What are the requirements for the size of 2512 alloy resistance pads? Considerations behind the design and procurement guidelines

When you carefully observe the large-sized 2512 alloy resistors on the circuit board, you will notice an interesting phenomenon: some resistors have significantly larger solder pads, while others are relatively smaller. This is not a random arrangement in manufacturing, but an important design in precision current detection technology.

When handling current detection tasks with resistance values of several milliohms or even lower, each small change in resistance can lead to significant measurement errors. In the detection system, the resistance of solder may account for a significant proportion of the total resistance of the detection components, seriously affecting the accuracy of the final measurement results.

This explains why the pad design of 2512 encapsulated alloy resistors has become crucial in the field of precision measurement - the design difference between large and small pads directly affects the symmetry of the current path, heat dissipation capacity, and measurement accuracy.

The core reason for the difference in 01 solder pads

The consideration of measurement accuracy is the primary factor in designing different pad sizes. In high-precision current measurement, even small solder resistance can bring significant errors that cannot be ignored.

To reduce these errors, engineers have designed Kelvin detection technology, which achieves more accurate measurements by providing independent paths for system current and detection current.

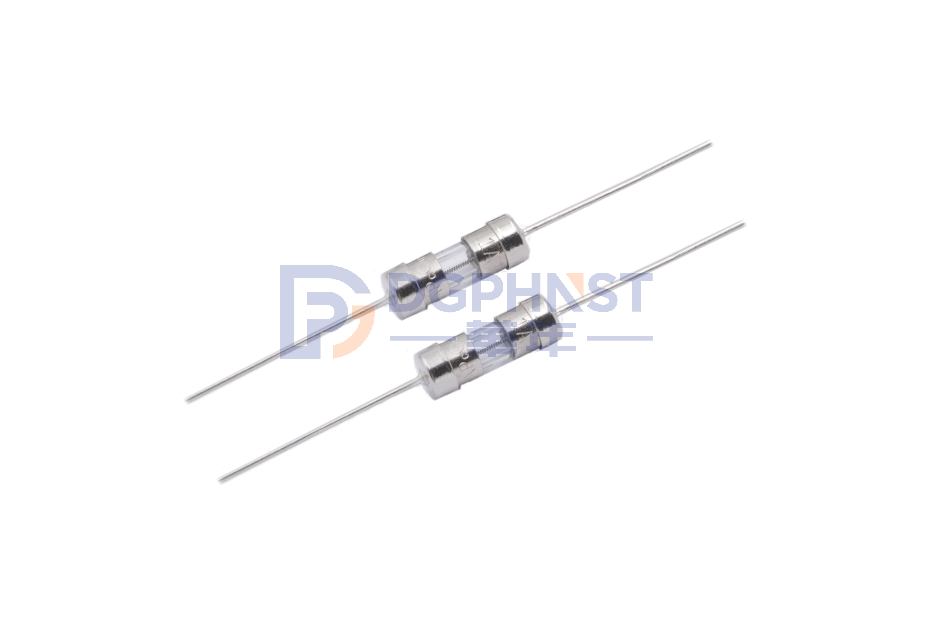

In practical applications, Kelvin detection typically requires four solder joints: two for conducting the main current (usually using larger solder pads), and the other two for voltage detection (smaller solder pads may be used). This separation design can significantly reduce the impact of solder joint resistance on measurement results.

The optimization of current path is also an important consideration in pad design. Optimized pad designs, especially those that provide more symmetrical system current paths on both sides of the pad, can minimize measurement errors.

Research has shown that carefully designed pad layouts can control measurement errors below 1%, which is of great significance in high current detection scenarios.

