Recommended product applications for radar (high-precision thin film SMT resistors)

On the one hand, Tesla, which boasted in 2019 about using pure vision to achieve FSD, announced at the end of last year that it would reintegrate a 4D millimeter wave radar into its fourth generation self driving platform; On the other hand, as a potential competitor of LiDAR, the performance of 4D imaging radar is improving, providing higher cost-effectiveness while further squeezing the space of LiDAR.

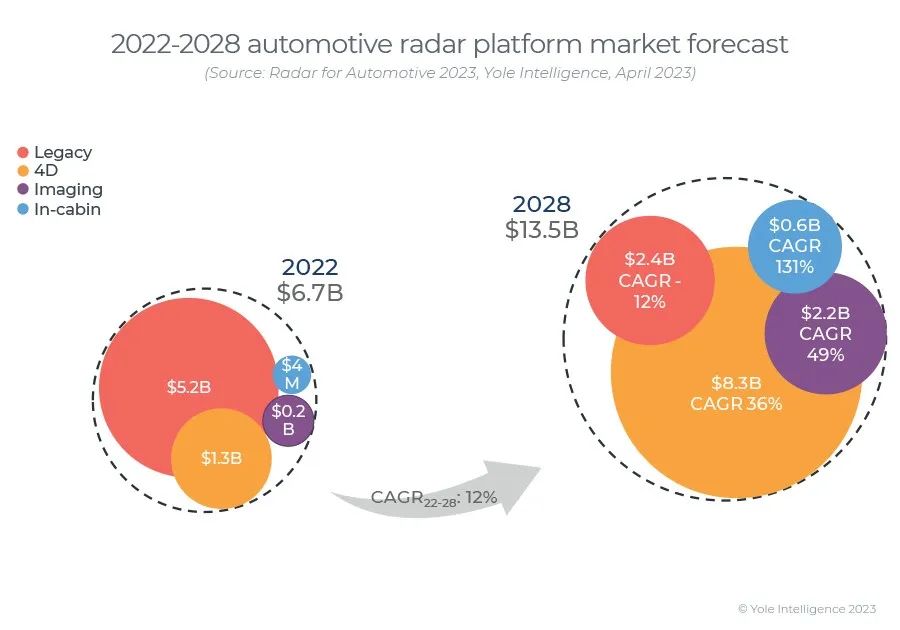

Although there is ongoing debate surrounding this technology, major host manufacturers, Tier 1, and chip companies are openly innovating around 4D imaging radar. According to Yole's statistics, the market size of 4D imaging radar in 2022 is only $200 million. By 2028, this number will increase to $2.2 billion, with a compound annual growth rate of up to 49%.

It can be seen that 4D imaging radar has great potential.

4D imaging radar, not inferior to LiDAR

In fact, millimeter wave radar is not a new technology. It was developed and applied as early as the 1940s and 1950s. But in the past 20 years, what we refer to as millimeter wave radar refers to traditional 3D radar that can measure data in three aspects: distance, velocity, and horizontal angle. In general ADAS applications, such radar applications are also sufficient.

But now, with the acceleration of the popularization of intelligent driving, the natural drawbacks of traditional radar, such as poor resolution, low pedestrian reflectivity, noise, and being only used to detect moving targets, making it difficult to distinguish other stationary objects (such as roads, fences, signs, etc.), are infinitely magnified. But some natural characteristics of millimeter wave radar make them a choice for automotive intelligence solutions.

Therefore, the entire industry has put forward new requirements for millimeter wave radar.

For example, the radar used to require a detection distance of about 100 meters, but now many projects require 150 meters, and the front radar even requires a detection distance of over 300 meters; At the same time, when radar is required to be able to see far, weak targets at close range must also be well detected; In terms of point cloud count, in the past, radar generally required around 300 point clouds per frame, but now, this data needs to reach 1000 or even 2000.

