The people who most agree with Wang Chuanfu may include those from the headquarters of lithography giant ASML. Dutch journalist Marc Hijink, who has been tracking ASML for over a decade, told us, "When I ask this question at ASML, they always say that natural forces are the same in Beijing and the Netherlands. There are no laws of physics that prevent others from making similar machines.".

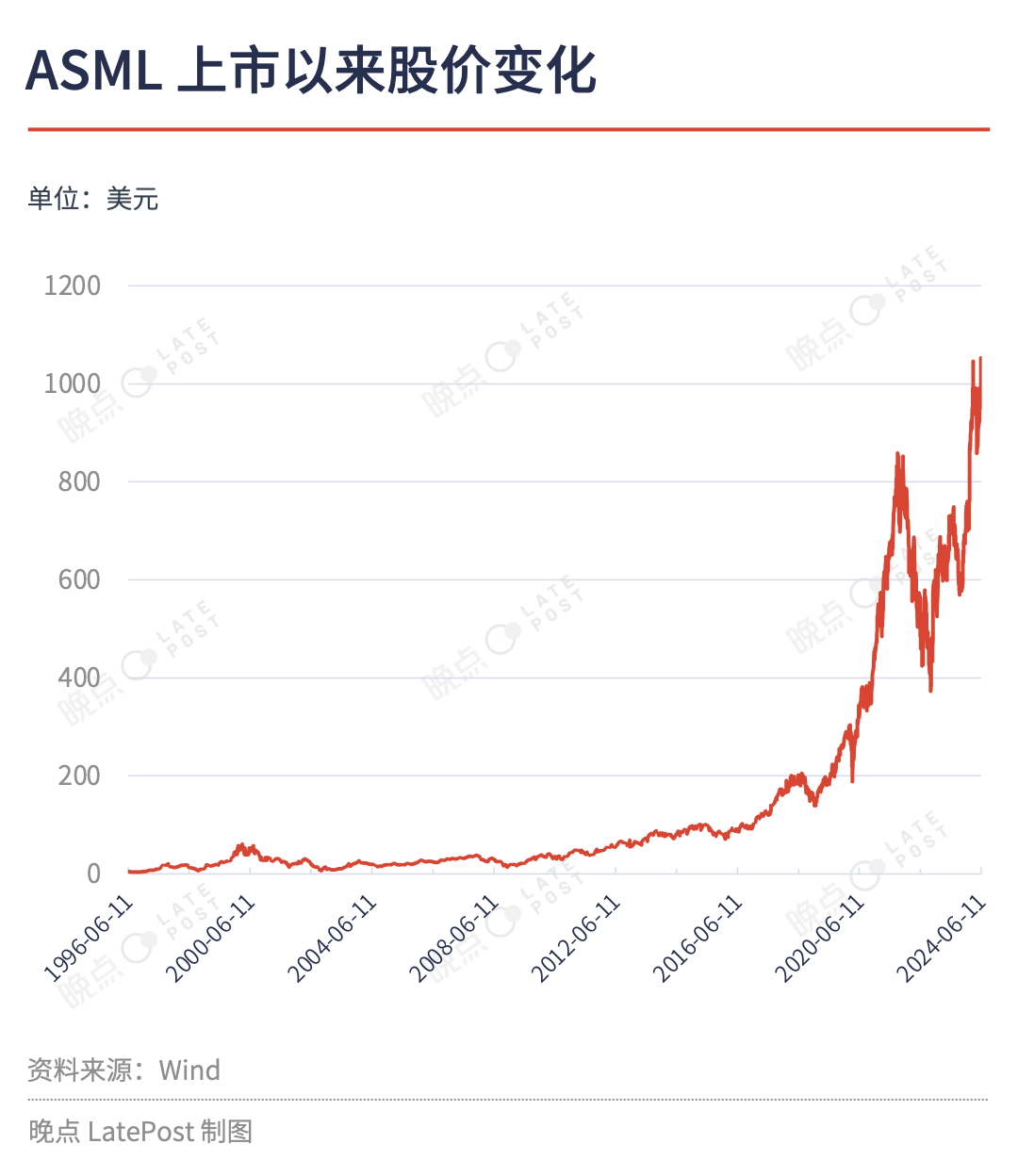

Currently, 90% of the lithography machines sold globally come from ASML. Its exclusive EUV extreme ultraviolet lithography machine is almost the only choice for producing advanced chips, selling for two to three billion US dollars, making it the most expensive luxury item in Europe. ASML's market value also surpassed luxury goods giant LVMH, the parent company of Louis Vuitton, for the first time this year.

