SiC devices are a new type of silicon-based MOSFET, especially SiC power devices with higher switching speed and wider output frequency. SiC power chips are mainly composed of MOSFETs and PN junctions.

Among numerous semiconductor devices, silicon carbide materials have excellent characteristics such as low thermal conductivity, high breakdown electric field, high electron saturation drift velocity, and high electron mobility. Therefore, silicon carbide semiconductor devices are currently one of the best comprehensive performance semiconductor devices.

Silicon carbide devices have been widely used in the aerospace industry due to their superior electrical properties, but in order to have commercial value, the following key issues must be addressed:

Low on resistance: Silicon carbide field-effect transistors at the same power are about half as small as silicon devices of the same size;

Low noise: Due to the fact that the high-frequency noise of silicon carbide field-effect transistors is two orders of magnitude lower than traditional silicon, they can meet the future requirements for ultra-high resolution and higher frequency with higher resolution and smaller size.

• Ultra high voltage resistance: Under the same conditions, silicon carbide transistors can withstand a higher range of voltage fluctuations;

Efficient heat dissipation design principle: When working at high temperatures or frequencies, silicon carbide field-effect devices have the strongest heat dissipation ability;

Introduction to Silicon Carbide Semiconductor Devices

Silicon carbide (SiC) semiconductor is a third-generation wide bandgap semiconductor material, with a bandgap width of up to 3.18 eV, while the bandgap widths of Si and Ge are 3.4 eV and 2.7 eV, respectively. Therefore, compared to Si material, it has a higher breakdown voltage.

The three materials widely used in power electronic devices, namely silicon, germanium, gallium nitride, and silicon carbide, belong to the first generation of wide bandgap semiconductor materials. Currently, their development is not yet mature, and they have great advantages in applications such as high-frequency power devices and high-voltage high current situations.

With the strong support for photovoltaic power generation under the guidance of national new energy policies and the increasingly obvious advantages of silicon carbide, silicon carbide semiconductor devices have attracted more and more attention from scientific and technological workers and business people.

In the development process of silicon carbide based semiconductor devices, there are still many problems in the process technology that need to be further improved.

This mainly includes: in terms of high temperature and high pressure technology, silicon carbide based transistors will generate significant thermal stress under high temperature and high pressure conditions;

The problem of low-temperature insulation is mainly due to the complex relationship between electron mobility and temperature;

To address these issues, the industry has developed multiple related technologies and products.

1、 Voltage resistance

Silicon carbide based semiconductor devices are high-frequency switching devices with operating voltages between 25~500V, therefore requiring high requirements in terms of voltage resistance.

With the development of power semiconductor devices, traditional Si MOSFETs have gradually been replaced by silicon carbide (SiC) MOSFETs. Due to the higher voltage resistance of SiC based MOSFETs, SiC based power semiconductor devices have become the mainstream solution for high-voltage and high-frequency switching devices.

Silicon carbide semiconductor is an ideal wide bandgap semiconductor material with excellent high-temperature performance and thermal stability, as well as high voltage resistance, high temperature resistance, and high thermal conductivity. Therefore, it is widely used in fields such as high-voltage switches, high-power power supplies, and power electronic devices.

Silicon carbide semiconductor devices have high voltage resistance because they can achieve high electron mobility at high temperatures, effectively reduce heat loss and improve conversion efficiency at high frequencies.

Due to the high thermal conductivity and wide bandgap characteristics of SiC, achieving high conversion efficiency under high voltage will become an important development direction for SiC based MOS power semiconductor devices.

2、 Leakage current

SiC has a high thermal conductivity, which can reduce the thermal resistance of the device. As the frequency increases, its thermal resistance will rise. However, this does not mean that SiC does not require a cooling system. Without a special cooling system, SiC can also operate in higher frequency environments

(4) The use of metal contact technology can also reduce thermal resistance, but it will increase device power consumption.

Silicon carbide has excellent high-frequency characteristics, with a working frequency exceeding 100 kHz. At present, metal oxide semiconductor field-effect transistors (MOSFETs) or field-effect transistors (FETs) are mainly used to achieve low loss and high voltage resistance.

3、 Switching speed

Compared with Si devices, silicon carbide based transistors have higher breakdown voltage and specific power.

The conduction voltage of SiC based field-effect transistors is lower than that of Si based field-effect transistors, but the switching speed is faster, reaching up to 200 ns.

Compared with SiC based semiconductor devices, SiC has lower thermal performance (especially switching performance) and electrical performance, so the requirements for thermal cycling are not high.

This is particularly important for silicon carbide devices operating at high temperatures and pressures.

In order to improve the high-temperature and high-pressure resistance of the device, various methods can be used.

