The following is a comprehensive analysis of the future development trend of alloy resistors, combined with industry trends, technological innovation, and market data, to sort out its evolution path from multiple dimensions:

1、 Market growth and regional pattern evolution

Scale and growth rate

The global alloy resistor market is expected to reach approximately 4.325 billion yuan in 2023 and 9.648 billion yuan in 2030, with a compound annual growth rate (CAGR) of 12.66%. The core driving force comes from the popularization of new energy vehicles (accounting for 25% of downstream applications), 5G communication, IoT devices, and consumer electronics.

Strengthening China's dominant position

China (including Taiwan) will account for 71% of the global market in 2023, and is expected to rise to 75% by 2030. The mainland's production capacity accounts for 61% of the world's total, and technological upgrades have further expanded its share. Policies such as the "Action Plan for the Development of Basic Electronic Components Industry" are accelerating domestic substitution.

2、 Technological innovation direction

Breakthrough in Materials and Craftsmanship

High precision and low-temperature drift: Manganese copper alloy (temperature drift ± 20ppm/℃) and Kama alloy (± 15ppm/℃) dominate the high-end market, meeting the requirements of automotive grade AECQ200.

AI Empowered Manufacturing: For example, Minghui Electronics has introduced AI quality inspection, which has increased the defect recognition rate to 98% and reduced labor costs by 80%; Pusenmei Microelectronics optimizes high-temperature stability through structural design patents.

Green Manufacturing: Environmentally friendly materials and processes reduce energy consumption and comply with EU sustainability standards.

Product design innovation

Multi functional integration: resistor integrated temperature/humidity sensing function, adapted to the needs of smart devices.

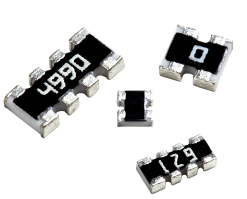

Miniaturization and high power: 0603 packaged alloy resistors have the fastest growth rate, in response to the trend of consumer electronics becoming thinner and lighter.

3、 Localization process and competitive situation

Domestic substitution acceleration

The high-end market is still dominated by Japanese, Korean, and Taiwanese companies (such as Weishi and Qiankun Technology), but domestic companies such as Fujitsu Electronics have seized market share with their customization capabilities (such as FCM pure alloy series) and cost advantages. Under policy promotion, the penetration rate of domestic mid to high end products will increase from 30% to 50%.

Centralized competitive landscape

The top 3 global manufacturers (Guoju, Dayi Technology, Junwei Electronics) account for 44.8% of the market share, while the second tier (Weishi, Isabellenh ü tte, etc.) account for 30.4%. The integration of future mergers and acquisitions will intensify, and the head effect will be significant.

4、 Expansion of emerging application scenarios

New energy vehicles as the core growth pole

The usage of new energy vehicles is significantly higher than that of fuel vehicles, and the market for automotive alloy resistors is expected to reach $15.13 million by 2030 (CAGR 13.1%). Inverter and BMS system requirements drive the increase of high surge resistance.

Renewable Energy and Intelligent Equipment

Photovoltaic/wind power inverters rely on high reliability resistors, corresponding to a market growth rate of over 8%.

IoT devices and smart homes drive the demand for miniaturization and low-power resistors, with mobile applications accounting for 19.52% (CAGR 5.61%).

5、 Industrial chain synergy and ecological construction

Supply chain intelligence

Based on big data and AI, the global supply network optimizes inventory turnover and shortens delivery cycles by 13 days.

Deepening cross-border cooperation

Joint research and development between material companies and machine manufacturers (such as Huawei Cloud and Minghui Electronics collaborating on AI quality inspection) to accelerate the industrialization of technology.

Performance Comparison: Application Trends of Mainstream Alloy Resistance Materials

|Material Type | Temperature Coefficient (ppm/℃) | Core Advantages | Dominant Application Scenarios | Market Share Trends|

|Manganese copper alloy | ± 20 | Ultra high stability, low temperature drift | Precise current sampling, BMS system | Stable growth|

|Iron chromium aluminum alloy | ± 50~100 | High temperature resistance, low cost | Industrial heaters, automotive power modules | Medium low speed growth →|

|Kama alloy | ± 15 | High stability+temperature resistance | Aerospace and military equipment | High end market growth|

|Nickel copper alloy | ± 30 | No parasitic inductance, excellent high-frequency characteristics | 5G base station, communication power supply | Rapid growth|

The future of alloy resistors will present a three in one development of "high-precision, intelligent, and green":

Market: China dominates global production capacity, domestic substitution breaks through to high-end;

Technology: AI and new materials drive performance leaps, and integrated functionality becomes mainstream;

Application: New energy and the Internet of Things drive incremental growth, leading to a surge in customized demand.

Enterprises need to focus on breaking through technological barriers and ecological synergy in order to seize market opportunities worth billions.