The two biggest cost drivers in cold plate manufacturing are thermal conductivity requirements and annual demand, which are usually little or no control by thermal engineers and manufacturing engineers. However, you can reduce costs by understanding how roughness, flatness, hardness, surface morphology, installation characteristics, and liquid connection specifications affect the cost of cold plates. By involving cold plate manufacturers in the early stages of the design process, you will be able to identify manufacturing cost drivers and select the most cost-effective design.

Most cold plates are made of aluminum, but some new technologies use copper. Although copper has better thermal conductivity, aluminum is used more frequently because it is usually cheaper, lighter, and easier to use. The processing of copper is very difficult and expensive. The two most popular aluminum cold plate technologies currently are tubular and vacuum brazing (see Figure 1). A tubular cold plate is usually a copper or stainless steel tube pressed into an aluminum profile groove. They have excellent cost advantages and provide excellent cooling solutions for medium and low power density devices. The vacuum brazing cold plate is composed of two metallurgically bonded plates and inner fins. They come in various sizes to choose from and offer extremely high performance, making them an ideal choice for heat load concentration applications. The working time of tube and vacuum brazing cold plate technology is limited.

After the above factors, the biggest cost driving factors for aluminum cold plates are processing time and additional processing steps. Cold plate manufacturers typically have costs related to processing time, including depreciation costs for machines, power supplies, consumables, and maintenance. Therefore, the longer the cold plate is placed in the manufacturing equipment, the higher the cost. Each additional processing step will continue to drive up costs.

(1) Extruded parts and die castings

In order to minimize processing time and lower costs, it is best to use extrusion and casting as much as possible. Squeezing is generated by pushing metal through a mold to create an object with a fixed cross-section. The mold used for new extrusion is relatively inexpensive, and the extrusion size is limited to about 9 inches (22.86 centimeters) wide. The extrusion wall thickness needs to be relatively consistent, and any channel or feature needs to be straight. Manufacturers can also combine extrusion and machining to reduce costs. Certain features can be squeezed, and then more complex features can be processed. This will help reduce extrusion costs, provided that you consider extrusion characteristics when designing the sheet. Another option is to combine casting and machining to manufacture cold plates. For example, if the casting is not smooth enough, a second operation is required to achieve the required flatness specification for the cold plate. Usually, the minimum purchase quantity for extrusion or casting is very high, so you need to apply them correctly to justify the use of these processes. Both extrusion and casting can save a significant amount of cost overall.

(2) Surface roughness

Surface roughness (smoothness) may increase costs significantly, but has little impact on performance. Contrary to some people's views, roughness has a relatively small impact on the thermal performance of cold plates. In most applications, the surface contact between the cold plate and the component is less than 10% or the air gap exceeds 90%. A smoother surface will only slightly reduce the percentage of air gap. The surface finish of a typical machined cold plate is 32-64 μ in (81-163 μ cm), which is sufficient for most applications. Using a standard machining center can reduce the roughness to 16 μ in (41 μ cm), but this requires a more robust fixture to reduce any potential chatter and slow machining head speed and feed rate. The speed is the rate at which the cutting tool rotates, and the feed is the rate at which the machine head moves on the cold plate. Reducing the speed and feed rate means that the machining center time is longer, thereby increasing costs.

Most applications use thermal interface materials (TIM) between components or circuit boards and cold boards to help minimize gaps. TIM should be as thin as possible, as its relatively high thermal resistance greatly masks any conductivity improvement with a smoother surface. Increasing the clamping force of components or plates on cold plates can also help offset higher roughness, but may increase stress on the plates or components. When the cold plate and components or circuit board are heated up, clamping stress can also increase the effect of thermal expansion coefficient (CTE) mismatch.

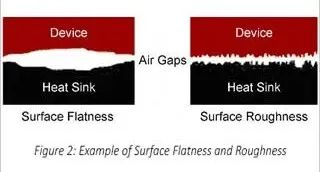

(3) Surface flatness

Compared with surface roughness, surface smoothness has a greater impact on the thermal performance of cold plates, as if the cold plate is not smooth, the contact area will be greatly reduced (see Figure 2). The standard flatness specification is 0.001 inches per inch (0.003 centimeters per centimeter). Therefore, within a range of one inch from the measurement point, the lowest point of the cold plate will not be 0.001 inches (0.003 centimeters) lower than the highest point. If flatness is required to be better than 0.001 inches per inch (0.003 centimeters per centimeter), one cost-effective method is to specify local flatness rather than the tight flatness of the entire board. For example, if multiple insulated gate bipolar transistors (IGBTs) are to be installed on a cold board, and each IGBT requires 0.001 inches per inch (0.003 centimeters per centimeter) on the entire substrate, specify the local flatness of the individual IGBTs instead of requiring the entire board to be very flat.

