(1) What are the configurations required for communication between Siemens 200 PLC and King View through MPI protocol?

1) Install the STEP7 Microwin 3.2 programming software provided by Siemens for the computer running Configuration King, as our driver program needs to utilize the MPI interface library functions provided by the software;

2) Install the MPI communication card CP5611 in the slot of the computer, and use a dedicated cable and network connector provided by Siemens to connect the CP5611 card to the Port port of S7-200 (pins 3 and 8 of the CP5611 card are connected to port 3 and 8 of S7200 respectively). Generally, the terminal resistance of the last network connector in the MPI network should be set to ON state;

3) Create an MPI network in the PLC and correctly set the communication baud rate;

4) Set SetPG/PC interface parameters in the control panel, please refer to the electronic help document of King View for details.

(2) How does the hardware connect between the King of View and Siemens 200 PLC using a free port protocol via modem communication?

A standard PPI cable needs to be inserted into the device, and the 9-pin port of the modem is connected to the PPI cable through a standard 232 crossover cable. The 232 crossover requires pins 1, 4, and 6 to be short circuited on the modem side, and pins 7 and 8 to be short circuited.

(3) Can S7-200 PLC communicate with two upper computers through serial port connection?

It is not feasible to use serial cables, but the following options can be considered:

1) Configure the PLC to the MPI protocol, with each upper computer configured with an MPI card;

2) One PC serves as the collection station to communicate with the PLC, while the other PC serves as the client to communicate with the collection station.

(4) What is the possible reason why Siemens 200 PLC failed to communicate with King View through the PPI protocol?

Please check the following settings:

1) User programming cable dialing settings: The fifth terminal is used to set the communication protocol. A dialing of 0 indicates PPI/Freeport, and a dialing of 1 indicates PPI (master). When communicating with King View using the PPI protocol, select the dialing value corresponding to PPI/Freeport;

2) PPI communication transmits 11 bits of data. It is recommended to set 8 data bits, 1 stop bit, and even parity (default is 11 bits), and ensure that the baud rate of the PLC is consistent with PPI and the King view;

3) Programming software must start and run the King of View in an offline state.

(5) How does the register address defined in the View King correspond to the PLC address when Siemens 200 PLC communicates with the View King through the Modbus protocol?

The mapping relationship is as follows: 0 corresponds to Q, 1 corresponds to I, and 3, 4, 8, and 9 correspond to V. The correspondence between the dd numbers of 3, 4, 8, and 9 and the offset address of the V register in the PLC (actual address -1000) is: in the configuration king (register dd number -1) * 2=the offset address of the V register in the PLC. For example, in View King, 40031 corresponds to PLC's VW1060 (register 4 in View King represents a SHORT type variable), and 90640 corresponds to PLC's VD2278 (register 9 in View King represents a FLOAT type variable).

(6) What precautions should be taken when Siemens 200 PLC communicates with King View through Modbus protocol?

The following points need to be noted:

1) The corresponding initialization program (KVmoddbus. mwp) needs to be downloaded from the PLC. This program is provided by Asia Control and defaults to using the PLC's port 0 port with address 2 and baud rate 9600, without verification (the address and baud rate can be modified through VB8 and SMB30 in SBR0);

2) Due to the fact that the PLC Modbus protocol program occupies V1000 and earlier addresses, users should avoid using V-zone addresses that conflict with the Modbus protocol when writing logic control programs;

3) When the Siemens S7200 PLC communicates with the King of View through the Modbus protocol, the switch on the CPU must be in the RUN state, otherwise the Modbus communication program in the PLC is not running, resulting in the failure of communication between the King of View and the device through the free port protocol.

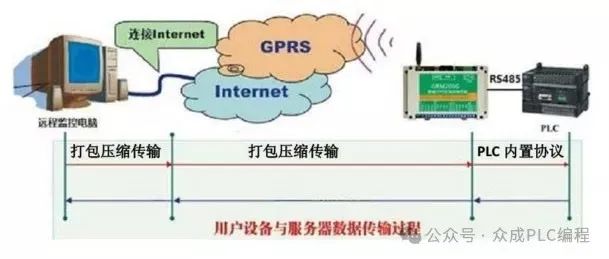

(7) Does the MPI cable method of S7 300 support communication with King View via GPRS?

Not supported. The GPRS communication method of Configuration King requires data communication through the created virtual serial port, while the MPI protocol achieves communication with the PLC by calling Siemens PLC's dedicated dynamic connection library (such as s7onlinx. DLL), rather than directly communicating through the serial port. Drivers similar to calling methods also do not support GPRS connections.

(8) How should the device address be defined when communicating with multiple Siemens S7-300 and 400 PLCs through the DP protocol using the Configuration King?

When using the DP protocol to communicate with multiple Siemens S7-300 and 400 PLCs, the definition of device addresses mainly follows the following steps:

1) Hardware connection: Ensure that the CP5611 (or CP5613) card is inserted into the computer to connect multiple S7-300/400 PLCs on one DP bus.

2) DP protocol setting: All PLCs must be set as DP Slave stations, and CP5611 (or CP5613) card must be set as the unique Master station of DP through Simatic net software.

3) Definition of device address in Configuration King: In Configuration King, select PLC/Siemens/S7-300/400 series (DP)/Profibus DP. The setting of the device address is not fixed at 1.1, but needs to be configured based on the actual address of each slave PLC. The address settings here are related to the address settings of the slave PLC in the DP network. Each slave PLC should have a unique address in the DP network.

(9) Can Siemens 300 PLC achieve dual device redundancy when communicating with King View through MPI communication card?

Yes, by using MPI communication cards and specific configurations, the communication between Siemens 300 PLC and King View can achieve dual device redundancy. The specific implementation method is as follows:

1) Hardware connection: Use CP5611 card to connect two S7-300 PLCs, and use programmable plugs provided by Siemens to achieve this connection.

2) Device address setting: In the KingView software, set different device addresses for these two PLCs, such as 7.2 and 8.2. The number before the decimal point represents the address of the PLC, while the number after the decimal point represents the slot number where the CPU is located. These two PLCs should be defined separately in the STEP7 programming software, and the slot numbers should be the same except for different PLC addresses.

3) Variable definition: In the configuration king, only the variables of the main device need to be defined. When the main device fails, the system will automatically switch to the backup device.

(10) What communication links are supported for communication between King of View and Siemens 300 and 400 PLCs? Do you need support from Siemens software?

The communication between King View and Siemens 300 and 400 PLCs supports multiple communication links, including:

1) MPI cable communication method: STEP7 programming software needs to be installed on the computer where the Configuration King is located.

2) MPI communication card method: It is also necessary to install STEP7 programming software on the computer where the Configuration King is located.

3) Ethernet communication method: This method usually does not require the installation of STEP7 or Simatic net communication software on the computer where the Configuration King is located.

4) Profibus DP communication method: requires the installation of STEP7 programming software and Simatic net 6.0 (or higher) communication configuration software and authorization on the local machine.

5) Profibus-S7 communication method: STEP7 programming software needs to be installed on the computer where the King View is located, but Simatic net software does not need to be installed.