We all know that precision resistors require high precision and reliability. Can high-precision resistors truly guarantee their high precision and stability? This is not absolute, but related to the environment it is used in. Below, we will give a simple example to illustrate.

When measuring the resistance, a 100% electrical performance test is conducted, and the product itself is 100% qualified upon leaving the factory. So, if the product itself is qualified, it does not necessarily mean that it is qualified in actual use on the client side, because it depends on factors such as the customer's actual product application, circuit layout, and usage environment.

The main core parameters of resistance include volume, resistance value, accuracy, power, temperature drift, voltage, and temperature, which are key parameters. Each parameter will have certain changes in different environments, so even the resistance of the same parameter will have different changes in different applications. We can provide examples of precision resistors below.

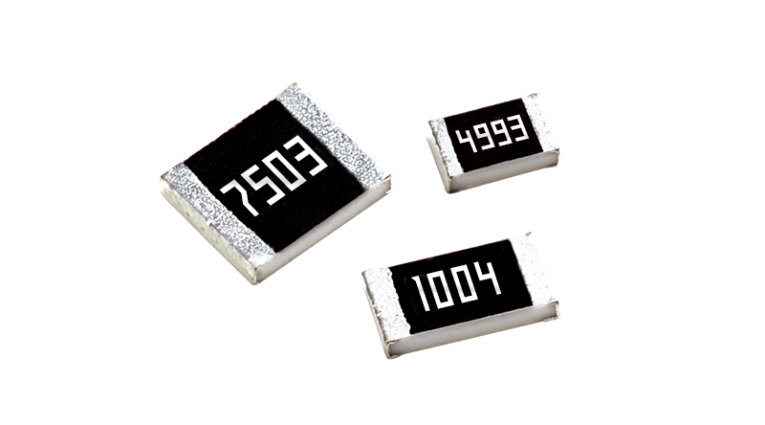

Precision resistors can be classified into thin film precision resistors and thick film precision resistors, mainly due to differences in materials and processes.

Let's take the resistance parameters of EVER OHMS as an example: 1206 100R 0.1%

If this parameter is met, there will be the following series and models, and the actual characteristics of the product will also differ:

TR1206B100RP0550Z 1206 100R 0.1% 50ppm/℃ Thin film precision resistor

TR1206B100RP0525Z 1206 100R 0.1% 25ppm/℃ Thin film precision resistor

TP1206B100RP0525Z 1206 100R 0.1% 25ppm/℃ Thin film precision resistor

CR1206B100RP05Z 1206 100R 0.1% 100ppm/℃ Thick film precision resistor

QR1206B100RP0550Z 1206 100R 0.1% 50ppm/℃ Thin film precision resistor (vehicle standard)

CRH1206B100RP05Z 1206 100R 0.1% 100ppm/℃ Thick film precision resistor (high power)

TH1206B100RP0525Z 1206 100R 0.1% 25ppm/℃ Thin film precision resistor (high power)

TQ1206B100RP0525Z 1206 100R 0.1% 25ppm/℃ Thin film precision resistor (vehicle standard)

Thin film precision resistor

The above is an example model, which is only 0.1% high-precision. If it is 0.5% precision, there will be more models and series, such as high-power series, anti surge series, anti vulcanization series, automotive specification series, high-voltage series, thin film series, thick film series, and so on. It still depends on the specific usage environment. For example, vehicle regulations require the use of vehicle regulations. For high-temperature scenarios, high-temperature resistant ones should be used. For high-power applications, CRH or QRH can be used. For thin film low-temperature tickets, TR can be used, and so on. If ordinary thin film TR series products are applied to resistance against vulcanization or surge, there may be a risk of corrosion or impact damage to the products.

That is to say, when selecting precision resistors, it is necessary to consider the actual application scenario, otherwise there is a risk of damage.