Last week, ASML founder Wim Troost passed away at the age of 98. 40 years ago, it was Trost who put in all his effort that Philips did not completely cut off its loss making lithography business and was willing to let them start their own businesses. At the time of ASML's establishment, Trost was almost sixty years old. The first batch of employees also agreed to join after Philips failed their promise to return to work. This is not the entrepreneurial team that venture capitalists like today.

After years of interviews, Hikink believes that in the end, it was a daring gene and ultimate focus that led ASML to where it is today. "If something is not proven to be impossible, they will feel like they might be able to do it," he said in a video conversation with us.

At the end of last year, Hitchcock's new book "Focus: The ASML Way" (Chinese translation unknown, to be released in October this year) was published in Dutch. The previous ASML biography "The Lithography Giants" only talked about 1996, when ASML was not yet the only choice for cutting-edge chips.

Higgink's Focus complements the growth history of ASML after the millennium. With the support of the management, it provides a more holistic perspective to show how ASML has developed from a start-up company to an industry monopolist in 40 years: a small company with questionable prospects chose the most difficult technical route at the beginning of its entrepreneurship, and continued to focus on one goal for 40 years, eventually becoming the most cutting-edge technology manufacturer in the contemporary era. The resulting machine can carve electronic components on silicon chips that are only a fraction of the size of COVID-19.

01

A small company that could go bankrupt by buying a cup of coffee,

Selected the most difficult path

In April 1984, 47 employees moved from Philips's concrete headquarters building to a temporary shelter adjacent to a garbage dump and leaking during rain. ASML was established here.

In the same year, when Apple released the Mac, the computer CPU was already too complex to be machined. Intel's factories use lithography machines to allow fine light to pass through thin films and project invisible patterns onto silicon wafers, forming tiny circuit structures.

The imaging principle of ASML lithography machine: By projecting a beam of light through a mask and optical lens printed with a circuit diagram, the circuit diagram is exposed on a silicon wafer with photoresist.

At this time, Philips had been investing more than ten years in the development of lithography machines, inventing industry-leading alignment systems and a unique electric wafer table. However, it did not have an advantage in fierce competition with ten other manufacturers and never received orders.

As Japanese home appliances swept across the European and American markets, the then CEO of Philips explicitly demanded the end of all unprofitable hobbies, including lithography machines, as soon as possible - either for sale or through joint ventures.

At that time, Trost, who served as a director of Philips Science and Industry (S&I), was one of the few people in the company who supported the development of lithography machines. Some projects of the Ministry of Science and Industry have brought considerable profits to Philips and are relatively financially independent. Philips was unwilling to continue investing, and Trost once bypassed the senior management of the group and used the department's small treasury to support the development of lithography machines.

The first batch of ASML employees, on the other hand, were mostly reluctant to work for a new company that had been spun off by Philips due to the generous pension promised by the Philips union and the promise to return to Philips in a few years.

The office shed in the early days of ASML was located adjacent to a garbage dump and leaked during rain.

Lithography machines were not a particularly profitable business at the time, and even the impact of chips on the world was just beginning. It is difficult to say that Trost sees further than the group management and even the entire industry. But perhaps it was some intuition, a bit of stubbornness, and enough voice that allowed him to almost save this precarious cutting-edge project on his own.

After taking over the lithography machine project, Trost, who had no experience in the chip industry, quickly began looking for joint venture partners. After facing consecutive setbacks in negotiations with American counterparts Cobit, Perkin Elmer, and Varian, he collaborated with ASM International, a Dutch chip equipment company that was also not well-known at the time. According to the joint venture agreement between both parties, Philips and ASM International will each invest $2.1 million in a 50:50 equity ratio.

