Complete Analysis of Tian'er Alloy Resistance Series: Precise Selection Guide

Faced with the demand for high power ranging from 0.3m Ω ultra-low resistance to 15W, Ever Ohms Alloy resistors provide accurate and stable solutions for current detection applications through more than ten series of products in three major categories.

The core material of Tian Er alloy resistor is a special alloy processed by special smelting technology, which has high uniformity and stability. This material not only has excellent conductivity, but also maintains stable resistance values in harsh environments such as high temperature, low temperature, and high humidity.

Tian Er alloy resistors are widely used in scenarios that require high-precision current sampling, such as new energy vehicle BMS, power modules, and motor drives.

01 Product Overview and Core Advantages

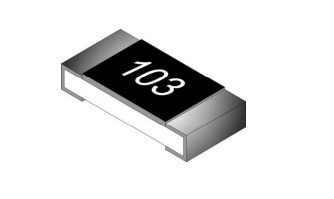

Tian'er Alloy Resistors are chip resistors made of special metal materials, characterized by high power, low resistance, and high reliability.

This type of resistor is mainly used for current sampling and feedback in circuits, and is therefore often referred to as current sampling resistor or current sensing resistor.

Compared to ordinary thick film resistors, Tian Er alloy resistors have a lower temperature coefficient. Its typical temperature coefficient can be controlled between ± 25ppm/℃ and ± 50ppm/℃, while ordinary thick film resistors are usually around ± 100ppm/℃. This characteristic enables the alloy resistor to maintain a stable resistance value even in environments with significant temperature changes.

02 Pure Metal Alloy Resistance Series

The pure metal version alloy resistor is the foundation of Tian'er Alloy resistor product line, made of block alloy material, suitable for most conventional current detection applications.

The MA series is a representative product of this category, covering a variety of packaging sizes from 0805 to 4527. The resistance range is wide, from 0.3m Ω to 0.45 Ω, with a maximum power of 7W.

The MA series offers four accuracy levels of ± 0.5%, ± 1%, ± 2%, and ± 5%, using different materials such as manganese copper tin, manganese copper, or iron chromium aluminum. Among them, products packaged in MA2512 are widely used in power modules and BMS battery management systems.

The MAL series is an optimized version of the MA series, focusing on three packages: 1206, 2512, and 4527. The resistance range is 0.5m Ω to 0.25 Ω, and the power is 1W to 5W. In terms of materials, in addition to manganese copper tin and manganese copper, nickel chromium aluminum options are also added.

The MR series is known for its high cost-effectiveness, mainly offering two packages: 2512 and 2818. The resistance range is 1m Ω to 50m Ω, making it an ideal choice for cost sensitive projects.

For applications with limited space, the MRE series offers small volume packaging options such as 0201, 0402, 0603, etc. These miniature alloy resistors have a resistance range of 1m Ω to 50m Ω and a power of 0.2W to 1W, making them ideal for portable devices and high-density circuit board designs.

The MU series focuses on ultra-low resistance requirements, with a minimum resistance of up to 0.3m Ω. Currently, there are only 2512 packages available, specifically designed for special application scenarios that require extremely low resistance sampling.

03 Metal foil alloy resistor series

Metal foil alloy resistors are manufactured using thin film technology, which has lower parasitic inductance characteristics and is suitable for high-frequency application scenarios.

The MFR series is the core product of this category, with a parasitic inductance of less than 5nH. This feature makes it particularly suitable for power circuits with high switching frequencies.

The MFR series offers a wide range of packaging options, covering standard sizes from 0603 to 4527, as well as special sizes such as 0508, 0612, and 1225. The resistance range is 1m Ω to 560m Ω, and the power is 0.5W to 5W.

This series offers three accuracy levels of 0.5%, ± 1%, and 2%, using manganese copper or copper alloy materials. For example, products packaged in MFR2512 can have a power of up to 2W and a temperature drift of ± 75ppm/℃.