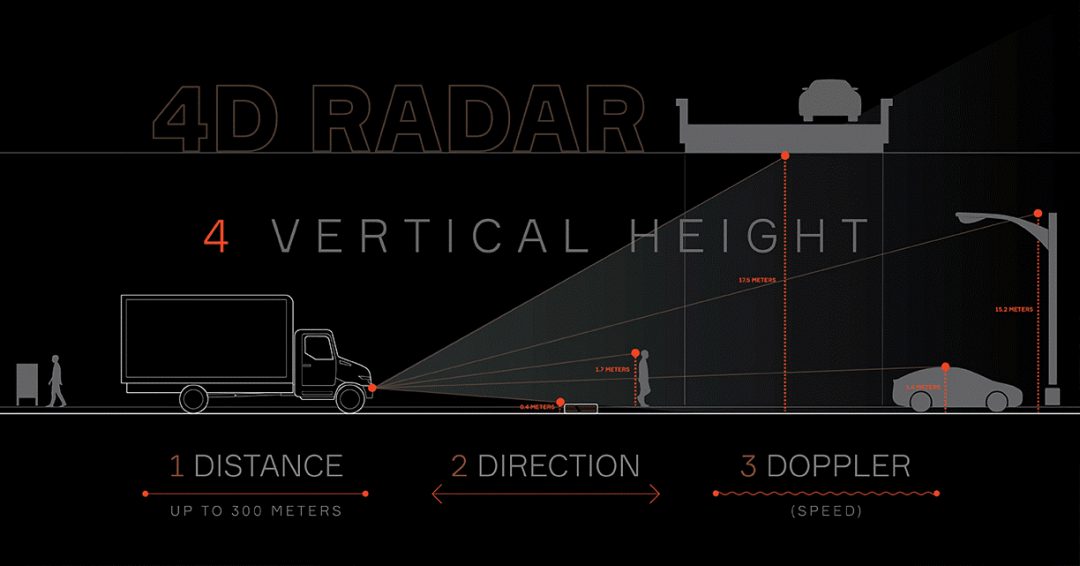

To address the aforementioned issues, 4D imaging radar - a radar that adds a vertical angle detection on top of traditional radar, improves output point density, and has higher resolution capabilities - quickly became popular.

Display of the working principle of 4D radar

(picture source:IoT Automotive News)

Due to significant improvements in resolution, recognition distance, and point cloud count, 4D imaging radar can detect data such as relative velocity, distance, azimuth, and altitude. Meanwhile, the 4D imaging radar also has a sufficiently high dynamic range to distinguish small obstacles at long distances. Furthermore, it can recognize objects such as road signs, static objects, and objects beyond a long distance, which traditional millimeter wave radar cannot achieve.

Dr. Chen Jiashu, founder and CEO of Gatlan Microelectronics Technology Co., Ltd. (hereinafter referred to as "Gatlan"), also told the semiconductor industry observation that the difference between 4D imaging radar and traditional ADAS radar is mainly reflected in two aspects: first, the angular resolution ability is more than twice that of the latter, and second, the number of point clouds is also increased by an order of magnitude compared to the latter. "Therefore, 4D imaging radar requires more MIMO channels, stronger computing power, and more storage resources," Dr. Chen Jiashu emphasized. He further pointed out that in many scenarios, 4D imaging radar even has multiple advantages that LiDAR does not have.

Firstly, as an optical radar, LiDAR optical sensors have inherent drawbacks, just like the human eye, that is, they do not work in rainy, foggy, strong light weather, and interference situations. However, millimeter wave radar is the only sensor that is all-weather, weather free, and not affected by light. Secondly, millimeter wave radar is more accurate in speed measurement and has advantages over optical sensors in handling complex scenes. Furthermore, the popularity of active safety, including the recent NHTSA's 2029 standard AEB system for all vehicles, requires the cooperation of millimeter wave radar. In addition, from a cost perspective, LiDAR has indeed become increasingly cheap. However, regardless of the cost of LiDAR,... How to reduce it? It will still be several times more expensive than millimeter wave radar, and the difference between the two will be maintained at 5 to 10 times Dr. Chen Jiashu continued.

Dr. Chen Jiashu, Founder and CEO of Gatlan

It is worth mentioning that in the middle of last year, Bosch, the world's leading Tier 1 supplier, announced that it would withdraw from the development of laser radar sensors for high-end autonomous vehicle and reallocate resources to millimeter wave radar and other sensing technologies, which is enough to prove that millimeter wave radar technology is promising.

In the era of 4D imaging radar, these advantages are particularly evident. Especially as millimeter wave radar moves from gallium arsenide and silicon germanium manufacturing in the past to the era of CMOS manufacturing, suppliers are able to provide solutions with higher integration, better performance, and better cost, further consolidating the position of 4D imaging radar in intelligent driving.

The huge market prospects have attracted both traditional and emerging millimeter wave radar tycoons to enter this market.

