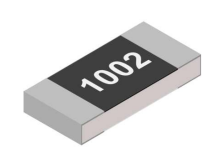

High precision resistors mainly refer to high-precision resistance values and ultra-high product stability, that is, low PPM of the product, which means that the resistance value of the product changes little when the temperature changes. The application of precision resistors is becoming increasingly widespread. The following will explain the main application scenarios of high-precision resistors.

High precision resistor is a component specifically used for measuring and adjusting physical quantities such as current, voltage, power, etc. Its accuracy can reach one millionth or higher, and it has a wide range of applications in various fields. The following is a detailed introduction to its application scenarios:

1、 Electronic manufacturing industry

In the electronic manufacturing industry, the welding of electronic components requires extremely high precision and quality, especially in the production of consumer electronic products such as mobile phones, computers, and tablets. High precision resistors can be used to ensure consistency and reliability of small solder joints. With the development of smartphones towards slimness, multifunctionality, and high performance, higher requirements have been put forward for the quantity, size, precision, and applicable power of smartphone components, including high-precision resistors. For example, in terms of 5G communication technology, the transmission rate of 5G has increased by 1-2 orders of magnitude compared to 4G. Therefore, the RF design of 5G mobile phones is more complex, and the use of RF front-end devices such as filters and power amplifiers has increased. More high-precision resistors are also needed for current detection to ensure the normal operation of the circuit.

2、 Automotive manufacturing industry

The automotive industry has very high requirements for welding technology, and high-precision resistors can achieve spot welding and seam welding of body parts. In the automotive electronics industry, the role of precision resistors is crucial to meet vehicle safety, fuel economy, and emission regulations. Especially in the manufacturing of new energy vehicle battery modules, high-precision resistance welding power supplies ensure the reliability and consistency of battery cell welding with their superior current control and welding uniformity, thereby improving the service life and safety of battery packs.

3、 Household appliance industry

In the production process of household appliances, the welding requirements for internal circuits and precision components are high, involving a variety of materials such as copper, aluminum, nickel, etc. High precision resistors have precise adjustment capabilities for different materials, which can effectively meet the welding needs of various materials, avoid problems such as poor welding and short circuits, and ensure the stability and service life of household appliances.

4、 Medical device field

The welding accuracy of medical devices is directly related to the functionality and safety of the equipment, especially in the manufacturing of precision medical devices and implantable devices. The strict requirements for welding have led to the widespread application of high-precision resistors. For example, medical devices such as electrocardiograms, blood glucose meters, and blood pressure monitors require high-precision resistors to ensure the accuracy of measurement results. By precisely controlling parameters such as welding time, welding current, and voltage, high-precision resistors can achieve stable welding of small medical devices and complex metal structures, ensuring product consistency, non-destructive testing, and high-strength welding effects.

5、 Communication industry

High precision resistors play an important role in communication equipment. RF transceivers, antennas, and other communication devices require high-precision resistors to control the resistance value in the circuit, which plays a key role in achieving data transmission and wireless communication. With the continuous development of communication technology, the performance requirements for communication equipment are also increasing, and the application of high-precision resistors is becoming more and more widespread.

6、 Aerospace field

The manufacturing of aerospace equipment requires welding processes to withstand extreme environmental conditions such as high temperature, low temperature, strong vibration, etc. High precision resistors can ensure the strength and fatigue resistance of welded components in this field, especially in the manufacturing of aircraft structural components, engine parts, and satellite electronic equipment. Their precise control ability ensures the stability and reliability of welding quality.

7、 Industrial control system

In industrial control systems, long-term operation requires stable resistance values and high pulse load capacity. High precision resistors can meet these requirements and ensure the stable operation of industrial control systems.

In summary, high-precision resistors have a wide range of applications in various fields such as electronic manufacturing, automotive manufacturing, household appliances, medical equipment, communication, aerospace, military equipment, and industrial control systems. With the continuous development of technology, the application scenarios of high-precision resistors will continue to expand and deepen.