The four terminal version of the MFR series adopts a special pad design, which can effectively eliminate the influence of lead resistance on measurement. This design is particularly important in situations that require high-precision current measurement, such as precision instruments and high-end power management systems.

04 Bare Copper Sheet Metal Diverter Series

The bare copper metal shunt is designed specifically for high-power applications, capable of withstanding larger currents and power.

The SR series is the standard product in this category, with package sizes ranging from 1206 to 5930. The resistance range is 0.2m Ω to 5m Ω, and the maximum power can reach 15W.

This type of resistor is made of manganese copper tin, manganese copper, or iron chromium aluminum materials, providing three precision options of ± 1%, ± 2%, and ± 5%. Large size packaging combined with high power capability makes it an ideal choice for industrial equipment and new energy systems.

The SRF series is a four terminal version of the SR series, featuring special packages such as 1216, 2726, 4026, etc. The resistance range is 0.2m Ω to 3m Ω, and the power is 4W to 7W.

The four terminal design enables the SRF series to achieve more accurate current measurement, making it particularly suitable for applications that require high measurement accuracy, such as high-end testing equipment and precision power systems.

05 Selection Points and Application Matching

When choosing a Tianyi alloy resistor, the following key factors need to be considered:

The resistance range is the primary parameter to consider. Ultra low resistance (less than 1m Ω) is suitable for high current sampling, such as the 0.5m Ω model in the MA series; Medium resistance (1m Ω to 100m Ω) is suitable for most power management and motor control applications.

The power demand directly affects the packaging selection. The 2512 package typically supports 3W power, while the 4527 package provides higher power processing capabilities. At high ambient temperatures, power derating design needs to be considered.

Accuracy requirements determine cost and control effectiveness. The ± 0.5% high-precision model is suitable for precision applications such as battery management systems, while the ± 5% precision model can meet most conventional requirements.

The work environment has special requirements for material selection. Automotive electronic applications require the selection of products certified by AECQ200, while models with sulfur-containing environments require sulfur resistant treatment.

Space constraints determine the packaging size. Portable devices and miniaturized products can consider the MRE series' small volume packaging, while high-power applications require larger packaging to ensure heat dissipation performance.

06 Industry Application and Certification System

Tian'er Alloy Resistors serve multiple high-end industry sectors through a diversified product line.

In the field of automotive electronics, Tian Er alloy resistors are widely used in various sensors, controllers, and actuators. Products certified by AECQ200 can adapt to extreme environments in vehicles, providing guarantees for the safety, comfort, and environmental performance of automobiles.

The new energy system is another important application field, especially in the power management and energy conversion links of solar power generation, wind power generation and other systems. In the BMS battery management system, ultra-low resistance alloy resistors can achieve precise current sampling.

In the field of industrial automation, Tian Er alloy resistors are widely used in various automation equipment such as sensors, transmitters, and actuators. The wide temperature range stability (55 ℃~+170 ℃) and surge resistance enable it to meet the demanding requirements of industrial environments.

In the field of communication equipment, with the development of technologies such as 5G and the Internet of Things, the application of Tian Er alloy resistors in key equipment such as base stations, routers, and switches is also increasing. The MFR series with low parasitic inductance is particularly suitable for high-frequency application scenarios.

Tian'er Technology has passed ISO9001, IATF 16949, TTQS and other certifications in quality management, and complies with the AECQ200 automotive electronics standard. These certifications ensure the reliability and stability of Tian'er Alloy resistor products in high-end applications.

The value of Tian Er alloy resistors is not only reflected in its diverse product line, but also in its stability and accuracy throughout the entire product line.

From the basic applications of the MA series to the high-frequency optimization of the MFR series, and then to the high-power carrying of the SR series, each series has been deeply optimized for specific application scenarios.

These resistor products accurately sample current in BMS battery management system, stabilize power control in motor drive, and ensure signal transmission in communication equipment.

HNST WELCOME! 0755-23173910

English |中文

你当前的浏览器版本过低或不支持。请升级或更换浏览器。推荐浏览器 Chrome Edge。