Crowds of heroes compete, local manufacturers break through

We have to admit that, like many other chips, the millimeter wave radar market has always been monopolized by overseas giants.

According to Yole's statistics, the six major companies, Continental Group, Bosch, Hella, Amperex, Denso, and Veoneer, control the millimeter wave radar market. Specifically, in terms of chips, the $1.8 billion market is mainly divided among manufacturers such as NXP and Infineon. After entering the 4D imaging radar market, the overall competitive landscape has not changed much. The leading chip manufacturers in millimeter wave technology are basically still leading suppliers of 4D imaging radar chips, but there are many new competitors emerging.

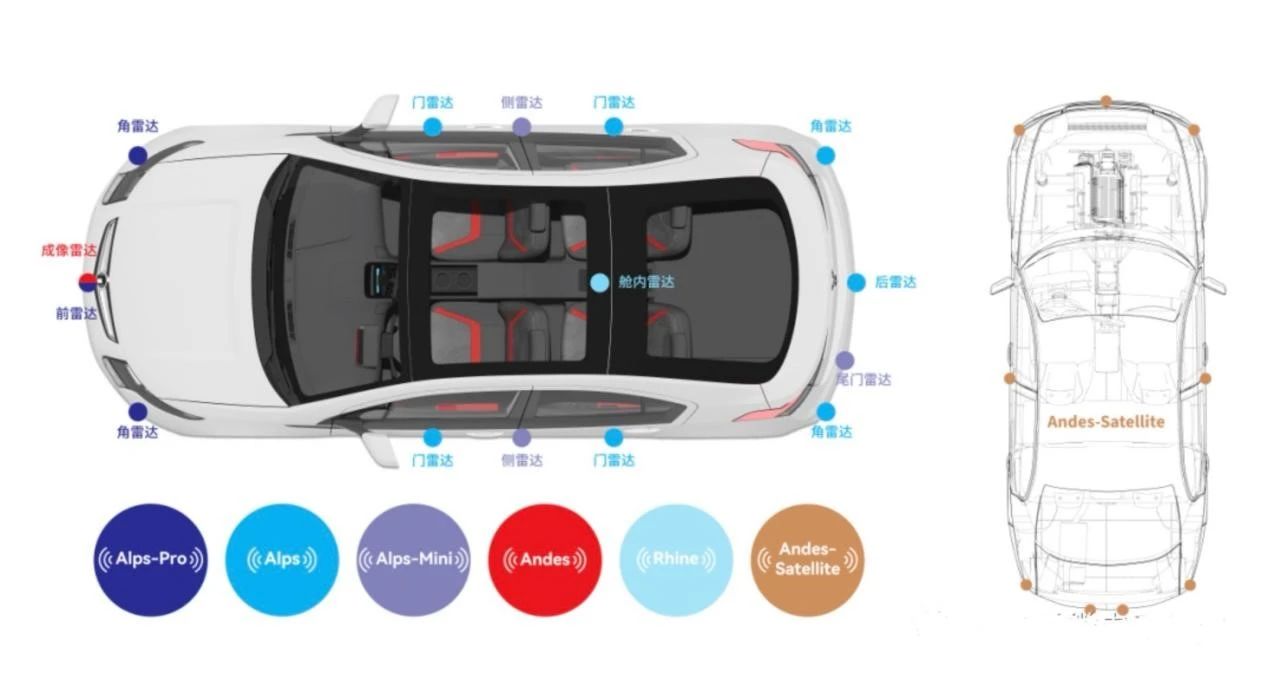

Ruisa expands its influence in the radar market by acquiring Steradian; Arbe launched the car mounted 4D millimeter wave radar product as early as 2019; Mobileye, which excels in making ADAS chips, has also emerged in this field; Altos Radar launched its groundbreaking 4D imaging radar at the 2024 CES. Gatlan has also recently launched a dual chip cascaded imaging radar solution based on the Andes platform, joining the increasingly hot 4D imaging radar market.

In the current rapid rise of new energy vehicles, the release of Gatlan's plan is particularly important.

"In terms of products, we compete with our competitors through differentiation in architecture and innovation to achieve a leap in radar system performance," said Liu Hongquan, Technical Director of Gatlan, when discussing the company's layout in the 4D imaging radar market. "Compared with the current solutions on the market, Andes' solution basically represents the forefront of millimeter wave radar technology, integrating many powerful functions, and can achieve 4D high-end radar and imaging radar functions." Liu Hongquan added that.

