Installation method and precautions for self recovering fuses (PPTC)

1、 Typical installation method

PCB soldering integration

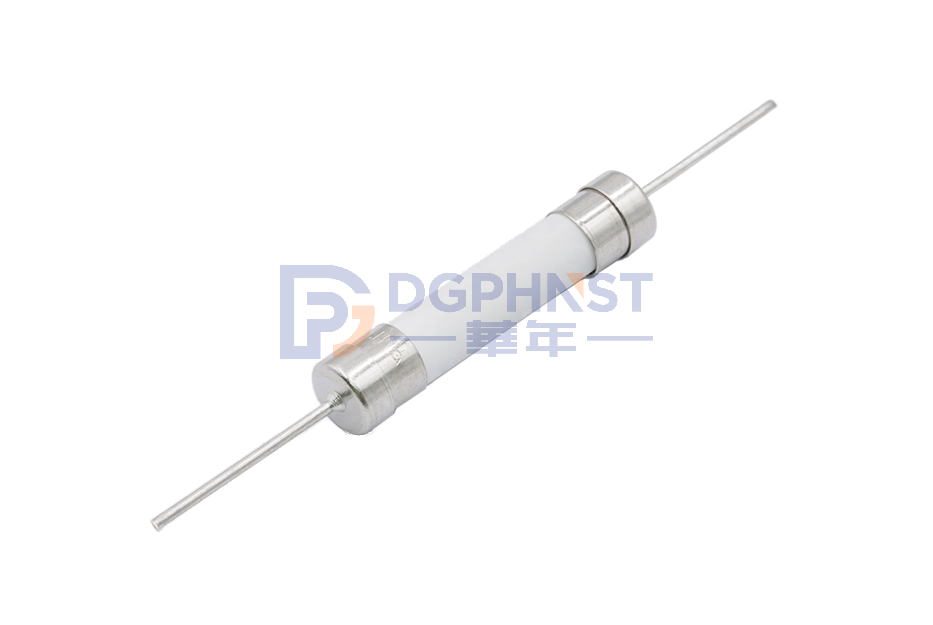

(1) Direct insertion packaging (such as radial leads)

Adopting through-hole soldering technology, suitable for double-sided PCB layout

Suggest reserving a lead length of 35mm to avoid thermal stress damage

The installation direction should maintain a safe distance from the surrounding heating elements

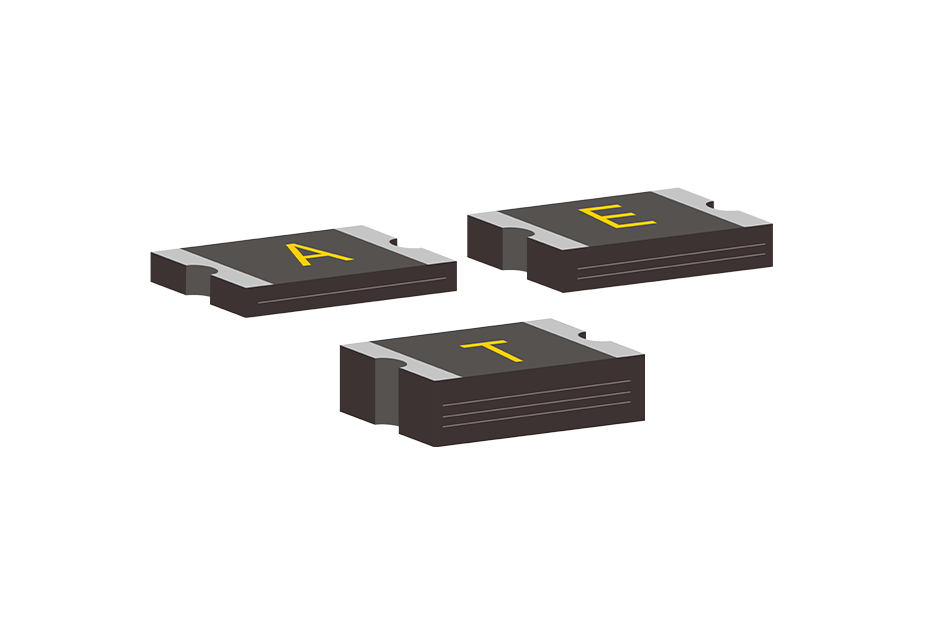

(2) Surface mount packaging (SMD type)

Priority should be given to using reflow soldering technology, and the temperature curve should comply with the device specifications

Pad design should follow the heat capacity requirements in the device manual

A moisture-proof isolation zone needs to be set up to avoid residual soldering flux

Terminal type wiring installation

(1) Wire harness series connection method

When using crimping terminals, it is necessary to ensure that the contact area is ≥ 1.5 times the wire diameter

Suggest using circular terminals with anti loosening screws for fixation

Multiple strands of wire need to be tinned to prevent loose threads

(2) Equipment level installation

Set up dedicated installation brackets inside the distribution box

Maintain a vertical installation posture to optimize heat dissipation

It is recommended to install an arc extinguishing device at the power input end

2、 Special scenario configuration plan

Multi channel parallel topology

Need to configure a current sharing resistor (recommended resistance of 0.10.5 Ω)

Parallel devices should maintain a temperature difference of ≤ 2 ℃

The layout should ensure symmetrical routing length

Installation in high temperature environment

Fill the gap between the device and the heat sink with thermal conductive adhesive

The installation location should avoid the active heat source radiation area

Suggested derating use (15% derating for every 10 ℃ increase in temperature)

3、 Key points of engineering practice

Space layout criteria

Maintain a distance of ≥ 10mm from the electrolytic capacitor

Prohibit parallel installation of high-power inductive components

The length of the detection end wiring should be ≤ 30mm

Reliability enhancement measures

Control pressure ≤ 2MPa during secondary injection molding packaging

The vibration environment requires the addition of silicone shock absorbers

Three proof paint should be applied in humid environments (avoiding electrode areas)

4、 Verification process after installation

Basic parameter testing

DC impedance measurement at room temperature (compared to nominal value ± 20%)

Insulation resistance test (≥ 100M Ω/500VDC)

Functional verification

Overcurrent trigger time test (1.5 times rated current ≤ 60s)

Recovery characteristic detection (impedance recovery of 90% within ≤ 60 seconds after power failure)

5、 Common installation misconceptions

Wrong selection

Mistakenly using the holding current as the trigger current parameter

Neglecting the impact of voltage drop on the system

Process defects

When manually soldering, the contact time of the soldering iron is greater than 3 seconds

Use highly corrosive solvents during cleaning

system matching

Without considering the surge characteristics of capacitive loads

No delay is set when used in conjunction with mechanical circuit breakers

Note: Specific installation requirements should be based on the device specifications. It is recommended to conduct thermal simulation analysis and actual operating condition testing before implementation.