List of Chip Capacitor Selection and Purchase Address: Click on the image to enter

hnstshop.com/product-list/C01-p1-l10.html" target="_blank" rel="noopener">

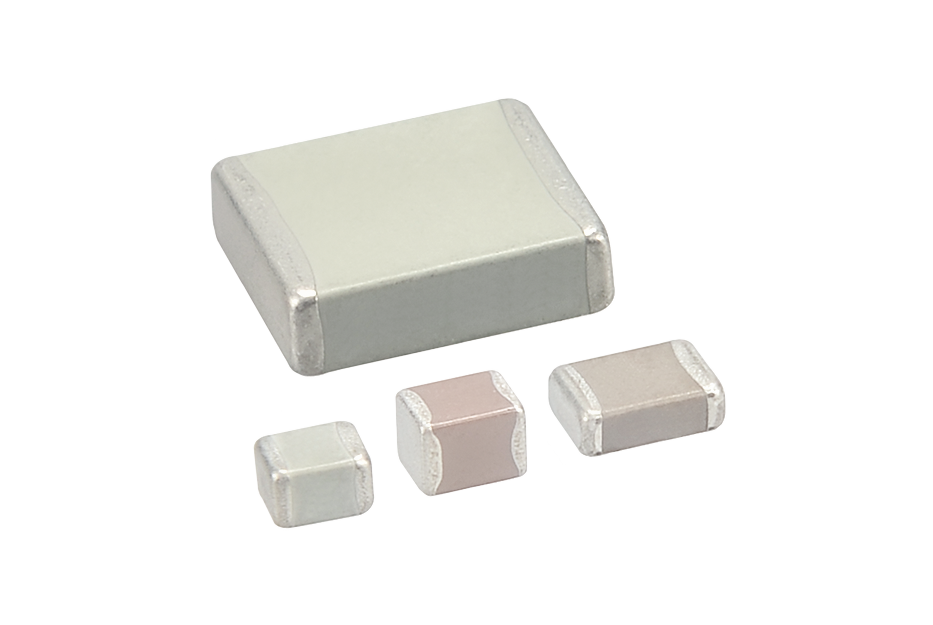

Chip capacitors and tantalum chip capacitors are two common types of chip capacitors in electronic components. They have some differences in structure, materials, performance, and applications.

Firstly, patch capacitors are composed of insulating material (i.e. dielectric) between two metal plates (i.e. electrodes). This type of capacitor can be manufactured from different materials, such as ceramics, polymers, or aluminum electrolytes. The capacitance value of patch capacitors is usually small, ranging from a few picoseconds (pF) to a few picoseconds( μ F) Between. They are typically used for high-frequency applications, such as RF circuits and filters.

Secondly, SMD tantalum capacitors are a special type of SMD capacitor, with a capacitor layer made of tantalum metal. Tantalum is a highly conductive material, so the chip tantalum capacitor has lower ESR (Equivalent series resistance) and higher energy density. This makes them have good performance in high-frequency and high-power applications. The capacitance value of SMT tantalum capacitors is usually large, usually within a few micrometers( μ F) Between a few milliliters (mF).

Thirdly, in terms of capacitance value, chip tantalum capacitors are usually larger than chip capacitors. This makes them more common in circuits that require storing more charges or providing larger capacitance values. In addition, chip tantalum capacitors typically have a lower ESR, which makes them more suitable for applications that require low resistance and high frequency.

Fourthly, in terms of size, SMD capacitors and SMD tantalum capacitors usually have similar appearances and dimensions. They all adopt SMD packaging, which can be easily installed on circuit boards. This makes them easier to use in compact spaces and high-density circuits.

Fifth: There is a significant price difference between chip capacitors and chip tantalum capacitors. Usually, the price of tantalum chip capacitors is higher than that of chip capacitors. This is because SMT tantalum capacitors use more expensive materials and manufacturing processes.

Sixth: There are still some limitations in chip tantalum capacitors compared to chip capacitors. Due to the special properties of tantalum metal, when using SMT tantalum capacitors, attention should be paid to avoiding excessive voltage, temperature, and current. If these limiting conditions are exceeded, chip tantalum capacitors may malfunction or short-circuit.

Overall, there are some differences in structure, materials, performance, and applications between chip capacitors and chip tantalum capacitors. Chip capacitors are usually used for applications with smaller capacitance values, while chip tantalum capacitors are suitable for larger capacitance values and high-frequency applications. The choice of capacitor depends on specific application requirements and cost considerations.