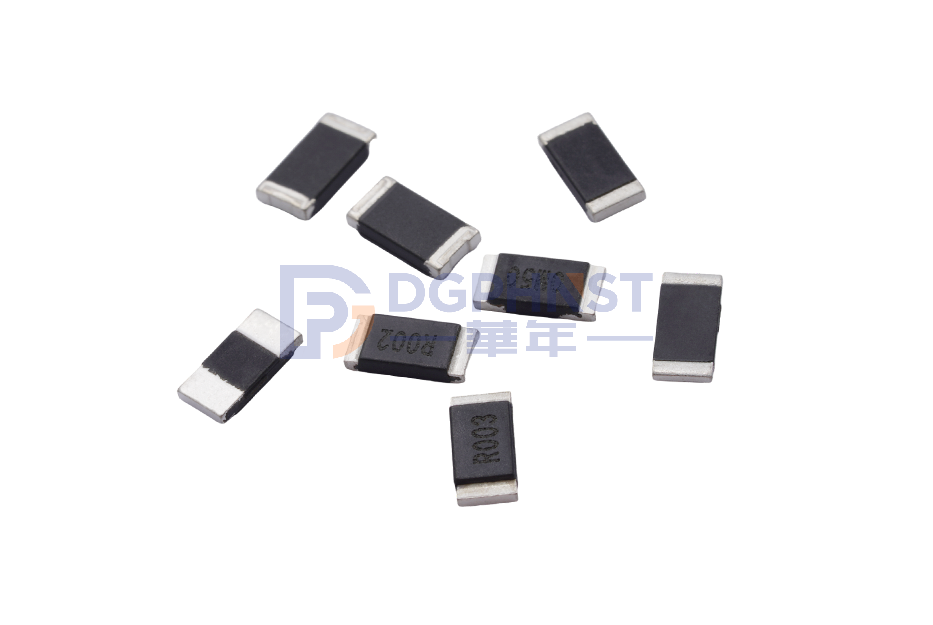

Selection and purchase address of alloy resistors: hnstshop.com/product-list/R09-p1-l10.html" target="_blank" rel="noopener">click on the image link

Alloy resistance and metal foil resistance are two common resistance devices, which have some differences in structure, characteristics, and applications. This article will provide a detailed introduction to the differences between these two types of resistance devices in terms of materials, structure, and resistance characteristics.

Firstly, there is a material difference between alloy resistance and metal foil resistance. Alloy resistance devices are made of alloy resistance materials, typically using copper nickel alloys, nickel chromium alloys, chromium aluminum alloys, etc. These alloys have high electrical resistivity and low temperature coefficient, which can provide stable resistance values. Metal foil resistor components are made of metal foil materials, usually using nickel chromium alloy foil, platinum foil, etc. Metal foil has a low resistivity and a high temperature coefficient, making it suitable for situations with high requirements for resistance changes.

Secondly, there are also structural differences between alloy resistance and metal foil resistance. Alloy resistance devices usually adopt a linear structure, which is made by winding the resistance material around the wire core. This structure is simple, easy to manufacture, and suitable for high-capacity resistors. The metal foil resistor component adopts a thin sheet structure, which means that the metal foil is pasted on the insulation substrate and connected to the external circuit through the outgoing line. This compact structure and small size are suitable for high-precision resistors.

Thirdly, alloy resistance and metal foil resistance also differ in their resistance characteristics. Alloy resistance devices have high temperature stability and low temperature coefficient, and can maintain relatively stable resistance values over a wide temperature range. Metal foil resistor components have higher accuracy and lower temperature drift, which can provide more accurate resistance values. Therefore, metal foil resistance devices are more suitable in situations where high requirements are placed on the accuracy and stability of resistance values.

Fourthly, there are also differences in application between alloy resistance and metal foil resistance. Alloy resistance devices are widely used in electronic and communication devices, and are commonly used in circuits such as current measurement, voltage sharing, and current limiting. Metal foil resistors are often used in high-precision measurement and calibration instruments, such as Voltmeter, Ammeter, bridge, etc. Due to the high accuracy and stability of metal foil resistance devices, they can provide more accurate measurement results.

In summary, there are some differences between alloy resistance and metal foil resistance in terms of material, structure, resistance characteristics, and applications. Alloy resistance devices are suitable for high-capacity resistors and have high temperature stability; Metal foil resistance devices are suitable for high-precision measurement, with high accuracy and low temperature drift. The selection of appropriate resistance devices depends on the specific application requirements.

笔记