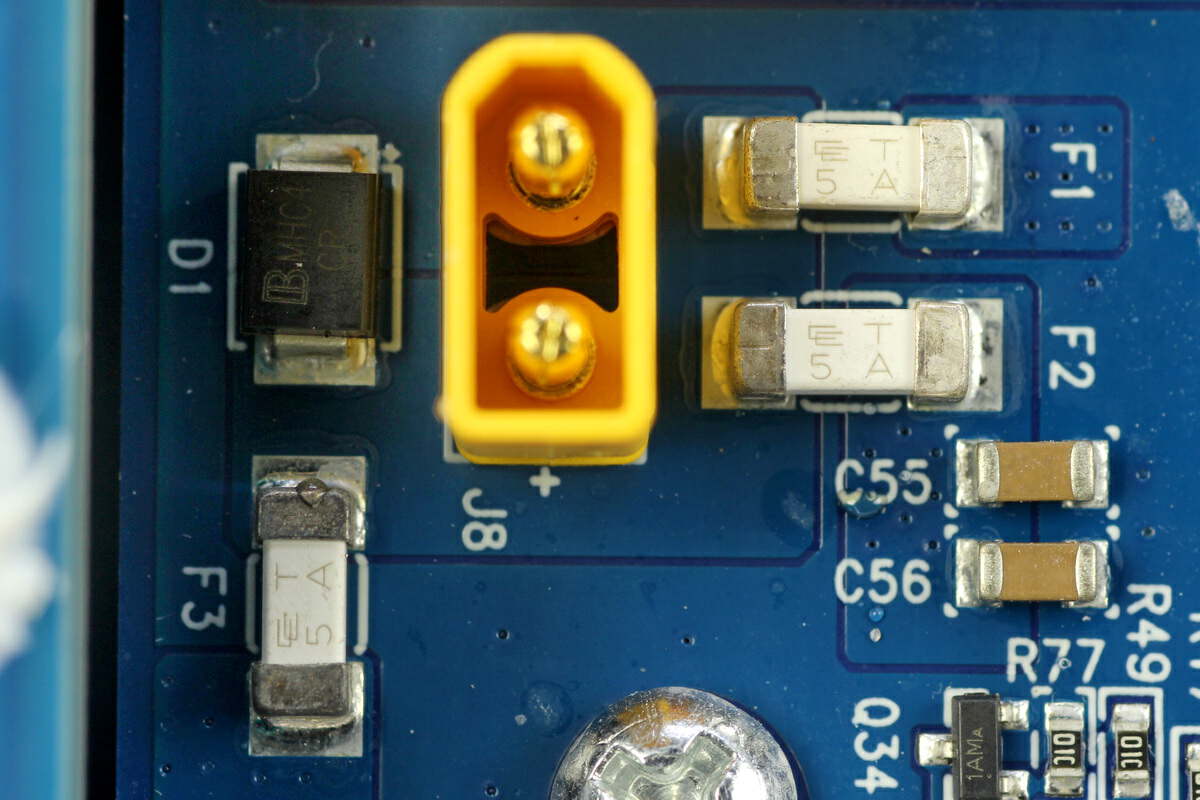

Close up of power input sockets, patch fuses, and TVS. The power input socket uses three 2410T5A250V patch fuses from Chengrun.

Five 2512 1m Ω large solder pad alloy resistors are connected in parallel for detecting the DC terminal current of the inverter. The recommended model is ELLON brand:EMA25F3W0R001MDG。

The input terminal adopts a 20A ceramic tube fuse, recommended model: TSC-T20AH250V ceramic tube fuse, which is from Suzhou Walter Electronics brand.

What specifications of alloy resistors and fuses are needed for a 2000W outdoor power supply from ETAKER Mobile, using a total of EMA25F3W0R001MDG, EMA25F3W0R003MDG,EMA25F3W0R005MDG,EMA25F3W0R04MDG,EMA25F3W0R010MDG, And there are 40A, 25A, and 60A in 2410 volume and 1032 volume, as well as a ceramic tube fuse TSC-T20AH250V