Global Safety Certification Standard Guide for Disposable Fuses

In the latest mandatory product certification catalog of the State Administration for Market Regulation, fuse links are prominently listed. For every enterprise that needs to use or produce disposable fuses, this means that they must go through a strict safety certification process.

Fuse links are clearly classified as "circuit switches and electrical devices for protection or connection" in the China CCC mandatory product certification catalog. The purpose of safety certification is to ensure that fuses can reliably melt in the event of a malfunction, preventing safety accidents such as fire and electric shock.

Different markets around the world have their own systems and requirements for the safety certification of disposable fuses.

01 International General Standards

The standards developed by the International Electrotechnical Commission (IEC) are the basis for global fuse safety certification. The IEC 60127 series is a core standard specifically designed for miniature fuses.

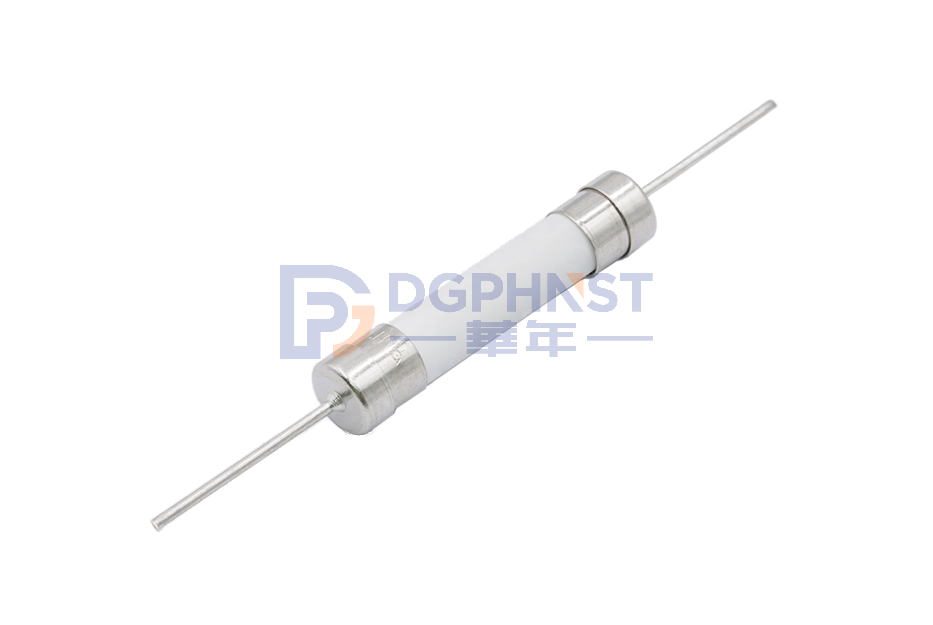

IEC 601271 specifies general requirements, while IEC 601272 specifically applies to tubular fuses, with common sizes of 5 × 20mm and 6.3 × 32mm.

These standards cover comprehensive requirements such as electrical performance, breaking capacity, durability, and labeling, providing a basis for protecting electrical and electronic equipment and their components used indoors.

For smaller applications, IEC 601273 specifies ultra small fuses suitable for printed circuit boards. This section of the standard defines special testing methods in addition to the general requirements.

It is worth mentioning that IEC 6088421:2025 specifically targets plugs with fuses, clarifying that the fuses in such plugs are mainly used to protect the flexible cables connected to the plug, rather than protecting the appliance itself.

02 Regional and National Standards

In the North American market, UL standards dominate. Part 5 of the UL 4248 series specifically addresses the safety requirements for G-class fuse holders.

This type of certification ensures that the fit between the fuse holder and the fuse meets safety standards, preventing overheating, arcing, and fire risks.

The European market typically adopts EN standards converted from IEC standards by the European Committee for Standardization (CENELEC), such as the EN 60127 series. These standards are highly consistent with IEC standards and are an important basis for products to obtain the CE mark.

The DIN EN 601273:2015 published by the German Institute for Standardization (DIN) is a representative of this type of standard, which is equivalent to adopting EN standards and has guiding significance for products sold in Germany.

The IEC 602693 standard provides standardized fuse systems suitable for non professionals, especially the "gG" type universal fuse links. This type of system prevents the misuse of fuse links with higher rated currents through mechanical design, ensuring the protection function of cables and lines.

03 Compulsory Product Certification

In the Chinese market, fuse links are explicitly listed in the mandatory product certification (CCC certification) catalog. This means that fuse links produced, sold, or imported domestically must pass CCC certification and bear the CCC mark.

According to the revised catalog in 2023, "fuse links" are classified under the category of "circuit switches and electrical devices for protection or connection". For small fuses used in whole machine products, they also need to be assessed as safety critical components when applying for CCC certification.

The main standard for certification is the GB/T 9364 series (equivalent to the IEC 60127 series), and the number of samples may be 4866 depending on the specific product and applicable standards.

04 Comparison of Core Standards in Different Markets

For ease of understanding, the following table summarizes the core safety certification requirements for disposable fuses in major global markets:

|Market/Region | Core Standard System | Examples of Main Applicable Standards | Scope of Applicable Products | Key Features|

|International standard | IEC standard | IEC 601271/2/3 | Miniature tubular fuse links, ultra small fuse links | Global technical benchmark, focusing on electrical performance and safety parameters|

|North American market | UL standard | UL 42485 | G-class fuse holder and related fuse links | Focus on fire prevention and connect with NEC electrical specifications|

|European market | EN standard (based on IEC) | EN 60127 series, IEC 602693 | Miniature fuses, fuses for non professionals | CE marking basis, emphasizing non interchangeability and user safety|

|Chinese market | CCC certification | GB/T 9364 series | All fuse links sold domestically | Mandatory certification, dual control of the whole machine and components|

05 Certification Testing and Process Points

The safety certification testing of disposable fuses usually includes multiple rigorous evaluations. The breaking ability test verifies the ability of the fuse to safely cut off the fault current under short-circuit conditions; The time current characteristic test confirms whether the melting speed under different overload levels meets the nominal characteristics.

Durability testing verifies the long-term reliability of fuses by simulating repeated load cycles. The clarity and durability of markings and identification are also key aspects of certification testing, especially for products with limited space such as ultra small fuse links.

For enterprises applying for certification, the process usually includes submitting the application to the certification body, providing samples for type testing, accepting factory inspections to ensure continuous compliance, and ultimately obtaining the certification certificate and maintaining its validity.

It is worth noting that the required number of fuse samples for different rated currents varies. For example, when testing according to standards, a single rated current test may require up to 66 samples.

With the release of the new version of IEC 6088421 standard in 2025, the technical requirements for plugs with fuses have been updated, reflecting the continuous evolution of the field of fuse safety certification.

The major global markets are gradually strengthening the regulation of basic protective components such as fuses to ensure the bottom line of electrical safety. Disposable fuses are no longer simple "disposable components", but safety critical components that need to be taken seriously. Their safety certification is a necessary condition for products to enter the market rather than an optional option.

HNST WELCOME! 0755-23173910

English |中文

你当前的浏览器版本过低或不支持。请升级或更换浏览器。推荐浏览器 Chrome Edge。