I. Product Overview

The CRW1218 series current sensing resistors are high-performance electronic components manufactured using thick-film wide-terminal chip technology. Featuring a compact size, lightweight design, high reliability, and excellent quality, they accurately meet the core requirements of current detection in various electronic devices. The unique wide-terminal structure not only optimizes current-carrying capacity but also enhances heat dissipation efficiency, ensuring stable operation under complex working conditions. These resistors are widely used in navigation equipment, power supplies, lighting equipment, indoor lighting systems, central door locking systems, and other electronic devices.

II. Core Electrical Specifications

(I) Standard Electrical Parameters

- Rated Power (at 70℃): 1W, enabling continuous and stable power output at an ambient temperature of 70℃ to ensure long-term reliable operation of the component.

- Maximum Working Voltage: 200V, adaptable to various voltage scenarios and meeting the power supply requirements of different devices.

- Maximum Overload Voltage: Complies with product specifications, capable of withstanding short-term overload pressure to improve operational safety.

- Temperature Coefficient of Resistance (T.C.R.): ±200 PPM/℃ for resistance range 1Ω≤R<10Ω; ±100 PPM/℃ for 10Ω≤R≤10MΩ. Excellent temperature stability ensures minimal resistance change in a wide temperature range.

- Resistance Range: 1Ω to 10MΩ, available in two accuracy grades: F (±1%) and J (±5%), allowing selection based on practical application scenarios.

(II) High-Power Electrical Parameters

For higher power output requirements, the CRW1218 series can switch to high-power mode. The rated power (at 70℃) is increased to 2W, the maximum working voltage remains 200V, the T.C.R. is uniformly optimized to ±100 PPM/℃, and the resistance range is maintained at 1Ω to 10MΩ with accuracy grades F (±1%) and J (±5%), meeting the stringent requirements of high-power devices.

(III) Low-Ohm Specifications

For low-resistance detection scenarios, the low-ohm models of the CRW1218 series perform exceptionally well: rated power (at 70℃) is 1W, rated voltage range is 0.10~0.99V, and maximum overload voltage is 2.475V; T.C.R. adjusts according to the resistance range: ±1800 PPM/℃ for 10mΩ≤R<50mΩ, ±800 PPM/℃ for 50mΩ≤R<100mΩ, and ±600 PPM/℃ for 100mΩ≤R<1000mΩ, accurately adapting to low-resistance current sensing needs.

(IV) Operating Temperature Range

The entire series operates within a temperature range of -55℃~+155℃, capable of adapting to extreme high and low-temperature environments. Whether in harsh outdoor cold conditions or high-temperature internal device environments, it can maintain stable electrical performance.

III. Physical Dimensions and Packaging Information

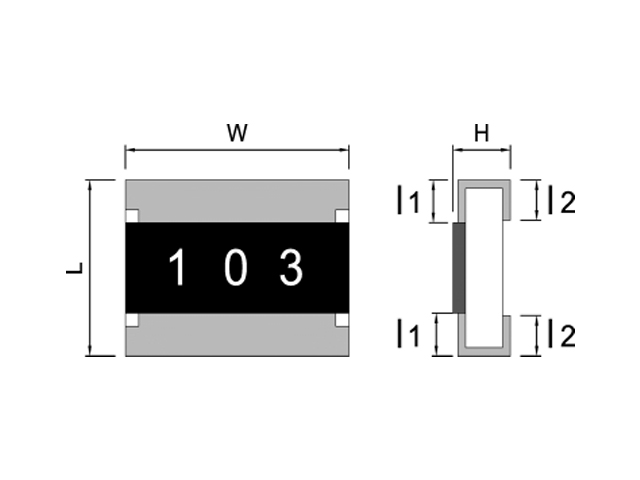

(I) Product Dimensions (Unit: mm)

- Length (L): 3.10±0.10

- Width (W): 4.60±0.10

- Height (H): 0.55±0.05

- Terminal Length 1 (l1): 0.40±0.20

- Terminal Length 2 (l2): 0.50±0.20

- The compact size design facilitates flexible layout within limited PCB space.