At that time, Philips, which had an annual revenue of over 14 billion US dollars and R&D investment of over 1.2 billion US dollars, was only willing to receive $300000 in cash for this joint venture project, and the remaining 17 unsold PAS 2000 machines were used to offset the debt. According to Trost's estimate, even with the offsetting machines, $4.2 million is not enough to cover 1/10 of the cost of developing new machines. For this reason, he allowed his S&I department to still bear most of the initial procurement costs of the new company.

Preserving the project is just the beginning. The new company has no orders, zero market share, and even a name that doesn't sound good - its initial abbreviation was ALS, which is also the abbreviation for Amyotrophic Lateral Sclerosis. The management team, who had little knowledge, only renamed the company ASML in 1996.

ASML encountered cyclical weakness in the industry at the beginning of its entrepreneurship, but it actually helped it. In 1985, the global chip market was sluggish, and chip manufacturers reduced equipment purchase orders, which posed inventory and cash flow challenges for top lithography machine manufacturers who needed to purchase and produce several quarters in advance, reducing or even shelving investment in new product research and development.

ASML without orders and a large team does not have these burdens. Hikink tells us that the economic crisis has helped ASML carve out a gap in the fiercely competitive market, and the culture of "nothing to lose" has made them more courageous in facing risks.

ASML's first CEO, Gjalt Smit, learned that chip manufacturers hoped to start producing Very Large Scale Integration (VLSI) in two years, which required lithography machines capable of projecting light with an accuracy of about one micrometer, exceeding the limits of all lithography machines at the time. If ASML can produce such a revolutionary new product within two years, it can seize the new chip cycle. They chose the most difficult path due to their lack of money, time, and fame.

The best way to quickly assemble a complete LEGO set with thousands of components is to find a few friends to work together. The way in which ASML improves the efficiency of lithography machine development is similar. Engineers start from the design stage and divide the lithography machine into 5 modules, which are developed in parallel by different professional teams. Finally, independent modules are assembled into a complete system.

However, the lithography machine only exposes problems after complete assembly, and in order to identify the cause, each module needs to be tested one by one, which is very time-consuming. Project leader Richard George came up with a solution and developed five prototype machines, each team independently testing different modules, further reducing the testing and assembly cycle from two and a half years to six months.

Finally, ASML produced a lithography machine with the code PAS 2500, which was also the world's first modular lithography machine. Thanks to modular design, engineers can quickly turn off or replace lenses, light sources, and other important modules during installation and use, saving wafer fabs a lot of money. This flexibility allows PAS 2500 to continue working 24/7 on production lines in some wafer factories more than 30 years after its release.

Another challenge faced by ASML was its lack of advanced production processes, as competitors Nikon and Canon both had top-notch optical lens production lines at the time. ASML alone cannot build complex machines like lithography machines. It must gather all its brain power, funds, and dexterous hands.

Smith has a passion for aviation and majored in aerospace engineering in college. One of his hobbies was flying gliders, and he also worked for NASA and the European Space Agency. He believes that aircraft manufacturers can learn from them and outsource component production, focusing all their energy on complex machine design.

But at that time, ASML did not have any orders of its own, and it required the highest standard of craftsmanship from the beginning. Many components even needed customization, making it difficult for suppliers to be convinced. For example, the cooperation between ASML and German lens manufacturer Zeiss was very bumpy - Zeiss, which was already supplying top lithography machine company GCA at the time, did not see ASML.

Also, due to the chip downturn cycle, other customers cancelled orders, giving ASML the opportunity to share production capacity with Zeiss. During the collaboration, ASML helped Zeiss identify lens drift issues and opened up a window for future collaboration. In 2007, the two signed a new contract to share risks and profits, and the chip market often experienced severe turbulence. ASML agreed to advance one-third of the lens deposit to reduce the risk of Zeiss purchasing raw materials in advance.

Due to the small shipment volume of lithography machines, ASML can only choose one supplier for each core component and bind the interests of both parties through a separate supply agreement. This kind of cooperative relationship has been maintained to this day.

