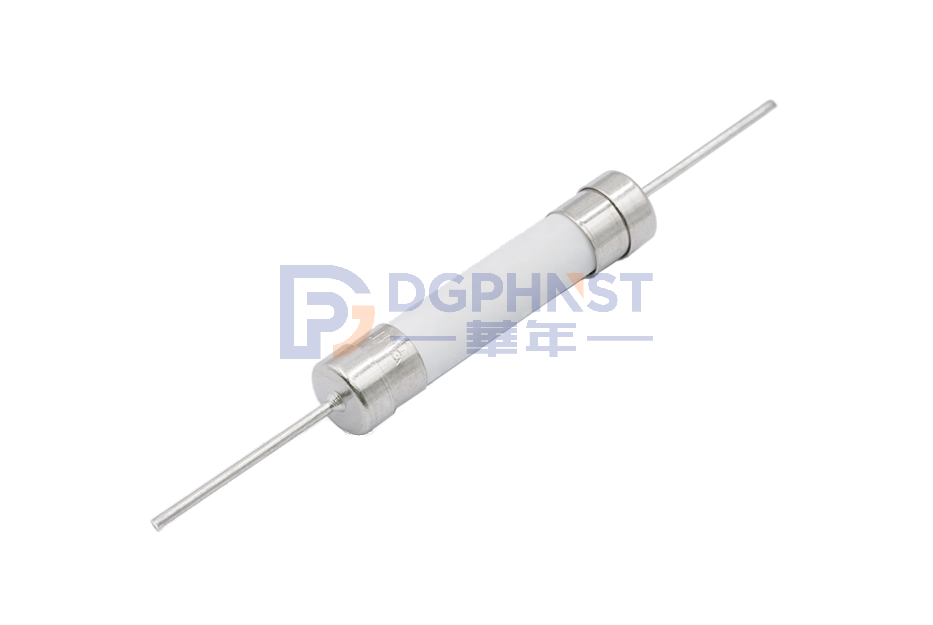

With the continuous progress of technology, current detection technology is applied in various fields. As an advanced research and development company for current detection resistors, Huade Electronics has obvious advantages in the accuracy and stability of current detection. This article will focus on exploring the quality control and standardization of the Huade hnstshop.com/product-list/R07-p1-l10.html" target="_blank">wide electrode current detection resistor MHTC/HTE-M 0508 series products.

In terms of raw materials, the raw materials of the Huade Wide Electrode Current Detection Resistance MHTC/M0508 series products comply with relevant standards and ensure their stable and reliable performance. The procurement, inspection, and storage of raw materials should be strictly controlled to ensure the quality of the raw materials. During the production process, strict adherence to process regulations should be followed to ensure that each production process meets quality requirements. Key parameters during the production process should be monitored and recorded to ensure consistency in product quality. During finished product inspection, strict inspection should be carried out according to relevant standards, including appearance inspection, performance testing, etc. For non-conforming products, traceability and handling should be carried out to prevent them from entering the market.

Huade Company has a comprehensive quality management system, which clarifies the responsibilities of each department to ensure the comprehensiveness and effectiveness of product quality control. At the same time, regular review and improvement of the quality management system are carried out to improve the level of quality management. The Huade wide electrode current detection resistor MHTC/HTE-M 0508 series products comply with relevant national and industry standards, ensuring the universality and interchangeability of the products.

Huade Company has a comprehensive testing standard system, including raw material testing, production process testing, finished product testing, etc. The formulation of testing standards should fully consider the requirements of product performance, safety, environmental protection, etc., to ensure comprehensive guarantee of product quality. Standardized management, standardized workflow and responsibility system should be carried out, and standardized work should be inspected and evaluated regularly to timely discover and solve problems, Promote the deepening of standardization work, cultivate employee standardization awareness, improve employee awareness and understanding of standardization, and through training and practice, enable employees to master standardization knowledge and skills, providing strong support for enterprise standardization work.