1. Use single crystal materials with good corrosion resistance, heat resistance, and insulation properties;

2. By optimizing the doping process, the conductivity can be improved; 3. Changing the doping concentration can increase the breakdown voltage of the device; 4. Adjust the doping concentration of SiC to meet the requirements for high temperature and voltage resistance in different current levels.

4、 Working temperature

At present, the operating temperature of silicon carbide based devices is mainly concentrated between 600 ℃ and 1200 ℃.

Although silicon carbide has the characteristic of high temperature resistance, its device performance may also decrease to a certain extent at high temperatures.

Therefore, the stability of silicon carbide based devices in high-temperature environments still needs further research, especially heat-resistant devices.

(2) Under high temperature conditions, thermal resistance is easily generated on the surface of the device.

Silicon carbide based thin-film transistors can achieve high power density packaging over a wide temperature range.

But below 600 ℃, the insulation performance of the device will decrease, and protective circuits need to be added to reduce the insulation temperature; But as the doping concentration in the material decreases, the structural changes of the material are relatively small; At the same time, silicon carbide based transistors can achieve a low-temperature cut-off voltage below 2 eV.

Due to its high voltage and heat resistance, as well as high temperature resistance, silicon carbide based products have been widely used in high-voltage and high-frequency fields such as power amplifiers.

5、 Switching frequency and dynamic range

Due to the higher breakdown voltage and thermal conductivity of silicon carbide based semiconductor devices, silicon carbide electronic devices can withstand higher operating frequencies and reduce the impact of thermal stress on their reliability when applied under high-frequency and high-temperature conditions.

Silicon carbide based semiconductor devices have fast switching speeds and do not experience signal jitter due to low dynamic range in high-frequency applications.

By adopting different technological methods, the performance of silicon carbide semiconductor devices can be effectively improved under high-frequency, high-voltage, and high current conditions.

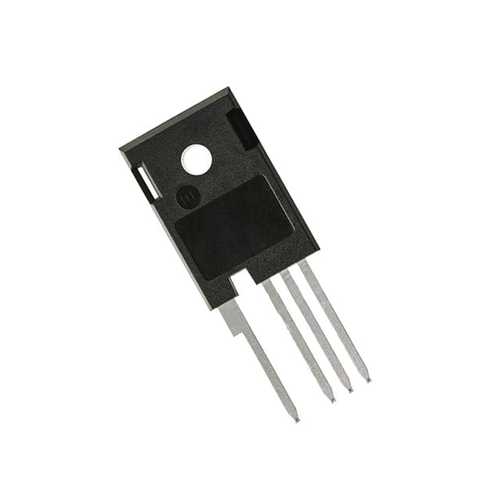

At present, various packaging forms of silicon carbide semiconductor devices have been developed in the industry, and the performance of silicon carbide devices under high temperature and high pressure conditions has been studied through simulation and testing.

Among them, a stacked structure composed of SiC ceramic substrates (such as Baseline, NCVD, etc.) and silicon carbide matrix materials (such as Incoloy-N and Si0 Bi) is used to encapsulate SiC stacked electrodes on the substrate and form a conformal structure with it. This packaging structure can effectively reduce the thermal expansion coefficient of the device itself, enabling silicon carbide transistors to have higher switching frequencies.

6、 Reverse recovery time

Reverse recovery time refers to the transition time of semiconductor devices from zero drift to near zero drift during reverse bias.

The reverse recovery time depends on the material and process, and currently the most commonly used is the reverse recovery time of SiC MOSFET. The shorter the reverse recovery time, the larger the current capacity.

In general, when the highest temperature of a diode during operation is higher than the critical temperature (or breakdown temperature), semiconductor devices will generate significant thermal stress, leading to device failure. Therefore, it is necessary to predict the maximum temperature and critical temperature during device operation.

At present, there is a method used in the industry to predict the reverse recovery time of devices: a series of parameters are used to compare the forward recovery time and reversibility required for the device to break down under different operating conditions, in order to achieve reverse recovery time prediction.

7、 Size and cost issues

The size of silicon carbide devices has a significant impact on cost. Based on the current technological level of SiC device products, their cost may be 30% to 50% lower than silicon devices, but in the long run, as the size increases, their cost will further increase.

If silicon carbide power transistors and diodes are made using devices of the same size at the same process level, the required equipment investment and material costs are relatively high. Because using power transistors of the same size but different materials (such as IGBT) can achieve the same power output capability.

Currently, there are some companies on the market that use silicon carbide for production:

However, due to the fact that silicon carbide based semiconductor materials are prone to thermal stress at high temperatures and pressures, the production process using silicon carbide is complex and costly.

At present, only a few domestic enterprises are able to independently design and produce silicon carbide based power tubes and diodes.