As of 2023, ASML has registered over 16000 patents, many of which were developed in collaboration with its 5100 suppliers, with Zeiss being the most important partner. Hermann Gerlinger, former CEO of Zeiss, described the two companies as the ultimate combination of machines and optics. "ASML has revealed all its secrets to us, and we have also shared everything with them.".

02

For the first time making a profit and leading the industry,

It's all because we found big clients with consistent styles

The lithography machine of ASML can produce 200 to 300 wafers per hour at the fastest, and the terminal product value of each wafer cut into chips can reach hundreds of thousands of dollars, which is more efficient than a banknote printer. As long as it can help chip manufacturers save on the cost of producing chips, customers are eager to pay for lithography machines no matter how expensive they may be.

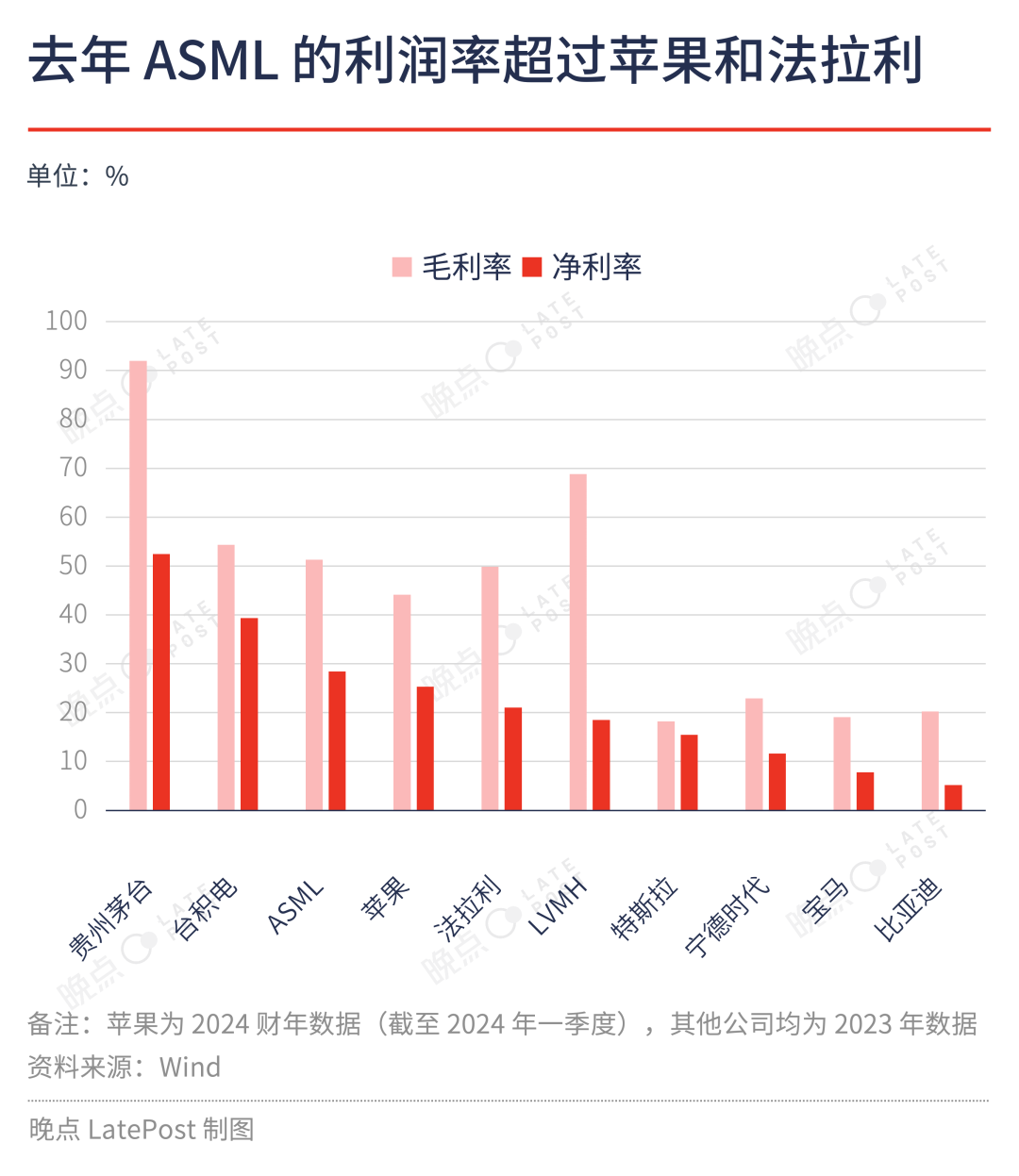