(II) Recommended Land Pattern (Unit: mm)

To ensure good soldering effect and stable electrical connection, the recommended land dimensions are as follows:

- A: 2.04

- B: 4.24

- C: 4.80

(III) Packaging Specifications

- Reel Specification: 7” reel, 4K/Reel

- Packaging Type: Supports both Paper Taping and Embossed Taping. For Paper Taping, relevant dimensions include A=3.30±0.2mm, B=4.60±0.2mm, W=12±0.1mm, etc.; for Embossed Taping, corresponding dimensions are A=3.30±0.2mm, B=4.60±0.2mm, W=12±0.1mm, etc., adapting to different production and assembly processes.

IV. Performance Characteristics and Reliability Tests

(I) Power Derating Characteristics

The power rating of the product is based on continuous full-load operation at an ambient temperature of 70℃. When the ambient temperature exceeds 70℃, the load should be reduced accordingly in accordance with the power derating curve to ensure the service life and stable performance of the component.

(II) Voltage and Current Rating Calculation

For products with resistance ≥1Ω, the rated voltage can be calculated using the formula E(RCW V)=√(P×R) (where P is the rated power and R is the nominal resistance), ensuring safe operation within the rated power and voltage range.

(III) Stringent Reliability Tests

The CRW1218 series has passed multiple authoritative standard tests, demonstrating excellent performance:

- Temperature Coefficient of Resistance (T.C.R.) Test: Conducted in accordance with JIS-C-5201-1 4.8 and IEC-60115-1 4.8 standards, with 25℃ as the reference temperature, tested at -55℃ and +155℃, and the results meet the specification requirements.

- Short-Time Overload Test: In accordance with JIS-C-5201-1 4.13 and IEC-60115-1 4.13 standards, apply 5 times the rated power or the maximum overload voltage (whichever is smaller) for 5 seconds. After the test, the resistance change meets: ±(1.0%+0.05Ω) for accuracy ≤1%, and ±(2.0%+0.10Ω) for 2% and 5% accuracy.

- Resistance to Soldering Heat Test: Held at 260±5℃ for 10 seconds. After the test, the resistance change meets strict standards: ±(0.5%+0.05Ω) for accuracy ≤1%, and ±(1.0%+0.05Ω) for 2% and 5% accuracy.

- Rapid Change of Temperature Test: 5 cycles between -55℃ and +155℃, with resistance change meeting relevant requirements, demonstrating excellent environmental adaptability.

- Other Tests: Including Resistance to Solvent Test, Damp Heat with Load Test, Load Life (Endurance) Test, Insulation Resistance Test, and Bending Strength Test, all certified by authoritative standards, ensuring long-term reliability of the product under various complex working conditions.

V. Soldering and Storage Recommendations

(I) Soldering Parameters

- Wave Soldering: Temperature 260℃, duration 10 seconds, maximum 2 soldering cycles allowed.

- Solder Reflow: Peak temperature 265℃, duration at 260℃ for 10 seconds, maximum preheating time 20 seconds, heating rate 3K/s, cooling rate ≤6K/s, maximum 3 reflow cycles allowed.

- Rework Temperature: 350℃ for 3~5 seconds when using hot air equipment.

It is recommended to use infrared, vapor phase oven, or hot air oven for reflow soldering to avoid product performance damage caused by exceeding the recommended temperature profile.

(II) Storage Conditions

The product should be stored in an environment with temperature 25±5℃ and humidity 60±20%, with a shelf life of one year from the date of delivery. During storage, ensure the front and back lead lengths meet requirements (front lead ≥400mm, back lead ≥120mm (30PCS) or ≥200mm (50PCS)), the paper tape pulling speed is 300mm/min, and the top adhesive peel-off strength is 10~70g to maintain intact packaging.

VI. Conclusion

The CRW1218 series current sensing resistors demonstrate significant advantages in the field of current detection with their precise resistance accuracy, stable temperature characteristics, excellent reliability, and flexible packaging options. Their wide operating temperature range, high-power adaptability, and stringent reliability test guarantees enable them to perfectly fit various application scenarios such as navigation equipment, power supply systems, and lighting equipment, providing core support for the stable operation of electronic devices. Whether for industrial equipment pursuing high-precision detection or consumer electronic products emphasizing stability, the CRW1218 series is a trustworthy current sensing solution, helping customers optimize and upgrade product performance.