List of Model Selection and Online Purchase for Thick Film Chip Resistors: Click on the image to enter

hnstshop.com/product-list/C-R-p1.html" target="_blank" rel="noopener">

Thick film patch resistors are a common electronic component widely used in various circuits. It has the advantages of simple structure, small size, high power, and good stability, so it has been widely used in the electronics industry. This article will introduce the characteristics and market performance of thick film patch resistors from the perspective of structural construction.

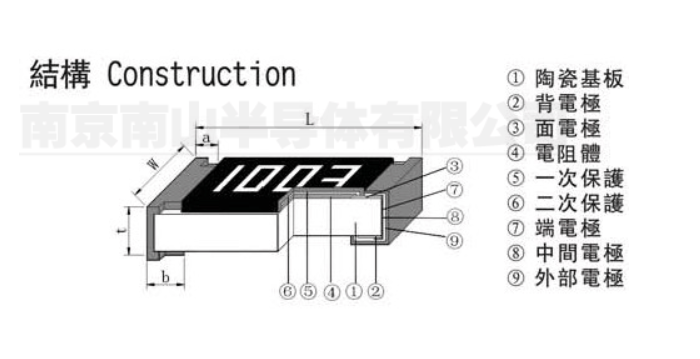

The structure diagram of thick film patch resistors is as follows:

The structural construction of thick film patch resistors mainly includes three aspects: resistance materials, electrode materials, and packaging materials. Firstly, there is the resistance material. The resistance layer of thick film patch resistors is mainly composed of metal materials, such as platinum, silver, copper, etc. These metal materials have low resistivity and good conductivity, which can effectively improve the effect of resistance. Next is the electrode material, which mainly serves to connect the resistance layer with the circuit. Commonly used materials include gold, silver, copper, etc. Different electrode materials have a certain impact on the performance of resistors, and selecting appropriate electrode materials can improve the reliability and stability of resistors. Finally, there is the packaging material, which is mainly used to protect the resistance layer and electrodes. Commonly used packaging materials include resin, porcelain, etc. Packaging materials need to have good insulation and high temperature resistance to ensure the long-term stable operation of resistors.

The structural construction of thick film patch resistors determines their many advantages. Firstly, it has a small size and diverse size specifications, which can meet the space requirements of different circuits. Secondly, it has high power, and thick film patch resistors have high power carrying capacity, which can work stably in high current and high power environments. Once again, it has good stability. The resistance value of thick film patch resistors has high stability and is not easily affected by environmental factors such as temperature and humidity. Finally, the packaging material for thick film SMT resistors has high reliability and can effectively protect the resistance layer and electrodes, extending the lifespan of the resistors.

Thick film patch resistors have performed well in the market, mainly reflected in the following aspects. Firstly, thick film patch resistors are widely used in various electronic devices and circuits, such as computers, communication equipment, automotive electronics, etc. Secondly, the supply is stable. There are many manufacturers in the market that produce and supply thick film patch resistors, which can meet the needs of different customers. Once again, the price is reasonable, and the price of thick film patch resistors is relatively low, with a high cost-effectiveness. Finally, the quality is reliable, and the production process of thick film patch resistors is mature, with stable and reliable quality, which can meet high requirements for electronic equipment manufacturing.

Overall, thick film patch resistors have the advantages of simple structure, small size, high power, and good stability, and are widely used in various electronic devices and circuits. Its structural structure mainly includes three aspects: resistance materials, electrode materials, and packaging materials. The market performance of thick film patch resistors is good, with wide applications, stable supply, reasonable prices, and reliable quality. With the continuous development of the electronics industry, thick film patch resistors will continue to play an important role in providing support for the stable operation of electronic devices.