In 2023, ASML's gross profit margin exceeded 51% and net profit margin exceeded 28%, both higher than Apple and Ferrari, which sold high-end consumer goods during the same period. Industrial equipment companies do not have much brand premium, and such exaggerated profit margins can only come from absolute technological leadership.

But this profit is based on absolute technological leadership and market share, which cannot be achieved, and lithography machines may also be a losing business. Until the late 1980s, ASML was still a loss making company. Even 20 years ago, it was not considered a tech giant, with a market value of only about one thousandth of what it is today.

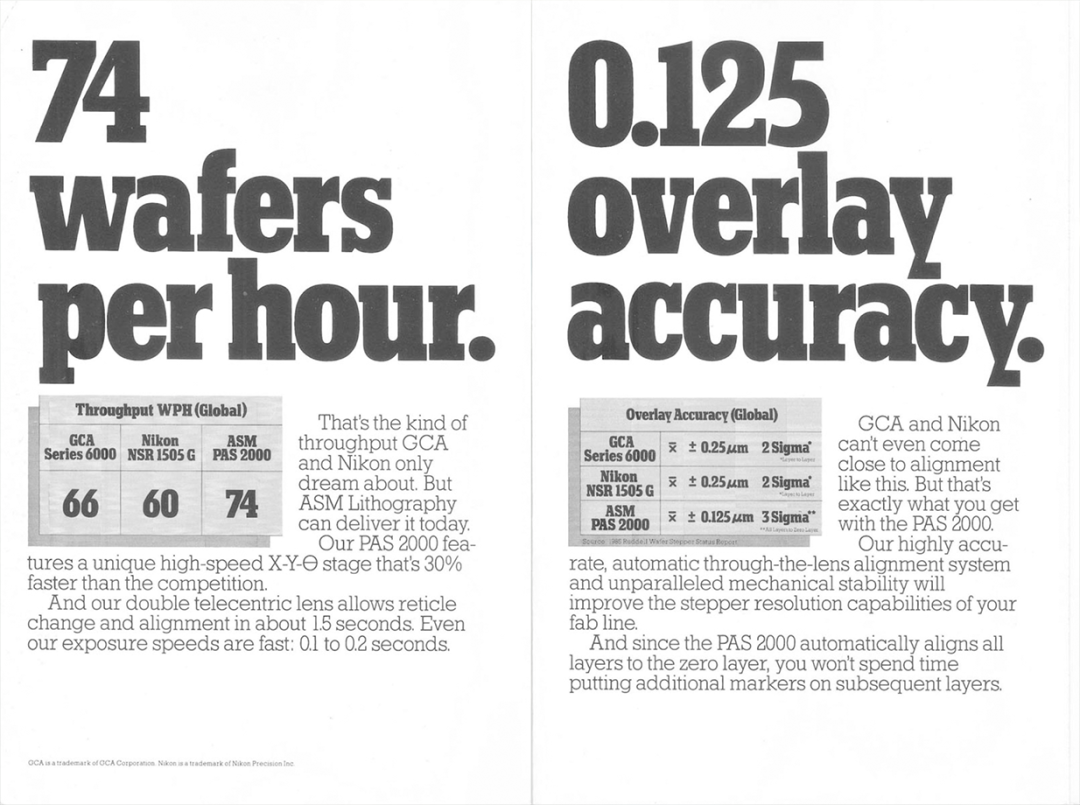

When the company was still very small, Smith could only follow the customer's needs and request orders. At the SEMICON West exhibition in 1985, ASML printed a brochure and selected benchmark products from its strongest competitors GCA and Nikon, with only parameters that had an advantage over itself.

During the exhibition, ASML's advertising brochure focuses on promoting its own products with better efficiency and accuracy, without mentioning any non competitive shots.

