This article will provide a comprehensive explanation of the current sensing resistance advantages, application fields, and functional characteristics of the Suzhou Electronics hnstshop.com/maker/WALTER.html" target="_blank" >Walter brand.

Suzhou Electronics (Walter) has successfully developed and achieved mass production of surface mount ceramic metal foil 2W precision current sensing resistors (CSR), and can provide a minimum packaging size specification of 0201. In order to meet the design requirements for circuit board dimensions applied by engineers, Walter has developed and mass-produced a full range of products from 0201 to 5931. Small volume CSR can replace large size CSR that occupies a lot of space and is used to save space.

The CSR series, from raw materials to finished product manufacturing, is independently developed and produced using exclusive secret formulas, providing high-power and low resistance products.

The Walter electronic CSR structure is carefully crafted from ceramic metal foil and constantan or manganese copper resistance elements. Its resistance has low inductance (H<5.0nH) and low galvanic effect (EMF<0.5uV/℃) at high frequencies of 1GHz.

Walter products have passed rigorous testing by world leading manufacturers. Its ultra-low resistance and high-precision CSR series is the best alternative to traditional winding and lead-containing products, with features including:

1.high-precision △R<1%

2.TCR value of advantages(TCR<40ppm)

3.Excellent low galvanic effect(EMF<0.5uV/℃)

4.high power

5.High frequency response(H<5.0nH)

6.High reliability (better than the 2000H US military regulation Mil-202, Method 107G reliability testing standard)

7.Compliant with RoHS/REACH standards, halogen-free

8.Resistance alloy plate

9.The anti welding layer meets the requirements of UL-94-V0

10.Excellent overload and pulse capability

11.Hypoallergenic immunity(<0.05uH at 10MHz)

12.Easy to assemble (suitable for surface mount technology)

The main application areas of Walter Electronics include:

Industrial electronics: power supply, management of power converters, frequency converters, batteries (packs), power management, motor controllers, etc.

Automotive electronic control; Control system, power transmission, light source, base, central control, switch, etc.

Others: Major appliance, 3C products, communication products, medical products, computers and peripheral equipment, mobile phones, etc.

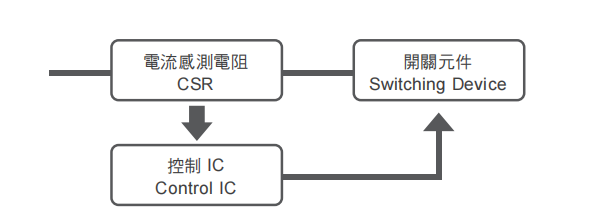

Working principle of Walter current sensing resistor CSR:

CSR is a current sensing resistor element, which is a detection element in the circuit that uses feedback voltage difference to assist the control IC in determining the current condition at that time. When the control IC obtains a signal from the CSR end, it informs the component on the power circuit where it is located that actions and measures should be taken. Its function transmits the measured information to the IC comparator to determine subsequent actions, so the progress of CSR is quite important. We can provide high-precision (△ R<1%) and high-power (P>3W) CSR.

Walter current sensing resistor CSR functional characteristics:

|

Parameter |

Conditions |

Consent Standard |

|

Short time over load |

Power=2.5*Pr ; T=25±2℃ ; t=5s |

± (1.0%+0.5mΩ) IEC60115-1 4.13

|

|

High temp. exposure |

T=+155±2℃; t=1,000hrs |

± (1.0%+0.5mΩ) IEC60115-1 4.25 |

|

Low temp. load life |

T=-55±2℃ ; t=1,000hrs |

± (1.0%+0.5mΩ) IEC60115-1 4.25 |

|

Moisture load life |

Vtest=Vmax, ton=90min,toff=30min, T=60±2℃,RH=95%,1,000hrs |

± (2.0%+0.5mΩ) IEC60115-1 4.25 |

|

Thermal shock |

[-55℃ 30min→ R.T. 3min→ +150℃ 30min→ R.T. 3min] by 100 Continuous Cycles |

± (1.0%+0.5mΩ) IEC60115-1 4.19 |

|

Load life at 70℃ |

Vtest=Vmax ; T=70±2℃ ; t=90min On t=30min Off; 1,000hrs |

± (2.0%+0.5mΩ) IEC60115-1 4.25 |

|

Solderability |

Dipped into solder at 245±5℃ for 3±1s |

The covered area >95% IEC60115-1 4.17 |

|

Resistance to solder heat |

20±1s at 275±5℃ |

±(1%+0.5mΩ) IEC60115-1 4.18 |

|

Substrate bending |

Span between fulcrums: 90mm; Bend width: 2mm; Test board: Glass-epoxy board, Thickness=1.6mm by 10 continuous cycles |

±(1%+0.5mΩ) IEC60115-1 4.33 |

|

Mechanical shock |

a=100G for 11ms, 5 Pulse |

±(1%+0.5mΩ) IEC60115-1 4.21 |

Selection guide for current sensing resistor CSR products:

Step 1: Select the required resistance value in the circuit

Step 2: Select the accuracy required for the resistance value, which is the minimum error value

Step 3: Confirm the maximum current that frequently flows through the component in the circuit

Step 4: Calculate the minimum rated power required for this component based on this current. When selecting this component, it must be greater than the actual power used

Step 5: Select the required size based on the design space size

Step 6: Consideration of the presence or absence of thermoelectric electromotive force (EMF)

For example, a design engineer needs to use a current sensing element (CSR) for the OCP protection at the back end of the power supply. Because of the circuit design, it needs to use 5m Ω, and because the Power management integrated circuit it uses is highly sensitive and the allowable resistance error is small, it needs to select a resistance accuracy with an error less than 1%. In addition, the current that flows frequently is about 15A, so the power consumption that the resistance needs to withstand is P=1.125W. Moreover, the system does not need to consider the EMF effect, Therefore, the selected model is MSH2512F2W0R005F.