Comprehensive analysis of 3921 alloy resistor manufacturer

Introduction to 3921 Alloy Resistors

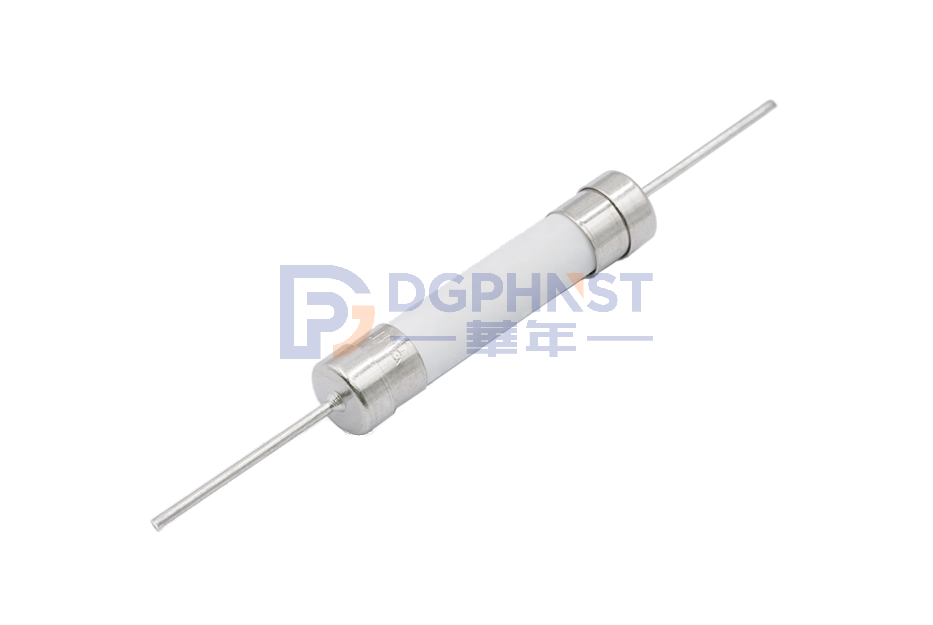

3921 alloy resistor is a high-power, low resistance current detection resistor widely used in the electronics industry. Its external dimensions are 10.0mm × 5.2mm (3921 package). Due to its excellent electrical characteristics and stable performance, this resistor plays an important role in power management, current detection, and control circuits. The 3921 alloy resistor model can provide high power carrying capacity, typically ranging from 3W to 9W, with a resistance accuracy of up to ± 1% and excellent temperature coefficient, enabling it to maintain stable operation in various harsh environments.

Main 3921 alloy resistor manufacturers and product features

Huade Electronics

The STE3921M3W0R020F alloy resistor produced by Huade Electronics is a typical 3921 packaged product with a resistance of 0.02 Ω (20mR), an accuracy of ± 1%, and a rated power of 3W. The product is made of MnCu alloy material, with a temperature coefficient of ± 50PPM and a wide operating temperature range (55 ℃~170 ℃), which meets the requirements of the EU RoHS directive. The structural design of the Huade 3921 alloy resistor is scientific. The substrate is made of alumina ceramic, and the end electrode is a Cu/Ni/Sn three-layer structure, ensuring good welding performance and long-term reliability.

Vishay

Vishay is a globally renowned electronic component manufacturer with a rich and diverse product line of 3921 alloy resistors. Vishay's WSLP39211L000FEB is a high-performance alloy resistor with a resistance as low as 1m Ω, a power of up to 9W, and a working temperature range of 65 ℃ to 170 ℃. The WSLT3921L5000FEA has an ultra-low resistance of 500 µ Ω, a power of 3W, uses metal strip technology, and a temperature coefficient of ± 175ppm/° C, making it particularly suitable for high-precision current detection applications. Vishay's 3921 alloy resistor series complies with AECQ200 standards and is suitable for automotive electronic applications, with ultra-low inductance (<5nH) and low thermoelectric potential characteristics.

Ellon

The ESRH31F8W0M75M02G alloy resistor produced by Ellon adopts metal strip technology, with a resistance value of 0.75m Ω, a power of 8W, and a tolerance of ± 1%. The working temperature range of this product is 55 ℃ to 170 ℃, with dimensions of 10mm × 5.2mm × 0.5mm and a weight of 0.723g. Ellon's 3921 alloy resistor is designed specifically for current sensing applications and performs excellently in power electronic devices.

TT Electronics

The LRMAP3920CR002FT alloy produced by Welwyn brand under TT Electronics has a resistance value of 0.002ohm, a power of 4W, and a tolerance of ± 1%. This product adopts metal alloy technology with a temperature coefficient of ± 50ppm/° C, which meets the AECQ200 automotive standard. The LRMAP3920 series has excellent long-term stability and low inductance characteristics (<3nH), with resistance values ranging from 0.2m ohm to 2mohm, suitable for demanding current sensing applications.

Prosemi

The PSR39K5FR003 produced by Prosemi is an alloy resistor packaged in 3921, with a power of 5W, a resistance of 3m Ω, and an accuracy of ± 1%. This product is made of low resistance alloy material. Although it has been discontinued, its design concept and technical features are still worth learning from.

Summary of Technical Characteristics of 3921 Alloy Resistors

3921 alloy resistor, as a high-power current detection component, has multiple technical advantages:

High power density: achieving a power carrying capacity of up to 9W in a relatively compact package

Low resistance range: The resistance can be as low as 0.0003 Ω, meeting the requirements of precision current detection

Excellent temperature characteristics: The temperature coefficient is usually ± 50PPM to ± 175PPM, and the working temperature range can reach 65 ℃ to 275 ℃

High stability: Alloy materials provide excellent long-term stability and low inductance characteristics

Compliant with environmental standards: Most products comply with the RoHS directive and meet environmental requirements

Suggestions for selecting 3921 alloy resistors

When selecting a 3921 alloy resistor, engineers should consider the following key factors:

Power requirement: Choose products with 3W, 4W, 5W, 8W, or 9W according to the power requirements of the application scenario

Resistance accuracy: For ordinary applications, a tolerance of ± 1% can be selected, while for higher requirements, products with a tolerance of ± 0.5% can be considered

Temperature coefficient: Select products with appropriate temperature coefficients based on the range of temperature changes in the working environment, such as ± 50PPM or ± 175PPM, etc

Certification requirements: Automotive electronic applications must select products that comply with AECQ200 standards

Cost and Supply: Consider the cost-effectiveness and supply cycle of products from different manufacturers

3921 alloy resistors have broad application prospects in fields such as power management, industrial control, automotive electronics, and communication equipment due to their excellent performance characteristics.