(4) Surface morphology

Minimizing surface morphology is also important for reducing costs, especially for circuit board applications. Complex surface morphology typically requires starting with thick aluminum blocks and then machining off unwanted aluminum. This leads to high raw material costs and long processing times. If the morphology cannot be eliminated, bundling highly similar components onto the circuit board can reduce processing requirements.

(5) Hardness

Cast, extruded, or vacuum brazed cold plates are very soft after processing, usually with only T0 hardness. Cold plates must be hardened because soft aluminum is difficult to process and handle. To increase the hardness from T0 to T4, it is necessary to perform heat treatment on the cold plate. The heat treatment process involves heating the cold plate to 1000 ° F (538 ° C), allowing it to remain at that temperature for approximately 1 hour per inch of cold plate thickness, and then subjecting it to thermal shock by rapidly cooling it (see Figure 3). One method of cooling the cold plate is to directly drop it out of the furnace and place it in a water bath. To bring the cold plate from T4 to T6, artificial aging must be performed on the cold plate. This is achieved by placing the cold plate at 300 ° F-400 ° F (149 ° C-204 ° C) for 8-16 hours. T6 provides very hard cold plates with high tensile strength, which is a typical requirement for military and aerospace applications. However, for most applications, T4 is already difficult enough, and specifying T6 will only increase unnecessary costs.

(6) Installation features/holes

Another cost increasing factor in cold plate manufacturing is the increase in holes. A hole may increase the cost of the cold plate by up to $3. One of the main reasons for the increased cost of drilling is the inability to drill holes in the fluid path. Therefore, for tubular cold plates, it is necessary to bend the pipes to accommodate the holes, and each bend will increase the cost. For vacuum brazing cold plates, an island must be created in the fluid path, which also means performing electrical discharge machining (EDM) on the internal fins. This will increase processing time significantly, thereby increasing costs.

Strict tolerances on the position and spacing of holes can also drive up costs. The reasonable tolerance specification is ± 0.005 inches (± 0.013 centimeters). Like flatness, specifying local tolerances as much as possible will reduce costs. For large cold plates with holes relatively far apart from each other, tolerances become more difficult to maintain. One of the reasons is that the machine tool tolerance increases with the extension of the head movement distance. Another reason is that there may be a thermal gradient of up to 18 ° F (10 ° C) in the machining workshop, which can cause the cold plate to expand or contract up to 0.005 inches (± 0.013 centimeters). Through holes are the easiest to specify stricter tolerances because their creation is done through a single tool operation, while threaded holes are less likely to have tolerances because making them involves two tools. Spiral oil is the most difficult to tolerance because the process requires a tapping hole, and spiral oil itself has tolerances. All tolerances add up to make manufacturing more difficult and expensive. Avoiding small tapping holes can also help reduce costs. Hole sizes of 4-40 or smaller become difficult to tap as the tap may break during drilling. To minimize this issue as much as possible, the running speed of the machine must be much slower. One method to address strict tolerance requirements for cold boards is to increase the size of mounting holes on components or circuit boards.

(7) Liquid connection

For liquid connections, straight threaded O-ring female ports usually have the best effect. In addition to the welding system, it also provides the best sealing at the lowest cost. Pipeline connections (such as NPT joints) cannot provide the required accuracy for components such as cold plates. On vacuum brazing cold plates, the use of external threaded fittings, such as barbs or bead fittings, should be avoided as it requires other operations (such as welding) to connect the fittings. In addition, accessories beyond the cold plate need to be protected during transportation, which may increase packaging costs. Quick disconnections should only be used when necessary, as their cost per pair can reach up to $750. Cold boards or electronic devices that require frequent replacement need to be quickly disconnected. For cold plates that are already filled with coolant, they are also needed. For liquid connections, another factor to consider is port tolerance. Usually, the incoming pipeline has a certain degree of flexibility. A reasonable tolerance is between ± 0.030 inches (0.076 centimeters) and ± 0.060 inches (0.152 centimeters).