As a leading enterprise in the global circuit protection field, Littelfuse's fuse production network covers multiple countries and regions to meet the demands of the global market. The following is a detailed analysis of its core production base and global layout:

1、 US headquarters and local production

Headquarters and Historical Origins

Lite was founded in 1927 and is headquartered in Chicago, Illinois, USA. It started with the research and production of small fast melting fuses in its early days. At present, there are still important production facilities in the United States, such as Desplanis (headquarters), Akola (power fuse factory), and Centralia (electronic fuse factory) in Illinois.

Technology research and development and high-end product production

The US factory focuses on the research and development of high reliability products (such as military grade fuses) and core technologies, such as the sub small fuses provided for NASA's space program and Autofuse ® Innovative products such as car fuses.

2、 Chinese production base

Lite's production layout in China is an important pillar of its global supply chain, covering multiple key cities:

Suzhou factory

Suzhou Lite Auvis Fuse Co., Ltd.: Established in 1995, it is Lite's first factory in China, located in Suzhou Industrial Park, covering an area of 9020 square meters and employing approximately 600 people. We mainly produce tubular fuses, automotive fuses, etc., and supply them to domestic and foreign markets.

Product coverage: including fuses for industrial, consumer electronics, and automotive fields, while providing technical support and after-sales service.

Wuxi factory

Lite On Semiconductor (Wuxi) Co., Ltd.: Established in 2002, it is one of Lite On's largest semiconductor production bases in the world, undertaking the transfer of production lines from the United States, Mexico, and other places. Focusing on the manufacturing of semiconductor related circuit protection products.

Dongguan factory

Dongguan Lingte Electronics Co., Ltd.: Established in 2007, located in Humen Town, mainly produces varistors and related circuit protection products, serving the automotive, industrial equipment, and consumer electronics fields.

Other factories

Some materials mention that Lite On also has factories in Kunshan and Shanghai in China, further expanding its production capacity and regional coverage.

3、 Layout in other regions of the world

Europe and other regions of Asia

Lite On has manufacturing and sales centers in Europe (such as Switzerland, UK), Latin America, the Middle East, and Africa. For example, factories in Switzerland and the UK obtained ISO certification as early as the 1980s, supporting the demand of the European market.

Asia Pacific market

The Asia Pacific region is an important market for Lite On. In addition to China, we also have partners and distribution networks in Japan, South Korea, and other places, such as partnering with Shanghai Tanghui Electronics Co., Ltd. to provide localized services.

4、 Production characteristics and quality control

Standardization and Certification

Lite factories generally pass certifications such as ISO 9001 and TS 16949 (automotive industry standards) to ensure that their products meet international quality requirements. For example, products from Chinese factories have passed certifications such as RoHS and UL, meeting environmental and safety standards.

Automation and scalability

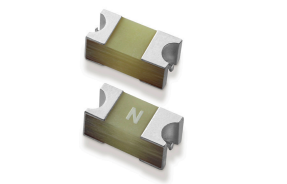

Adopting automated processes such as surface mount technology (SMT) to improve production efficiency. For example, the Suzhou factory supports large-scale production, with an annual output of hundreds of millions of pieces.

The production network of Lite On fuses is centered around the United States as the core technology research and development center, with China as the large-scale manufacturing base (Suzhou, Wuxi, Dongguan, etc.), supplemented by regional factories and partners in Europe, Asia Pacific, and other regions, forming a global supply chain system. This layout not only reduces production costs, but also quickly responds to market demand through localized services, covering multiple fields such as consumer electronics, automotive, and industrial equipment. For specific product origin information, please refer to the product label or contact official channels for confirmation.