Technically speaking, the innovative solution for 4D imaging radar aims to improve resolution and other performance indicators to meet the requirements of ADAS/AD applications. To achieve higher resolution, a larger aperture is required, which is related to the number of transmission and reception channels and antenna array design. Therefore, in terms of RF modules, the Andes scheme includes a 7-bit phase shifter designed based on transmission lines to achieve better MIMO performance and optimized layout, which helps to achieve better isolation; The multi-level waveform loading architecture can support flexible generation of various waveforms, precise digital compensation units, and other functions; The integrated JTAG, Aurora's multiple interfaces, multiple data channels, and analysis modules enable the solution to be easily debugged.

For 4D imaging radar, another focus is on how to integrate more TX/RX channels in a single system to improve its resolution. In response to this issue, Gatlan has introduced a flexible cascading technology based on fully self-developed C2C (chip to chip) interfaces in the Andes scheme, which flexibly cascades multiple chips, potentially reducing the complexity of hardware design and optimizing the overall size and power consumption of radar sensors. In terms of software development, developers can also reuse the same software as when cascading multiple chips, which further reduces their development costs. It is worth mentioning that these cascaded SoCs not only achieve synchronization in RF simulation, forming larger transceiver arrays, but also enable data exchange and synchronization.

Andes SoC芯片以及Andes SoC Two piece cascade reference design scheme

In order to meet the processing needs brought about by the large increase in data volume, Gatlan has provided Andes with more powerful performance and computing power, which not only includes the RSP (Radar Signal Processor) that can achieve ultra fast processing of radar signals, a DSP core with a computing speed of up to 23G MACs, but also a quad core CPU with over 2500 DMIPS computing power, making Andes more confident in processing data.

"Andes' RSP can also change the data flow, accelerator configuration, implement new algorithms, and increase the flexibility of the solution through instructions and software code. This is vastly different from the fixed data flow design of BBA in the past, which is in line with the current trend of software defined cars," Liu Hongquan emphasized.

Meanwhile, in terms of network security, which is of great concern to both customers and consumers, Andes chips adopt a "security island" design and support hardware accelerators for commonly used encryption and decryption algorithms, providing technical support for user privacy protection and network security. In addition, in response to the challenges of complex development, long landing cycles, and high costs faced by 4D imaging radar solutions, Gatlan also supports a "Ready to deploy" turnkey solution, providing convenience for accelerating the widespread application of 4D imaging radar in smart cars.

"The improvement of system integration will bring reliability challenges and increase design difficulty. There are not many companies that can achieve this level, which is also one of Gatlan's strengths and our technical advantage." Liu Hongquan summarized. "This also makes the company one of the few global suppliers that can provide SoC single-chip solutions," Liu Hongquan continued.

Over the past decade of accumulation, Gatlan has shipped a total of 8 million radar chips as of Q1 this year. The company's products have also entered more than 20 car companies, achieving over 200 vehicle models. Looking ahead to the next decade, Gatlan aims to become a global leader in millimeter wave radar chips, promoting millimeter wave radar as a truly inclusive technology.

To achieve this goal, Gatlan has launched products specifically for applications related to active safety in automobiles. At the same time, Gatlan will also make product layouts for applications in smart homes, smart elderly care, industrial automation, and smart cities, aiming to better serve people's daily lives with millimeter wave sensing technology.

Write at the end

Although unanimously optimistic, from the current situation in the industry, 4D imaging radar still faces significant challenges.

For example, in order to improve the resolution of the radar, we can choose to increase its operating frequency. However, due to regulatory limitations on radar frequency, this cannot be easily changed. Of course, we can also choose to achieve higher resolution by increasing the aperture size, but this design can easily bring challenges such as product size being too large, difficult to dissipate heat, and not easy to integrate on the bumper. The accompanying software complexity is also another challenge that 4D imaging radar players have to face.

Combined with the high specifications of the devices required by the application itself, the popularization of 4D imaging radar in the automotive market will not be an easy task.

But in Dr. Chen Jiashu's view, with the demand for L2+deployment and the trend of car manufacturers hoping to replace LiDAR with 4D imaging radar in the market, 4D imaging radar is bound to have huge growth space in the future. To this end, suppliers need to further reduce the cost of radar, while also improving the detection capability of 4D imaging radar.

This is not only the development direction of Gatlan, but also the common goal of all 4D imaging radars.