This article introduces the short-circuit capability of 1200 V SiC MOSFET and the overcurrent protection solution using ready-made driver ICs. Several design considerations were discussed to ensure accurate measurements. The test results indicate that the short-circuit capability of SiC MOSFET is highly correlated with the drain voltage and gate voltage, but not sensitive to the shell temperature and switching speed. By reducing the gate drive voltage or reducing the bus voltage, a longer endurance time can be achieved, but these solutions will lower the performance of SiC MOSFETs.

A better solution is to implement overcurrent protection to detect device overcurrent and safely shut down the device. Commercial IGBT drivers with desaturation protection can effectively protect SiC MOSFETs, but circuit optimization is needed to ensure that the total response time of desaturation protection is short enough to protect SiC MOSFETs. We compared the performance of various ready-made gate driver ICs with desaturation protection function and demonstrated a gate driver design that can protect 1200V SiC MOSFET under real short-circuit conditions.

Due to its extremely low switching losses, silicon carbide (SiC) MOSFETs provide broad prospects for maximizing the efficiency of power converters. However, their short-circuit robustness has long been a topic of discussion when determining whether these devices are practical solutions for actual power conversion applications.

Due to its relatively small chip size, higher short-circuit current density, and smaller heat capacity, SiC MOSFETs have a shorter short-circuit withstand time than similarly rated silicon IGBTs. Fortunately, a recent study on 1200 V, 80 m Ω SiC MOSFETs has shown that a correct gate drive design that supports faster response time can protect SiC MOSFETs from short circuit damage. This study will discuss the short-circuit capability of 1200 V, 80 m Ω SiC MOSFET. Presented and explained the results of destructive testing collected under various operating conditions, as well as design trade-offs from the perspectives of applications and devices. In addition, another part of this study compared the performance of various ready-made gate driver ICs with desaturation protection function.,

SiC MOSFET structure and short-circuit capability

When comparing Si IGBT and SiC MOSFET with similar rated currents, SiC MOSFET has a current density 5-10 times higher under short-circuit conditions. Higher instantaneous power density and smaller heat capacity result in faster temperature rise and lower short-circuit withstand time. The saturation current of MOSFET is mainly controlled by the design of the channel region. Although shorter channels and higher on gate voltages are desirable for reducing on resistance, they also increase saturation current and reduce short-circuit withstand time. The trade-off between on resistance and short-circuit current is inherent in SiC MOSFET design and is best addressed by designing gate drives with faster response times than traditional IGBT gate drives.

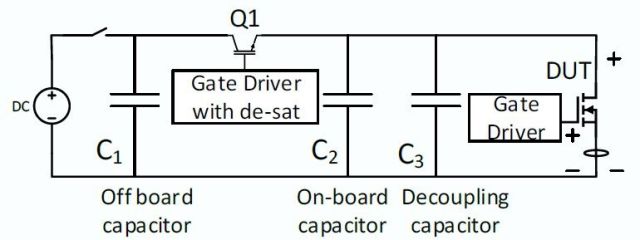

Figure 1a: Schematic diagram of short-circuit test circuit.

Destructive short circuit test results

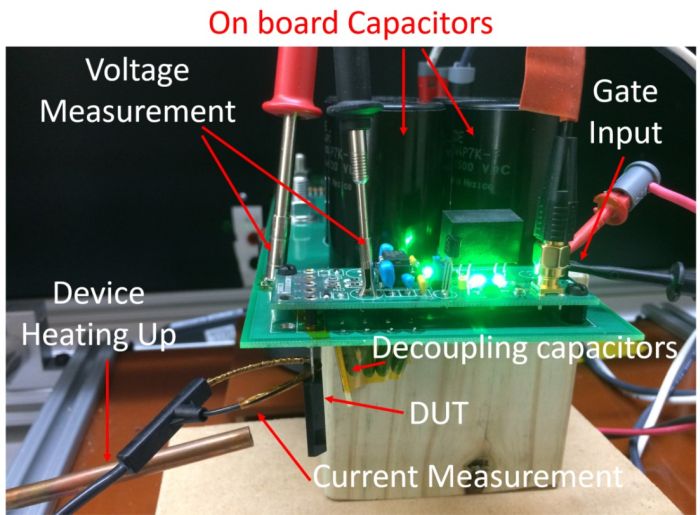

The test circuit (Figures 1a and 1b) aims to evaluate the short-circuit capability of a 1200 V, 80 m Ω SiC MOSFET (Littelfuse LSIC1MO120E0080) (Figure 2) under various operating conditions. High bandwidth, high-voltage passive probes are used to measure the drain source (V DS) and gate source (V GS) voltages; Rogowski coils are used for measuring device current (I DS).

图 1b:Short circuit test setup. An acrylic shell surrounds the testing device to protect the equipment and experimenters in the event of catastrophic equipment failure/explosion.

