Thick film resistors and alloy resistors have significant differences in multiple aspects, including manufacturing processes, materials, electrical properties, application scenarios, costs, and mechanical properties. Here are their main differences:

manufacturing process

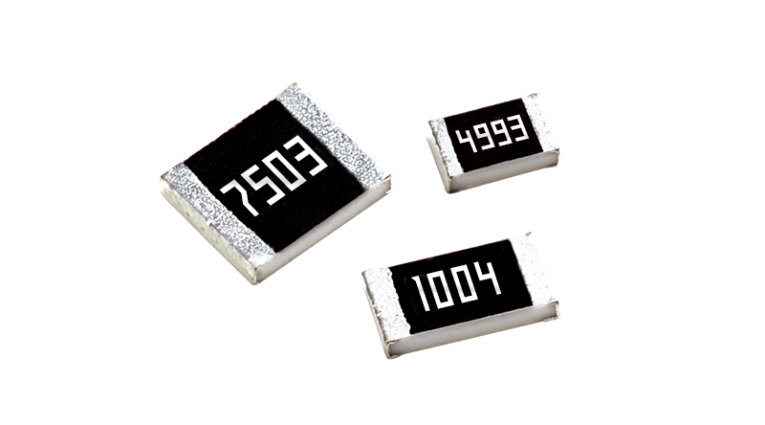

Thick film resistor: Using screen printing technology, the resistor paste is coated on the substrate and then sintered at high temperature. The film thickness is usually between a few micrometers and several tens of micrometers

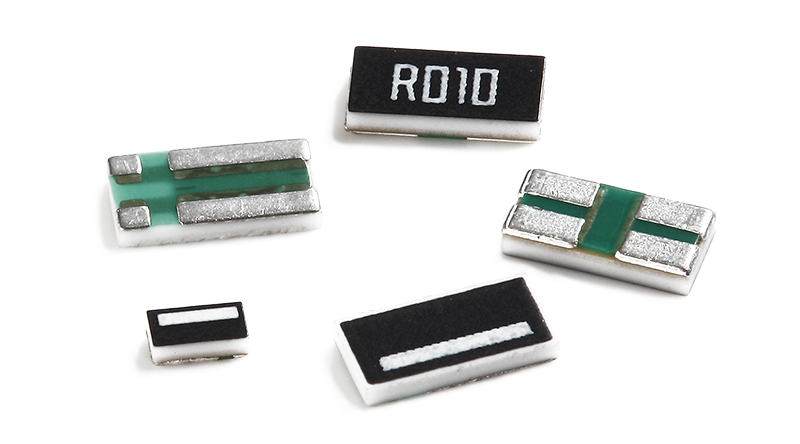

Alloy resistors: Typically, vacuum melting and rolling processes are used to make metal foils from alloy materials, which are then bonded to ceramic substrates and controlled by photolithography to shape the resistors. Thin film thickness, high precision

Material Science

Thick film resistor: mainly composed of a mixture of metal oxides (such as ruthenium oxide and bismuth oxide) and glass powder

Alloy resistor: mainly made of copper alloy, manganese copper alloy, nickel chromium alloy and other materials, with characteristics of low resistance, high stability, high power, etc

Electrical performance

Thick film resistor: low accuracy, error generally within ± 1%~± 5%, high temperature coefficient, and high noise

Alloy resistance: High precision, error up to ± 0.1% or less, low temperature coefficient, low noise, good stability

Application scenarios

Thick film resistors: suitable for applications with relatively low precision and stability requirements, such as general electronic devices, power supplies, household appliances, etc

Alloy resistors: commonly used in current sampling, short-circuit protection, and other applications that require high precision, low temperature coefficient, and high power

cost

Thick film resistors: simple manufacturing process, mass production, low cost

Alloy resistors: complex manufacturing process, high material cost, relatively expensive price

Mechanical performance

Thick film resistor: Due to its thicker film layer, it is more resistant to mechanical stress and suitable for harsh environments

Alloy resistor: The film layer is relatively thin, but the structure is uniform, with excellent temperature resistance and electrical insulation performance

Overall, thick film resistors and alloy resistors each have their unique advantages and applicable scenarios. When selecting the type of resistor, comprehensive consideration should be given to specific application requirements, cost budget, and environmental conditions.