With the continuous development of technology, the Huade wide electrode current detection resistors HTE-M1530 and HTE-C1530 series resistors are widely used in various industries. HTE-M1530 and HTE-C1530, as advanced current detection technologies, have advantages such as high precision, high stability, and high reliability, especially in the fields of power, electronics, communication, energy, etc. Below, we will provide a detailed introduction to the manufacturing and application of Huade wide electrode current detection resistors.

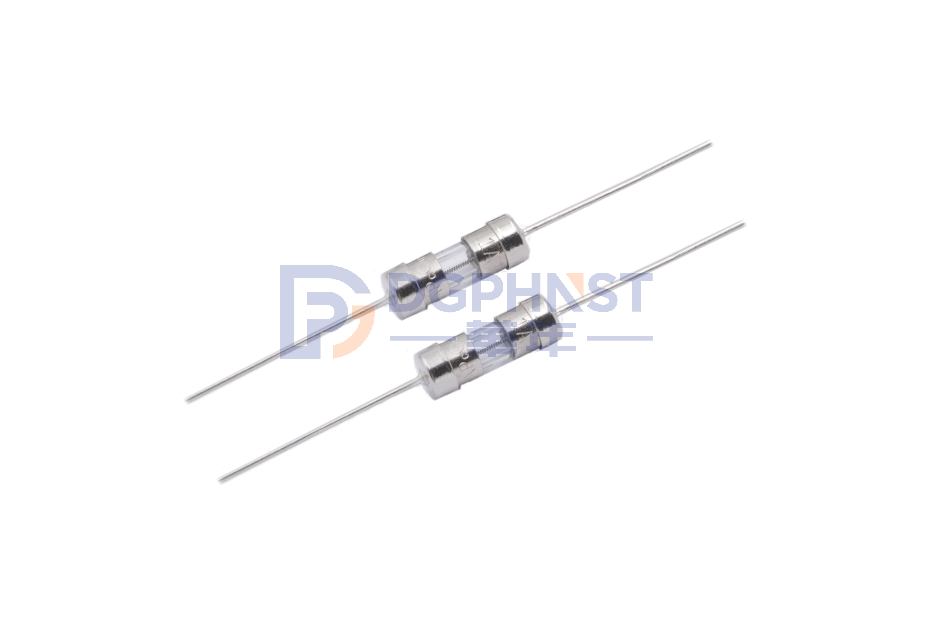

The Huade wide electrode current detection resistor uses high-quality metal materials as the resistor body, such as copper, nickel, etc. These materials have the advantages of high conductivity, high stability, corrosion resistance, etc., which can ensure the long-term stability and reliability of the resistor. The manufacturing process of Huade wide electrode current detection resistor mainly includes precision machining, surface treatment, packaging and other links. In the processing process, advanced CNC machine tools and laser cutting equipment are used, To ensure the accuracy and consistency of the resistance, surface treatment adopts processes such as gold and silver plating to improve the corrosion resistance and conductivity of the resistance. The packaging adopts epoxy resin or ceramic packaging to ensure the stability and reliability of the resistance.

After the completion of manufacturing, the Huade wide electrode current detection resistor needs to undergo strict testing and calibration, including resistance value, accuracy, stability, temperature coefficient, and other indicators. During the calibration process, high-precision calibration equipment and methods are used to ensure the accuracy and consistency of the resistor. It is used for current detection, fault diagnosis, protection control, and other aspects of the power system, and real-time monitoring of the current value, It can timely detect abnormal situations in the power system, ensure the safe and stable operation of the power system, and is used for current detection, power management, energy-saving control, and other aspects of electronic equipment. Real time monitoring of current values can optimize the performance and efficiency of electronic devices, improve their reliability and stability, and can also be used for current detection, signal processing, interference suppression, and other aspects of communication equipment. By monitoring the current value in real-time, the performance and stability of communication equipment can be optimized, and communication quality and reliability can be improved. Used for current detection and efficiency optimization of solar panels, wind power generation equipment, etc. By real-time monitoring of current values, the performance and efficiency of energy equipment can be optimized, and energy utilization efficiency and environmental protection can be improved.

The Ward wide electrode current detection resistor has advantages such as high precision, high stability, and high reliability, and is widely used in fields such as power, electronics, communication, and energy. The manufacturing process includes material selection, manufacturing process, testing and calibration, ensuring the quality and performance of the resistor. In terms of application, Huade wide electrode current detection resistors provide reliable current detection solutions for various fields, playing an important role in ensuring the safe and stable operation of power systems, improving the performance and efficiency of electronic equipment, optimizing the performance and stability of communication equipment, and improving energy efficiency and environmental protection.