Walter Pure Metal Alloy Resistance MSH Series Selection Manual and Purchase Address: Click on the image to enter

hnstshop.com/details/WALTER-MSH.html" target="_blank" >

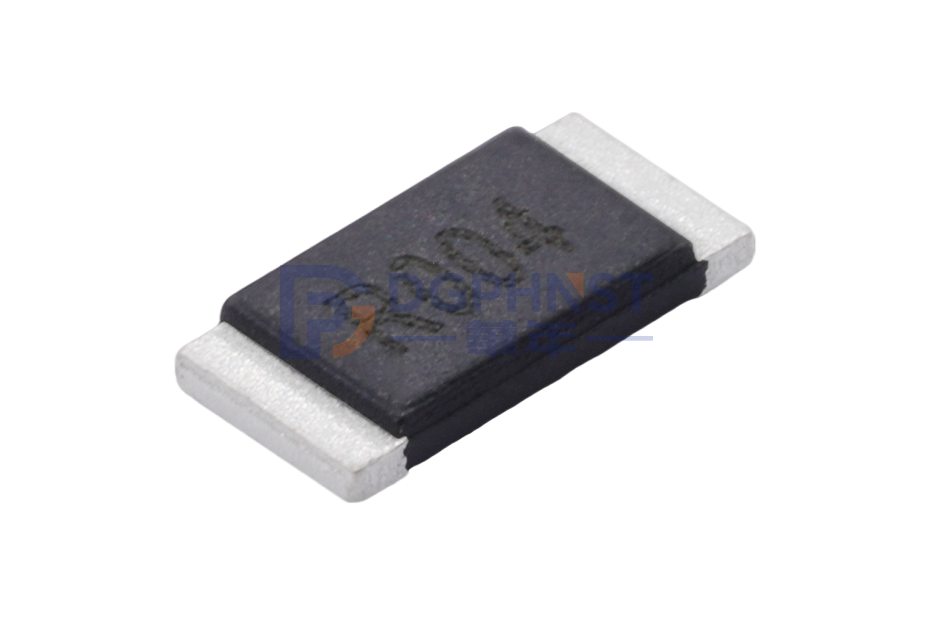

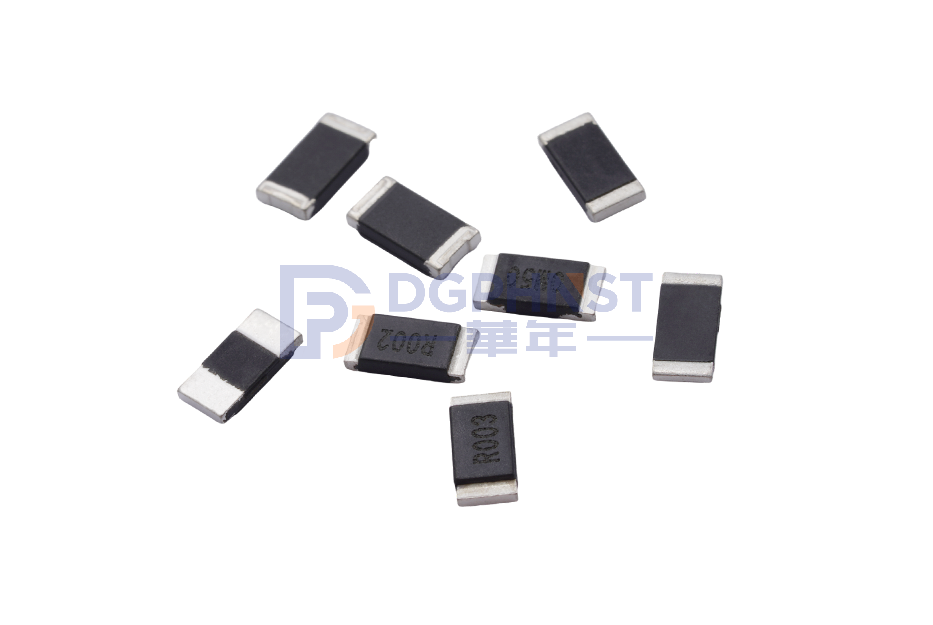

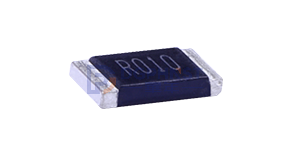

The Walter alloy resistance MSH series is a pure metal alloy resistance, which can be divided into manganese copper alloy and iron chromium aluminum alloy. Manganese copper alloy is an ultra-low resistance alloy with a resistance of 0.5mR~0.003R, and iron chromium aluminum alloy with a resistance of 0.004R~0.056R. The Huade Walter alloy resistance MSH series has a conventional power of 2W and also has a high power of 3W. The Huade pure metal alloy resistance MSH series has strong impact resistance and low-temperature drift performance advantages, and is widely used in products such as power supplies, BMS, new energy, home appliances, etc.

