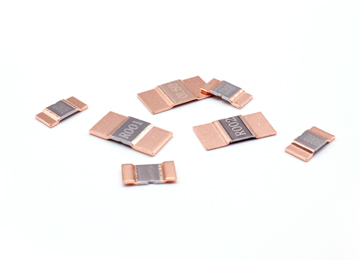

Analyzing the core parameters of 1206 packaged bare copper resistors (recommended for the Ellon ESR series)

In circuit design, bare copper resistors become a crucial choice when dealing with high currents and extremely low resistance values. Among them, 1206 packaging is a common size specification. Understanding the following core parameters is crucial for correctly selecting bare copper resistors packaged in 1206.

1、 Size and packaging parameters

Firstly, the name 1206 directly indicates its packaging size. It represents the length and width dimensions of the component, typically 3.2mm x 1.6mm. This standardized size allows it to be compatible with most modern electronic product mounting processes and facilitates automated production. Understanding its physical dimensions is the first step in PCB layout design.

2、 Electrical performance parameters

This is the core part of selecting bare copper resistors, mainly focusing on the following three points:

Resistance value: This is the most basic parameter. The resistance of bare copper resistors is extremely low, usually measured in milliohms. The resistance range of bare copper resistors packaged in 1206 is generally between 0.5 milliohms and several tens of milliohms. The specific value depends on the alloy composition, thickness, and internal structure of the copper sheet.

Rated power: It represents the maximum power that a resistor can safely dissipate continuously. The bare copper resistors packaged in 1206 typically have a rated power between 1W and 2W due to their volume limitations and material properties. When designing, it is necessary to ensure that the actual power consumption in the circuit is lower than this value and consider leaving some margin.

Rated current: This is a crucial parameter for bare copper resistors. Due to its extremely low resistance, it is often used to carry large currents of several amperes or even tens of amperes. The rated current capacity of the 1206 package will be limited by its own resistance value and heat dissipation design, and it is necessary to carefully consult the product manual.

3、 Material and process parameters

The performance of bare copper resistors is largely determined by their materials and manufacturing processes.

Base material: As the name suggests, its main body is copper or copper alloy. But in order to improve performance, special alloy materials with low temperature coefficient and good stability such as manganese copper and constantan are usually used.

Electrodes and Electroplating: The electrodes at both ends of the resistor are usually subjected to electroplating treatment, commonly tin plating or nickel plating. A good electroplating layer can ensure excellent weldability and prevent oxidation during storage and use, ensuring the reliability of the connection.

4、 Temperature related parameters

Temperature coefficient: It describes the degree to which the resistance value changes with temperature. A good bare copper resistor should have a very low temperature coefficient, which means that the resistance changes very little within its operating temperature range, ensuring measurement accuracy and circuit stability.

summary

When choosing a bare copper resistor with a 1206 package, engineers cannot just look at a single resistance value. It is necessary to comprehensively consider multiple core parameters such as packaging size, rated power, maximum current carrying capacity, material composition, and temperature stability. Only by fully understanding these parameters can we ensure that the selected resistors work stably, reliably, and for a long time in the circuit, especially in high current applications such as power management and current sampling. It is recommended to use the product manual provided by the specific manufacturer as the final basis for actual selection.