At the dinner of this exhibition, Jerry Sanders, founder of chip manufacturer AMD, complained that the quality and service of American chip equipment manufacturers were too poor, and AMD had to purchase equipment from Japanese companies. Upon learning of this, Smith immediately rushed to the United States to discuss countermeasures with the marketing experts he hired.

Soon, an advertisement titled "We Heard You, Jerry" appeared in news media and industry journals, claiming that ASML's lithography machines can meet AMD's reliability requirements. They will identify and improve issues in the factory together with the customer after delivery. This advertisement failed to help ASML immediately secure AMD's order. But with deeper services, ASML has opened the door to AMD and laid the foundation for future cooperation.

Normally, a well maintained lithography machine can ensure normal operation for 98% -99% of the time, with most malfunctions coming from human factors such as loose cables and bolts, fingerprints and scratches on the lens. But lithography machines are very complex, and the chip production line cannot stop for a moment. Any small problem can have an impact.

A chip factory at Intel used to have inexplicably declining yield rates for several hours every night. Engineers who searched for the cause but found no results finally discovered that the problem came from the fart of cows near the factory: between 1am and 2am every day, the wind direction changed, and methane emitted from steak entered the clean room through an air purifier, polluting chip production. Intel ultimately had to spend money to move the ranch. Later on, each wafer factory added an extra note when selecting locations - try to avoid cattle farms as much as possible.

Among all the clients, the company with the largest cooperation scale and the most advanced chip manufacturing process with ASML is a company three years younger than it.

In 1987, Zhang Zhongmou founded TSMC and hoped to collaborate with an experienced chip manufacturer, but Japanese manufacturers were not interested and negotiations with Intel and Texas Instruments also broke down. In the end, Zhang Zhongmou contacted Philips, who agreed to exchange chip production technology for a 27.5% stake in TSMC. This equity relationship has also enabled ASML to smoothly become a supplier to TSMC.

TSMC and ASML are very similar. They are all more focused on investing in cutting-edge technologies in a specific niche field than their competitors, and are equally quick and chaotic in facing challenges. Before TSMC, there was no chip manufacturer that only provided OEM services. Chip giants, like Intel, both designed and built factories to manufacture chips. ASML and TSMC engineers often work together to research and solve problems. ASML often receives valuable feedback from TSMC engineers during the development and testing stages of new machines.

Soon, TSMC helped ASML make its first profit - although only temporarily. At the end of 1988, a major fire engulfed TSMC's chip factory, causing dozens of lithography machines to be damaged. TSMC urgently ordered 17 new machines from ASML. This unexpected order helped ASML overcome its financial difficulties in the early stages.

In the late 1990s, transistor architecture continued to iterate, but the wavelength of the lithography machine's light source was stuck at 193 nanometers, making it impossible to carve more precise circuits. The mainstream solution in the industry at that time was to find a way to shorten the wavelength of the light source to 157 nanometers. Nikon and SVG have both invested heavily in this.

In 2002, Lin Benjian, then Deputy Manager of Research and Development at TSMC, proposed at a technical seminar that there was no need to replace the light source. Instead, a layer of water was added between the lens and photoresist to achieve shorter wavelengths through light refraction. The resolution improvement effect was almost twice that of the expensive 157 nanometer solution. This clever approach is called immersion lithography.

However, at that time, mainstream lithography machine manufacturers had already invested hundreds of millions of dollars in 157nm and were unwilling to accept a new adjustment plan. Even some executives from large companies approached the then Chief Operating Officer of TSMC, Jiang Shangyi, hoping that he would "manage his subordinates and not disrupt the situation.".

ASML, which also invested hundreds of millions of dollars in the development of the 157nm solution, is an exception. It decisively cut losses and chose a better immersion route. In 2004, by the time Nikon finally developed a prototype of a 157 nanometer dry lithography machine, the immersion lithography machine developed in collaboration between ASML and TSMC was already very mature.

