TX / TY series fuse is a thermistor hnstshop.com/product-list/F06-p1-l10.html" target="_blank">temperature fuse, can automatically cut off the circuit according to the change of temperature, protect the safety of the circuit and equipment. Liangsheng TX / TY temperature fuse is one of the more used, often used in refrigerators, air conditioners, washing machines, hair dryer, rice cookers and other household electrical equipment. These two series of parameters in addition to the current is different, many parameters are the same, it is easy to mistake the model, so the choice must be confirmed many times, so as not to cause unnecessary losses.

Selection process for TX / TY Series Fuses: Safety certification, such as UL specification or IEC specification.

Structure size: according to the space of the circuit design to determine the size, such as length, diameter, whether with lead, etc.

Rated voltage: must be greater than or equal to the actual application voltage, generally 24V, 32V, 63V, 125V, 250V, etc.

Break capacity: shall be greater than the maximum fault current in the circuit.

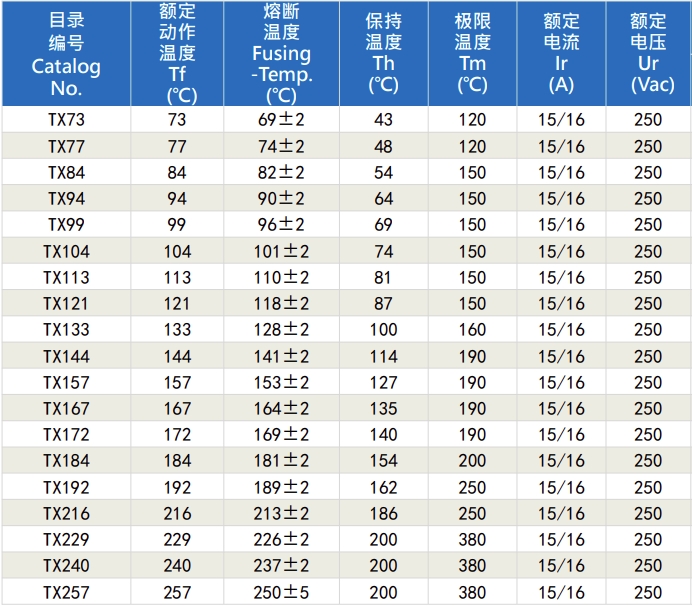

Rated current: See the following chart.

The TX / TY series installation location

Hao Li to temperature fuse needs to be installed in the circuit may appear overload or short circuit, in order when the circuit, protect the safety of the circuit and equipment, before installing the fuse, often need to determine the temperature fuse before installing the temperature fuse, need to prepare the following tools and materials, cross screwdriver, electric iron, paper towel or cotton swab, good temperature fuse, fuse clip or wire clip, heat shrink pipe (optional).

The TX / TY series of installation steps

Use a cross screwdriver to disassemble the circuit board or equipment housing requiring a temperature fuse installation.

Place the good win temperature fuse in the determined installation position and place it in the fuse clip or wire clip. If there is no fuse clip or wire clip, attach the fuse to the wire using a heat shrink tube.

Use electric soldering iron to melt the solder, weld the bright temperature fuse on the wire, when welding, be careful not to burn the wire insulation layer or burn the circuit board.

Use paper towels or cotton swabs to clean up the excess solder and impurities to ensure that the connection between the circuit board and the smart temperature fuse is stable.

Reassemble the circuit board or equipment housing together to ensure that the smart temperature fuse works properly.