Design considerations for 02 pad size

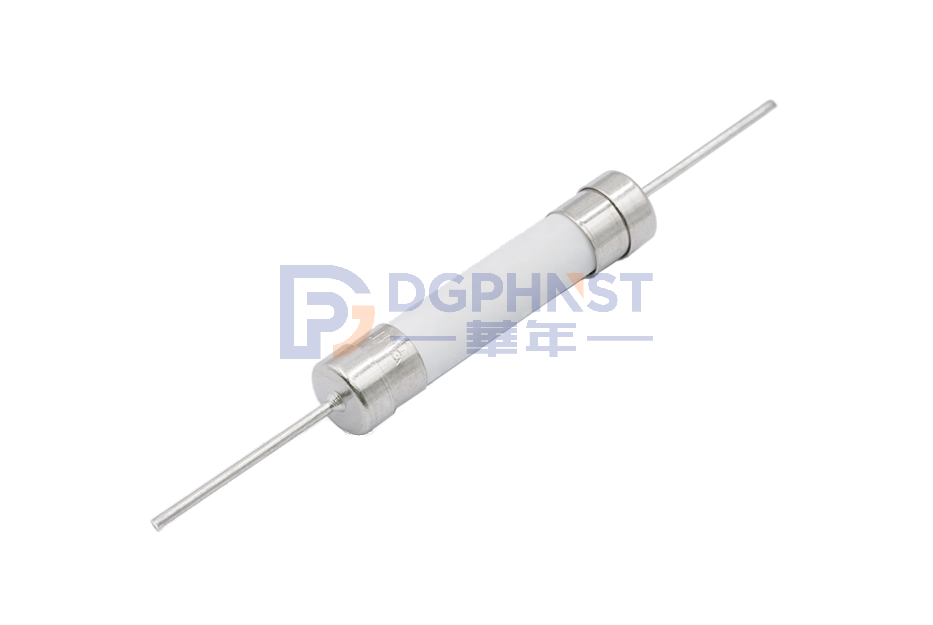

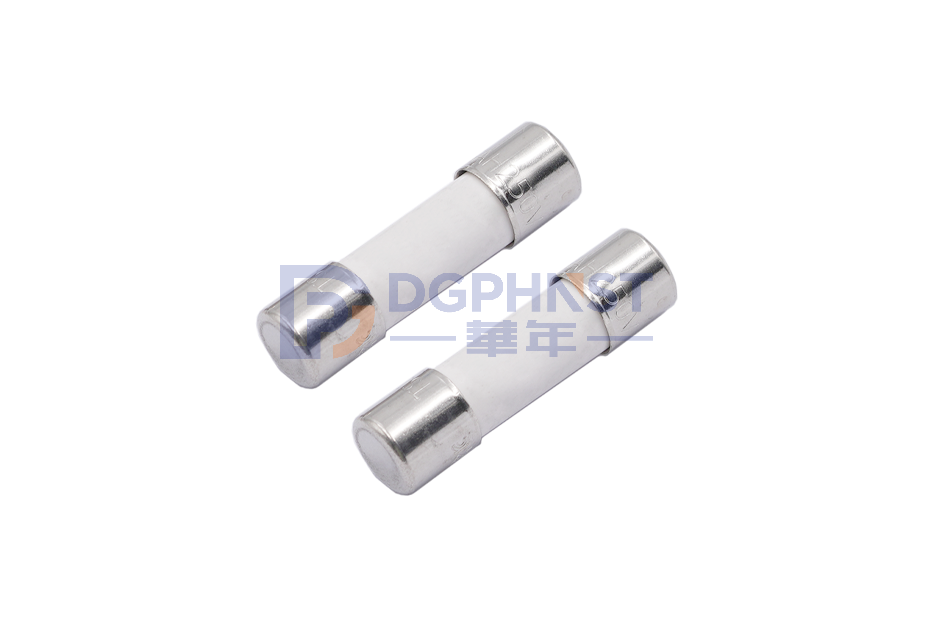

Heat dissipation and power carrying capacity are another key factor affecting the design of 2512 alloy resistance pads. As a medium to large-sized surface mount component, the 2512 package has a size of approximately 3.10mm × 6.30mm, and its relatively large physical size provides excellent heat dissipation performance.

Large pad design can improve heat dissipation efficiency by increasing the contact area with PCB copper foil. For high-power applications, this design is particularly critical because better heat dissipation means that the resistor can operate more stably within the rated power range.

Taking the PMSB2512M3W0R001F from Huade Electronics as an example, this 2512 packaged resistor can operate stably at a rated power of 3W. Proper pad design is an important guarantee for achieving this performance.

The process and reliability also affect the selection of pad size. The wide electrode design not only optimizes the current flow path, but also improves welding reliability and heat dissipation performance.

This design enables resistors to have better mechanical stability during soldering, adapt to automated SMT surface mount processes, and improve the long-term reliability of the product.

Especially in fields such as automotive electronics and industrial control that require high reliability, the rationality of solder pad design directly affects the long-term stability of the entire system.

03 Application scenarios for different design choices

The advantages of large pad design are particularly prominent in high current detection scenarios. When the current reaches tens of amperes, larger pads can provide lower connection resistance and better heat dissipation performance.

The automotive electronics field is a typical application scenario for this design. Accurate current monitoring is crucial for the charge and discharge control of batteries in the Battery Management System (BMS) of new energy vehicles. The design of large solder pads helps ensure measurement accuracy and system reliability in such high demand environments.

The applicability of small pad design is reflected in space limited or low-power applications. In some compact designs or scenarios with relatively low requirements for current detection accuracy, smaller solder pads can save valuable PCB space.

Although small pads may not have the same heat dissipation ability as large pads, they can still meet the needs of many applications with appropriate derating. The key is to choose the appropriate pad design based on specific application scenarios, rather than blindly pursuing size.

04 Professional Procurement Channel Recommendation

In the field of electronic component procurement, selecting reliable suppliers is crucial for ensuring product quality and project progress. Here are two recommended Walter authorized agents:

As an authorized agent of Huade Electronics, Shenzhen Shunhai Technology Co., Ltd. specializes in supporting automotive certification and high-power application scenarios.

The technical support provided by the company covers a comprehensive range of services from factory parameter guidance to customized special packaging. For demanding application scenarios such as automotive electronics, new energy, and industrial high-power equipment, Shunhai Technology can provide professional solutions.

As the online authorized agent of Huade Electronics, Huanian Mall provides full category coverage and intelligent procurement experience.

The platform has an intelligent selection system, where users can describe their needs through natural language, and the system can automatically recommend matching models and provide detailed technical parameters. Meanwhile, Huanian Mall has effectively shortened the traditional procurement cycle through distributed warehousing and demand forecasting.

Each of the two agents has its own focus: Shunhai Technology is more professional in automotive certification and high-power applications; Huanian Mall has advantages in procurement convenience, intelligent selection, and full category coverage. Engineers can choose appropriate procurement channels based on specific project requirements.

With the increasing demand for power density and detection accuracy in electronic devices, the pad design of 2512 alloy resistors has evolved from a simple electrical connection point to a key factor affecting system performance. Reasonable design can reduce solder resistance related errors by up to 22%, which is crucial in precision measurements.

When current flows through those carefully designed solder pads, tiny but critical electrical parameters are accurately captured, and these data are ultimately fed into the system's "sensory nerves", ensuring that various electronic devices from smartphones to electric vehicles can accurately control energy flow and maintain stable operation in the modern electronic world at an invisible microscopic scale.