图 1b:Short circuit test setup. An acrylic shell surrounds the testing device to protect the equipment and experimenters in the event of catastrophic equipment failure/explosion.

Figure 2: The tested device in this evaluation is Littelfuse LSIC1MO120E0080 series enhanced 1200 V, 80 mOhm N-channel SiC MOSFET

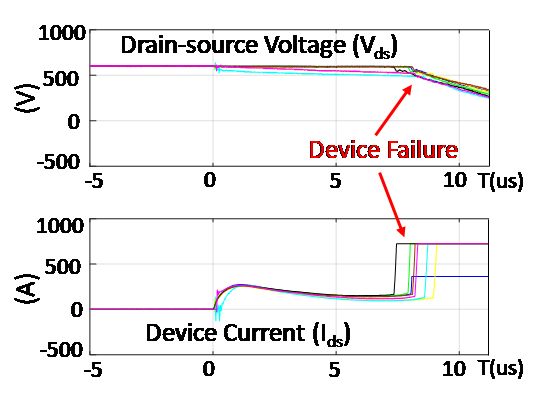

Figure 3 shows the short-circuit test results of 10 samples at room temperature with a drain voltage of 600 V and a gate voltage of 20 V. Figures 4 and 5 show the short-circuit withstand time and critical energy results for destructive faults. The result distribution of the devices is tight, with a short-circuit current of about 250 A, and the short-circuit withstand time of all devices is greater than 7 µ s.

Figure 3: Short circuit test results of different devices

Figure 4: Withstand time at 600 V DC drain voltage

Figure 5: Critical energy at 600 V DC drain voltage

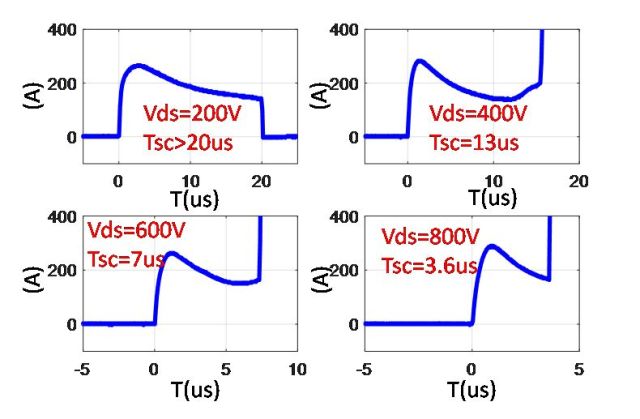

Figure 6 shows the short-circuit test results under various drain voltages ranging from 200V to 800V at a gate voltage of 20V. Although the peak current is similar, the short-circuit withstand time is around 250A under all conditions, ranging from 20 to 200 V drain voltage in µ s and 800 V in 3.6 µ s. As the DC bus voltage increases, the instantaneous power consumption also significantly increases. Therefore, the temperature rise is faster, resulting in a lower short-circuit withstand time.

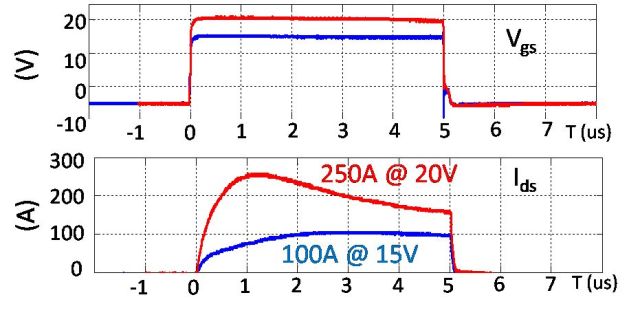

Figure 7 shows the test results with gate voltages of 15 V and 20 V and drain voltage of 600 V. These results indicate that the peak current strongly depends on the gate voltage, decreasing from 250 A at 20 V gate voltage to 100 A at 15 V gate voltage, supporting the design trade-off theory. The relationship between driving voltage/on resistance/short-circuit peak current and withstand time has been discussed earlier in this article. The other factors that have been studied but proven to have no significant effect on the short-circuit withstand time of the device are the external gate resistance of the device and the ambient temperature.

Figure 6: Short circuit under different DC drain voltages

Figure 7: Short circuit under different gate driving voltages

Short circuit protection through gate driver IC desaturation protection

Protecting SiC MOSFETs from short-circuit faults requires the gate driver to detect overcurrent conditions and turn off the MOSFET within its withstand time. Several ready-made driver ICs developed for Si IGBT devices provide integrated de sat protection function, which can monitor V DS during conduction state and shut down the device in case of overcurrent events. If the response speed of the driver IC is fast enough, the same driver IC can be used for short-circuit protection of SiC MOSFET.