Another important invention of ASML during the same period, TwinScan dual scanning worktable, also achieved great success. To ensure layer alignment, the wafer must be measured before exposure, and TwinScan was the first lithography system with a dual wafer working platform. When a wafer on one platform is being exposed, the wafer on the other platform is being aligned and measured, and then the two platforms exchange positions. The wafer originally on the second platform continues to be exposed, and the first platform replaces the next wafer for alignment and measurement.

This parallel solution can greatly improve the production efficiency of lithography machines and is very compatible with immersion lithography - if the traditional single platform solution is still used, the original measurement system will not work properly due to water interference, but TwinScan has already separated measurement and exposure, perfectly avoiding this problem.

Immersion lithography and TwinScan have enabled ASML to gradually surpass Nikon. Before the emergence of these two technologies, ASML had a market share of less than 10%, but by 2007, ASML had already captured nearly 60% of the market share.

03

Pursuing a single goal at no cost,

Becoming the most irreplaceable company

In the first quarter of 2023, Berkshire Hathaway, which adheres to long-term principles, rarely sold TSMC stocks that it only held for a few months. Vice Chairman Charles Munger later explained that TSMC is a good company, but he doesn't like the chip business because "chips are constantly iterating, and every time they upgrade, manufacturers have to throw in all the money they earned in the previous round.".

The current monopoly of ASML is built on a key technology that has taken 20 years and billions of dollars - EUV (Extreme Ultraviolet) lithography.

In the late 1990s, when the chip industry was looking for next-generation lithography solutions, extreme ultraviolet (EUV) light with a wavelength of only 13.5 nanometers was also a potential choice. But obtaining EUV light is too difficult as it cannot pass through any object, including air. The closest EUV light in nature is in the sun. Lithography machine manufacturers must produce EUV light themselves and accurately guide it into the lithography machine.

Japanese companies were the first to start related experiments, followed closely by American and Dutch companies. In 1997, Intel and the US Department of Energy, realizing how difficult the next generation of light sources could be, led the formation of the EUV LLC alliance, bringing in the then mobile phone giant Motorola, old rival AMD, and the three major national laboratories in the United States in an attempt to overcome the EUV problem.

Several top lithography machine manufacturers are also invited by Intel, but the US government is concerned about technology leakage and has excluded Japanese companies Nikon and Canon. ASML, on the other hand, squeezed into the EUV LLC alliance with the help of Intel, relying on investment commitments to the United States. This gave it the opportunity to spend $1.6 billion to purchase SVG, an American company with EUV and mirror technology patents.

This collaboration and SVG transaction have laid the foundation for ASML's EUV research and development.

Due to the inability of EUV light to pass through any object, all lenses in the lithography machine need to be replaced with reflectors and can only operate in a vacuum environment. ASML and Zeiss have invested heavily in establishing the world's largest vacuum chamber laboratory to simulate potential problems in vacuum environments.

The manufacturing process of reflective lenses is also very complex, requiring the use of coating technology, stacking dozens of nano layers of different materials to enhance the reflection strength of the lenses. The surface protrusion of each layer cannot exceed 0.01 nanometers, and its imaging accuracy is equivalent to shining a flashlight on the moon, and the resulting spot cannot exceed the size of a coin.

Nevertheless, after multiple reflections, the energy of EUV light will be lost to 1% of its original value, and the first EUV verification machine can only expose 30 wafers per hour. To increase production capacity, it is necessary to enhance the power of light sources.

Light source supplier Cymer (another US company with EUV patents) has reservations about such a highly challenging and only ASML customer technology, and progress has been slow for many years. In 2012, impatient ASML acquired Cymer for $1.95 billion.

In order to raise acquisition funds and additional research and development expenses, ASML took another big gamble by exchanging 23% of the company's shares for 5.3 billion euros from three major clients, Intel, TSMC, and Samsung - more than its annual sales. If research and development fails, it will suffer huge losses.

After taking over Cymer, ASML significantly improved its work efficiency while continuing to invest a lot of manpower and financial resources, finally raising the power of EUV light sources to commercial standards.

During this period, even TSMC, which has always been closely cooperating, once announced the abandonment of EUV and turned to another manufacturer, Mapper, which adopts the electron beam technology route. ASML had to visit Apple, which was in talks with TSMC, to persuade TSMC to purchase EUV through this potential major customer.