The Suzhou Walter Electronic Walter pure metal alloy resistance MSH series has the following advantages:

1. Wide range of volume options: 2512

2. Wide range of resistance options: 0.5mR~0.056R

3. Wide range of power options: 2W~5W

4. High accuracy: △ ≤ 1%

5. Low temperature coefficient: TCR < 50ppm/℃

6. Excellent low galvanic effect (EMF<0.5uV/℃)

7. How to use RoHS and REACH halogen-free standards

8. The anti welding layer complies with UL94-V0 level

9.Strong impact resistance

The naming rules for the Suzhou Walter Electronics Walter pure metal alloy resistance MSH series are as follows:

| MSH | 2512 | M | 3W0 | R001 | F | I |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

1: Product series: MSH series, metal alloy current detection resistor, short electrode, two terminals, with side conductor.

2: Volume: 2512=6432=6.4*3.2mm

3: Material: M=Manganese copper alloy=MnCu alloy

4: Power: 1W0=1.0Watt

5: Resistance value: R005=0.005R=5mR

6: Accuracy: F=1%, J=5%

8: Product code: internal code or custom code

The selection parameters of Suzhou Walter Electronics Walter pure metal alloy resistance MSH series are shown in the table below:

|

Part Number |

Resistance Value (mΩ) |

Power Rating (Watt) |

Resistance Tolerance (%) |

TCR (ppm/℃) |

| MSH2512M2W0R | 0.5~0.75 | 2 | ±1%(F) | ±150ppm |

| 1~1.5 | 2 | ±0.5%(D)±1%(F) | ±100ppm | |

| 2~4 | 2 | ±0.5%(D)±1%(F) | ±50ppm | |

| MSH2512F2W0R | 5~56 | 2 | ±0.5%(D)±1%(F) | ±50ppm |

| MSH2512M3W0R | 0.5~0.75 | 2 | ±1%(F) | ±150ppm |

| 1~1.5 | 3 | ±0.5%(D)±1%(F) | ±100ppm | |

| 2~4 | 3 | ±0.5%(D)±1%(F) | ±50ppm | |

| MSH2512F3W0R | 5~56 | 3 | ±0.5%(D)±1%(F) | ±50ppm |

Walter pure metal alloy resistance MSH series functional characteristics:

|

Parameter |

Conditions |

Consent Standard |

|

Short time over load |

Power=2.5*Pr ; T=25±2℃ ; t=5s |

± (1.0%+0.5mΩ) IEC60115-1 4.13

|

|

High temp. exposure |

T=+155±2℃; t=1,000hrs |

± (1.0%+0.5mΩ) IEC60115-1 4.25 |

|

Low temp. load life |

T=-55±2℃ ; t=1,000hrs |

± (1.0%+0.5mΩ) IEC60115-1 4.25 |

|

Moisture load life |

Vtest=Vmax, ton=90min,toff=30min, T=60±2℃,RH=95%,1,000hrs |

± (2.0%+0.5mΩ) IEC60115-1 4.25 |

|

Thermal shock |

[-55℃ 30min→ R.T. 3min→ +150℃ 30min→ R.T. 3min] by 100 Continuous Cycles |

± (1.0%+0.5mΩ) IEC60115-1 4.19 |

|

Load life at 70℃ |

Vtest=Vmax ; T=70±2℃ ; t=90min On t=30min Off; 1,000hrs |

± (2.0%+0.5mΩ) IEC60115-1 4.25 |

|

Solderability |

Dipped into solder at 245±5℃ for 3±1s |

The covered area >95% IEC60115-1 4.17 |

|

Resistance to solder heat |

20±1s at 275±5℃ |

±(1%+0.5mΩ) IEC60115-1 4.18 |

|

Substrate bending |

Span between fulcrums: 90mm; Bend width: 2mm; Test board: Glass-epoxy board, Thickness=1.6mm by 10 continuous cycles |

±(1%+0.5mΩ) IEC60115-1 4.33 |

|

Mechanical shock |

a=100G for 11ms, 5 Pulse |

±(1%+0.5mΩ) IEC60115-1 4.21 |