Filter capacitors play a very important role in switching power supplies, and how to correctly select filter capacitors, especially the selection of output filter capacitors, is a concern for every engineering and technical personnel.

On the power filtering circuit, we can see various capacitors with different capacitance values, such as 100uF, 10uF, 100nF, 10nF, etc. How are these parameters determined?

In a 50Hz power frequency circuit, ordinary electrolytic capacitors are used, with a pulsating voltage frequency of only 100Hz and a charging and discharging time of milliseconds.

To achieve a smaller pulsation coefficient, hundreds of thousands of capacitors are required μ F. Therefore, the goal of ordinary low-frequency aluminum electrolytic capacitors is mainly to improve capacitance, and the capacitance, loss tangent value, and leakage current of the capacitor are the main parameters for distinguishing its advantages and disadvantages.

The output filtering electrolytic capacitor in switch mode power supply has a sawtooth voltage frequency of tens of kHz, even tens of MHz, and capacitance is not its main indicator.

The standard for measuring the quality of high-frequency aluminum electrolytic capacitors is the impedance frequency characteristic, which requires a lower equivalent impedance within the operating frequency of the switching power supply, and has a good filtering effect on the high-frequency peak signals generated during the operation of semiconductor devices.

Ordinary low-frequency electrolytic capacitors begin to exhibit inductance around 10kHz and cannot meet the requirements of switching power supply usage.

The high-frequency aluminum electrolytic capacitor specialized for switch mode power supply has four terminals, with the two ends of the positive aluminum sheet being led out as the positive electrode of the capacitor, and the two ends of the negative aluminum sheet being led out as the negative electrode.

The current flows from one positive terminal of the four terminal capacitor, passes through the inside of the capacitor, and then flows from the other positive terminal to the load; The current returned from the load also flows from one negative end of the capacitor, and then from another negative end to the negative end of the power supply.

Due to the excellent high-frequency characteristics of the four terminal capacitor, it provides an extremely advantageous means to reduce voltage ripple components and suppress switch spike noise.

High frequency aluminum electrolytic capacitors also have a multi-core form, which divides the aluminum foil into shorter sections and connects them in parallel with multiple pieces to reduce the impedance component in the capacitance.

And using low resistivity materials as lead out terminals improves the capacitor's ability to withstand large currents.

Digital circuits must operate stably and reliably, the power supply must be clean, and energy replenishment must be timely, that is, filtering and decoupling must be good.

What is filtering decoupling? Simply put, it means storing energy when the chip doesn't need current, and I can replenish energy in a timely manner when you need current.

Don't tell me this responsibility is not for DCDC or LDO? Yes, they can handle it at low frequencies, but high-speed digital systems are different.

Let's first take a look at capacitors. The function of capacitors is simply to store charges. We all know that capacitor filtering should be added to the power supply, and a 0.1uF capacitor should be placed on the power pin of each chip to decouple.

Wait, why do I see that the capacitors next to the power pins of some board chips are 0.1uF or 0.01uF? Is there any particular requirement?

To understand this path, one needs to understand the actual characteristics of capacitors. An ideal capacitor is just a memory of a charge, that is, C.

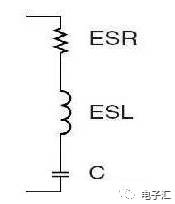

However, the actual manufactured capacitors are not so simple. When analyzing the integrity of the power supply, the commonly used capacitor model is shown in the following figure.

ESR in the figure is the series equivalent resistance of the capacitor, ESL is the series equivalent inductance of the capacitor, and C is the true ideal capacitor.

ESR and ESL are determined by the manufacturing process and materials of capacitors, and cannot be eliminated. What impact do these two things have on the circuit.

ESR affects the ripple of the power supply, while ESL affects the filtering frequency characteristics of the capacitor.

We know that the capacitance impedance Zc of a capacitor is 1/ ω C. Inductive reactance of inductance Zl= ω L( ω= 2 π f), the actual complex impedance of the capacitor is Z=ESR+j ω L-1/j ω C=ESR+j2 π fL-1/j2 π fC.

It can be seen that when the frequency is very low, the capacitor plays a role, while when the frequency is high to a certain level, the role of the inductor cannot be ignored. At higher frequencies, the inductor plays a dominant role, and the capacitor loses its filtering function.

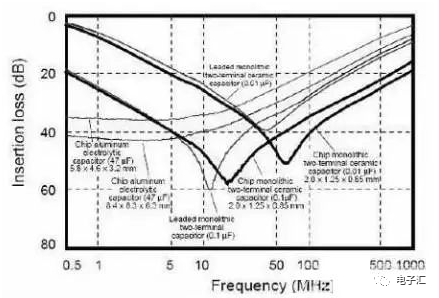

So remember, at high frequencies, capacitors are not just capacitors. The actual filtering curve of capacitors is shown in the following figure:

As mentioned above, the equivalent series inductance of a capacitor is determined by the manufacturing process and material of the capacitor. The actual ESL of a SMT ceramic capacitor ranges from a few nH to several nH, and the smaller the package, the smaller the ESL.

From the filtering curve of the capacitor above, we can also see that it is not flat. It is like a 'V', which means it has frequency selection characteristics. At times, we hope it is as flat as possible (board level filtering in the front stage), and sometimes we hope it is as sharp as possible (filtering or notch).

What affects this characteristic is the quality factor Q of the capacitor, Q=1/ ω CESR: The larger the ESR, the smaller the Q, and the flatter the curve. Conversely, the smaller the ESR, the larger the Q, and the sharper the curve.

Tantalum capacitors and aluminum electrolysis usually have a relatively small ESL and a large ESR, so tantalum capacitors and aluminum electrolysis have a wide effective frequency range, which is very suitable for front-end board level filtering.

That is to say, in the input stage of DCDC or LDO, larger tantalum capacitors are often used for filtering.

And place some 10uF and 0.1uF capacitors near the chip to decouple, ceramic capacitors have a very low ESR.

After saying so much, should we place 0.1uF or 0.01uF near the pins of the chip? Below is a list for your reference:

| frequency range/hz | Capacitance value |

| DC-100K | Tantalum capacitors or aluminum electrolysis above 10uF |

| 100K-10M | 100nF (0.1uF) ceramic capacitor |

| 10M-100M | 10nF (0.01uF) ceramic capacitor |

| >100M | 1nF (0.001uF) ceramic capacitor |

So, in the future, don't see a 0.1uF capacitor in everything. In some high-speed systems, these 0.1uF capacitors won't work at all.