ASML, which pursues precision lithography equipment infinitely, TSMC, which is committed to promoting chip manufacturing processes, and Apple, which is determined to upgrade its processors once a year in pursuit of competitive advantage, have formed a perfect combination, investing hundreds of billions of dollars annually in cutting-edge chip manufacturing technology paid by iPhone users.

In this collaboration, ASML has completely monopolized the global lithography machine market with EUV, leaving only some relatively low-end and niche areas for Nikon and Canon. Apple, TSMC, and ASML also use advanced chips produced by EUV technology to create a virtuous profit cycle.

Focused and unreserved continued investment in the most advanced technology is ASML, which is also the common ground for TSMC or Nvidia to surpass all competitors and lead far in their respective fields. Another indispensable element is that they are all in the computer chip industry - a rare industry that has existed for about 80 years and has taken a step forward every year compared to the previous year. As computers gradually move human work and life into virtual space, huge profits are also generated during this period, driving chip companies to continue investing in improving technology.

About 15 years ago, NVIDIA CEO Huang Renxun said during a TV program that running fast is not enough, and running fast is a good strategy only when the track is long enough, preferably winding enough. If there is no room for progress and commercial circulation in other industries, a company's continuous investment in technology may not necessarily be able to break away from homogeneous competition.

ASML has caught up with such an unpopular track and, with unwarranted confidence, has continued to invest for 40 years. In a once open, free, and fully competitive global market, it has gathered a large number of suppliers and customers with their brains, funds, and agile hands, as well as some luck, and has come to where it is today.

This is a bit like Barry Werth's summary of the pharmaceutical industry's dark horse, Foton Pharmaceuticals, in "Billion Dollar Molecules". The public often thinks that scientific breakthroughs are dramatic, but in most cases, the opposite is true - breakthroughs are just a small adjustment, a small matter, and a frustrated scientist perseveres with slightly promising data. Everything stems from the moment when a reagent, an experiment, or a method was chosen, that tiny yet crucial node.

Regarding whether later generations can produce lithography machines and advanced chips, there is a rumor in the industry that BYD Chairman Wang Chuanfu said, "These are artificial, not divine."

The people who most agree with Wang Chuanfu may include those from the headquarters of lithography giant ASML. Dutch journalist Marc Hijink, who has been tracking ASML for over a decade, told us, "When I ask this question at ASML, they always say that natural forces are the same in Beijing and the Netherlands. There are no laws of physics that prevent others from making similar machines.".

Currently, 90% of the lithography machines sold globally come from ASML. Its exclusive EUV extreme ultraviolet lithography machine is almost the only choice for producing advanced chips, selling for two to three billion US dollars, making it the most expensive luxury item in Europe. ASML's market value also surpassed luxury goods giant LVMH, the parent company of Louis Vuitton, for the first time this year.

Last week, ASML founder Wim Troost passed away at the age of 98. 40 years ago, it was Trost who put in all his effort that Philips did not completely cut off its loss making lithography business and was willing to let them start their own businesses. At the time of ASML's establishment, Trost was almost sixty years old. The first batch of employees also agreed to join after Philips failed their promise to return to work. This is not the entrepreneurial team that venture capitalists like today.

After years of interviews, Hikink believes that in the end, it was a daring gene and ultimate focus that led ASML to where it is today. "If something is not proven to be impossible, they will feel like they might be able to do it," he said in a video conversation with us.

At the end of last year, Hitchcock's new book "Focus: The ASML Way" (Chinese translation unknown, to be released in October this year) was published in Dutch. The previous ASML biography "The Lithography Giants" only talked about 1996, when ASML was not yet the only choice for cutting-edge chips.

Higgink's Focus complements the growth history of ASML after the millennium. With the support of the management, it provides a more holistic perspective to show how ASML has developed from a start-up company to an industry monopolist in 40 years: a small company with questionable prospects chose the most difficult technical route at the beginning of its entrepreneurship, and continued to focus on one goal for 40 years, eventually becoming the most cutting-edge technology manufacturer in the contemporary era. The resulting machine can carve electronic components on silicon chips that are only a fraction of the size of COVID-19.