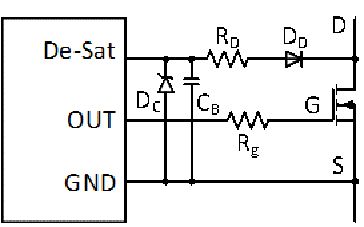

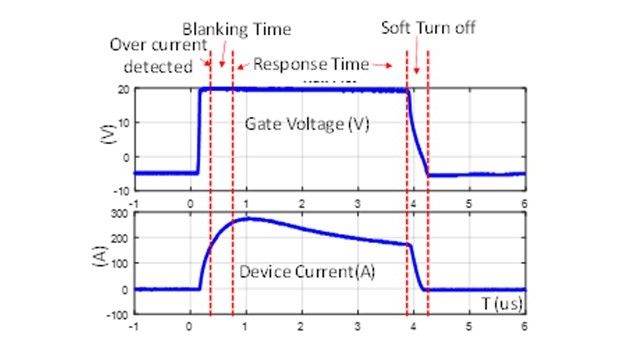

Figure 8 shows the circuit used to achieve desaturation function through various driver ICs. The fast acting Si diode (D D) prevents V DS in the off state, the Zener diode (D C) protects the de sat pin during switching, and the capacitor (C B) controls the blanking time to avoid false triggering during switching transients. Figure 9 shows the waveform of a short-circuit event with a desaturation protection enabled IC. Due to the fast switching speed and required optimized power circuit layout of SiC MOSFETs, the time required for device voltage and current to reach steady state after transient events is much shorter than that of IGBTs. Therefore, the blanking time required for the desaturation function of driver ICs used in SiC based designs should also be shorter. In order to protect SiC MOSFETs, it is common to choose CB with a capacitance less than 100 pF and a blanking time as short as 200 ns to reduce the total response time of the driver IC.

Figure 8: Implementation of Desaturation

Figure 9: Desaturation protection transient

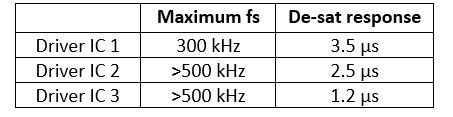

Table 1 compares the performance of different driver ICs with 33 pF blanking capacitors. The results indicate that each IC can protect SiC MOSFET during breakdown within 1-4 µ s. Each of them also has a "soft turn off" function, which can slowly turn off the device under short-circuit conditions to protect MOSFETs and driver ICs.

Table 1: Evaluation of Commercial Driver ICs

Short circuit protection in half bridge configuration

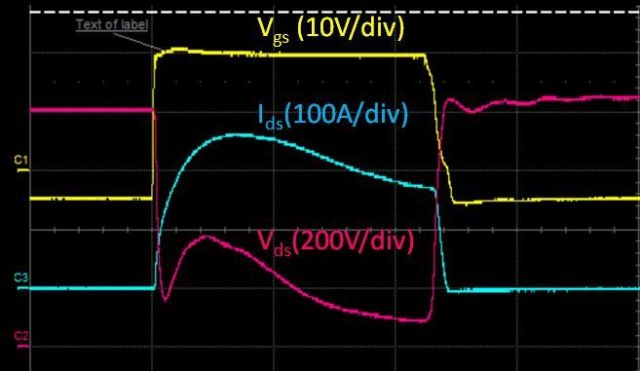

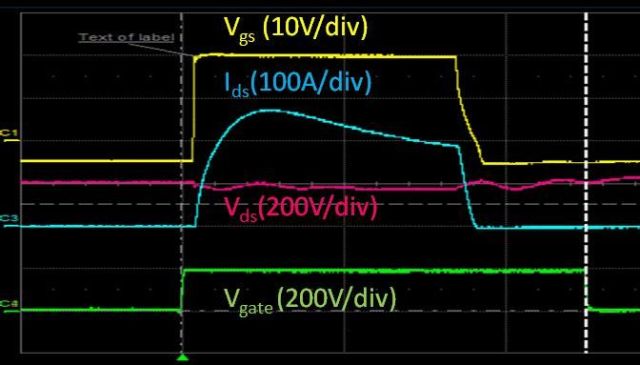

Finally, the SiC MOSFET and gate driver IC with the longest response time were tested together under short-circuit conditions in both single device and half bridge configurations. Figures 9a and 9b show the test waveforms during breakdown transients with a bus voltage of 800 V DC. In the half bridge configuration, the top device remains on throughout the transient period, while the bottom device is driven by a gate driver with desaturation function.

Figure 10a: Breakdown protection of a single device

Figure 10b: Breakdown protection in half bridge configuration

The results in Figure 10 indicate that SiC MOSFET can be safely turned off in both cases. The results also indicate that in the half bridge configuration, the DC bus voltage is shared by two devices, and the actual voltage of each device is much lower than the DC bus voltage, providing more margin for the response time of the protection circuit. If both the bottom and top devices have breakdown protection, then any device can protect the entire circuit.