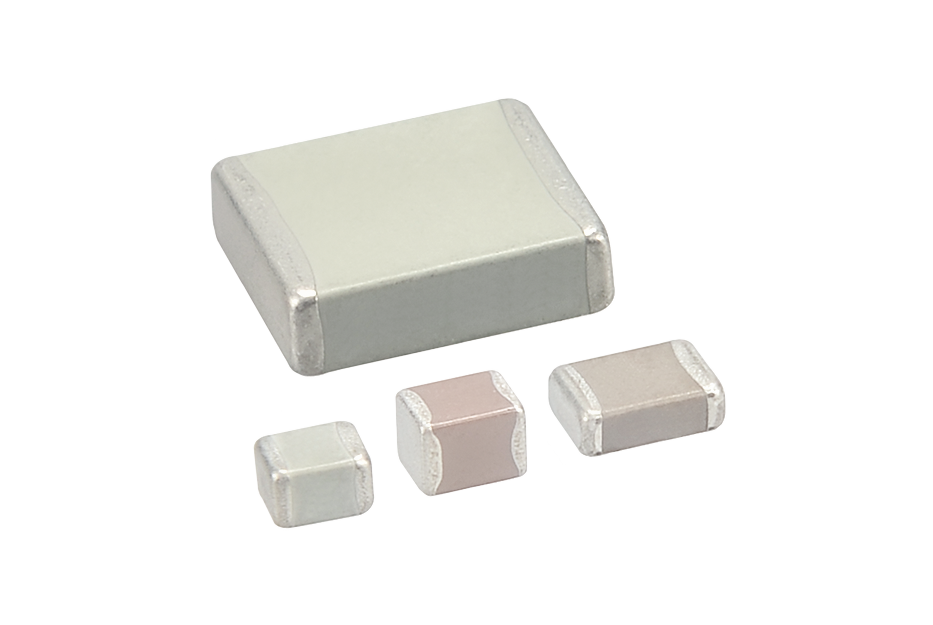

MLCC multilayer hnstshop.com/product-list/C-C-p1.html" target="_blank" rel="noopener">Ceramic capacitor selection list and online purchase address: click the picture to enter

MLCC is the abbreviation of multilayer Ceramic capacitor, which is a common chip capacitor. When choosing MLCC, you often encounter different material choices, such as COG and X7R. The following will provide a detailed introduction to the differences between COG and X7R materials.

COG material COG material is a high-precision ceramic material with very low dielectric loss and linear temperature characteristics. COG capacitors are made by pressing metal electrodes into ceramic chips. COG materials have a high dielectric constant, making them excellent in high-frequency applications. In addition, COG capacitors also have very low dielectric absorption, so they can operate stably at high frequencies. The temperature coefficient of COG material is very low, so it can maintain a stable capacitance value over a wide temperature range. The main characteristics of COG material are small temperature coefficient, good frequency characteristics, but small capacity.

X7R material X7R material is a common ceramic material with medium precision and medium temperature characteristics. The X7R capacitor is made by adding an appropriate amount of additives to the ceramic sheet to change its electrical properties. The X7R material has a high dielectric constant, so it can provide a larger capacitance value in a relatively small size. The temperature coefficient of X7R capacitor is higher than that of COG material, but it can still maintain a relatively stable capacitance value over a wide temperature range. The main characteristics of X7R material are large capacity, moderate temperature coefficient, but poor frequency characteristics.

The difference between COG and X7R (1) Different temperature coefficients: COG materials have very low temperature coefficients and can maintain stable capacitance values over a wide temperature range; The temperature coefficient of X7R material is relatively high, and it can still maintain a relatively stable capacitance value over a wide temperature range, but it is not as stable as COG material. (2) Different frequency characteristics: COG materials have excellent frequency characteristics and can work stably at high frequencies; The frequency characteristics of X7R material are poor and are easily affected by frequency. (3) Different capacity sizes: COG materials have smaller capacity and are suitable for applications that require high-precision and high-frequency characteristics; The X7R material has a large capacity and is suitable for general applications. (4) Price difference: Due to the higher accuracy and better frequency characteristics of COG materials, the price is relatively high; The price of X7R material is relatively low.

In summary, COG and X7R are two common MLCC materials that have significant differences in temperature coefficient, frequency characteristics, capacity size, and price. When choosing MLCC, it is necessary to choose the appropriate material based on the specific application requirements. If high-precision and high-frequency characteristics are required, COG material can be selected; If the temperature and frequency requirements are not so strict, you can choose X7R material. By selecting materials reasonably, it can meet the needs of different applications for MLCC.