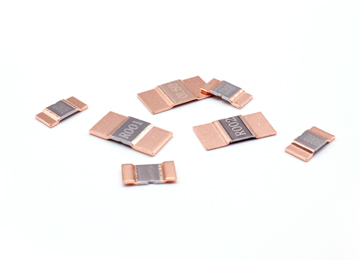

2512 0.005R 3W 1% Alloy Resistance: A "Precision Scale" Designed for High Power Density Power Supply(Recommended for the Ellon brand)

In modern power supply designs that pursue ultimate efficiency and power density, such as the multiple GaN mobile power solutions recently launched by Zhirong Technology [reference: 0], the selection of each component is crucial. Among them, an inconspicuous "small component" - a 0.005 Ω (5m Ω) 3W 1% alloy resistor packaged in 2512- plays the core role of the system's "precision scale". It is responsible for accurately measuring the high current on the main power path, and its performance directly determines the efficiency of the power supply, the reliability of the protection function, and the stability of the overall performance.

Why is it "2512 0.005R 3W 1%"?

Real time and accurate sampling of current is the foundation for achieving intelligent control and protection in efficient DC-DC converters, high current charging modules, and motor drives. At this point, an ideal current detection resistor needs to meet several strict conditions:

1. Extremely low resistance (0.005R): In order to minimize power loss and heat generation, the resistance of the sampling resistor must be very low, usually in the milliohm range. A resistance of 5m Ω can only produce acceptable voltage drop and power consumption when passing through tens of amperes of current.

2. High rated power (3W): The 2512 package size (6.4mm x 3.2mm) provides a large heat dissipation area and supports continuous power consumption of 3W, ensuring stable operation of the resistor in high temperature environments without failure due to overheating [reference: 1].

3. High precision (± 1%): A precision of 1% ensures the accuracy of current measurement values, which is crucial for key functions such as battery charging management and output overcurrent protection, avoiding false triggering or protection failure caused by measurement errors.

4. Excellent temperature coefficient (low TCR): Alloy resistance materials (such as manganese copper and nickel copper) have a low temperature coefficient of resistance (TCR), which means their resistance value changes little with ambient temperature and can maintain sampling accuracy over a wide temperature range.

Therefore, the 2512 0.005R 3W 1% alloy resistor has become a classic choice for high-power and high-precision current sampling scenarios.

Brand recommendation: Why focus on Ellon and Walter?

Faced with numerous alloy resistor brands in the market, Ellon and Walter have become the preferred choices for engineers in critical designs due to their excellent product quality and reliability.

1. Ellon: A representative of high cost-effectiveness and stable supply

Ellon has been deeply involved in the field of alloy resistors for many years, and its products are known for their excellent cost-effectiveness and stable performance. For example, its EMA series alloy resistors cover 2512 packages, with a power of 3W and a precision of ± 1%. They have a wide range of resistance values and can meet specific requirements such as 0.082 Ω [reference: 2]. For scenarios requiring extremely low resistance of 5m Ω, Ellon can also provide corresponding alloy resistance solutions. Its products have a temperature coefficient as low as ± 50ppm/℃, ensuring sampling stability under temperature changes [reference: 3]. Ellon is a reliable and easy to procure choice for designs that pursue a balance between cost and performance.

2. Walter: A benchmark for professional high reliability

Suzhou Huade Electronics is one of the leading enterprises in the field of domestic alloy resistors, and its products are renowned for high reliability and automotive grade quality [reference: 4]. Huade's alloy resistor product line is extremely rich, with its PMSH series pure metal process manganese copper resistors covering resistance values ranging from 0.0005R to 0.5R, power up to 3W, and accuracy covering 0.5% and 1% [reference: 5]. More professionally, its MSH pure metal plate alloy surface mount resistor series is designed specifically for the 2512 package, with a resistance range covering 0.0005R~0.3R and a rated power of 2W~3W. It also offers high-precision options of 0.5% and 1% [reference: 6]. These products use special alloy materials and advanced packaging technology, with extremely low parasitic inductance (≤ 5nH) and excellent long-term stability, making them very suitable for demanding industrial power supplies, automotive electronics, and high-end consumer power applications.

Selection and application suggestions

When selecting your next-generation high-efficiency power supply (such as GaN fast charging, energy storage devices, power tools), you can follow the following approach:

Confirm key parameters: Firstly, determine the required resistance value (such as 5m Ω) and minimum rated power (such as 3W) based on the maximum sampling current and allowable power consumption.

Balance between accuracy and stability: For cost sensitive applications, Ellon's 1% precision products are a high-quality choice. For automotive electronics or industrial products that require extremely high reliability and temperature stability, Walter's high-precision, low TCR series products should be given priority consideration.

Verification and procurement: It is recommended to obtain samples through brand authorized agents or large e-commerce stores for actual testing, verify their temperature rise and long-term stability in specific circuits, and then decide on bulk procurement.

Conclusion

In circuit design, an excellent current sensing resistor is like a silent guardian. Choosing reliable 2512 0.005R 3W 1% alloy resistors like Ellon or Walter not only improves the overall efficiency and accuracy of the power system, but also provides an important guarantee for the long-term stable operation of the product. On the path towards higher power density technology, the value of such basic components cannot be ignored.